Connectors Solutions

Challenge

Connectors make reliable and efficient electrical connections between different parts of an electronic or electrical system. They’re used in a wide array of applications such as consumer electronics, computing and networking, telecommunications, automotive, medical devices, and energy.

This diversity underscores their importance in virtually all technological domains– connectors not only provide links between components but also ensure the reliability, efficiency, and safety of electronic systems across a broad spectrum of applications.

Manufacturing connectors involves complex processes that require high precision and reliability. The inspection of these components poses several challenges due to their small size, the variety of materials and plating used, high volume production, and the stringent performance requirements.

To overcome these challenges, connectors manufacturers are investing in advanced inspection technologies.

Applications

UnitX automates inspection across all connectors manufacturing processes such as:

Metal Component Manufacturing

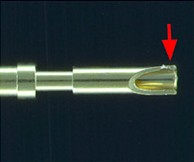

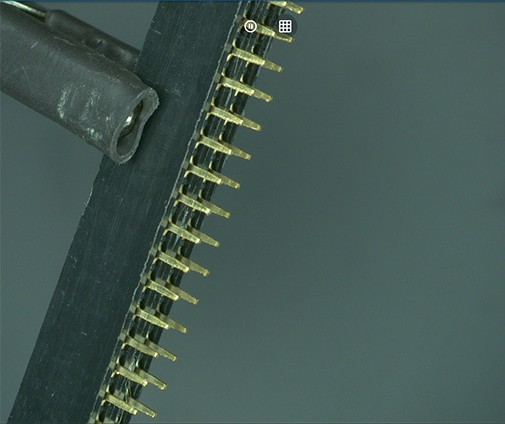

Connectors often include metal components for conducting electricity, such as pins and contacts. These parts are typically made with stamping or machining processes.

UnitX inspects contacts and pins for stamping and machining defects that can impact the functionality, reliability, and performance of the final connector product.

Plating

Metal components might be plated with materials such as gold or nickel to improve conductivity and corrosion resistance.

UnitX inspects metal component surfaces for plating defects that can impact the reliability and performance of the final connector product.

Plastic Component Manufacturing

Connectors require housing, an outer cover that protects internal components, provides electrical insulation, and ensures alignment for mating. Housings are typically made via injection molding of plastic, where molten plastic is injected into molds and cooled to form desired shapes.

UnitX inspects housings for injection molding defects that can impact the connector component’s physical integrity, cause short circuits, and compromise functionality.

Assembly

Finally, components are assembled into the final connector: contacts are fastened into housing, electrical wires are terminated onto the connector contacts to establish electrical connection, additional internal components like insulators are positioned, and finally the connector housing is joined together.

UnitX inspects the final connector for assembly defects such as component misalignment, missing components, damaged components, incorrect orientation, soldering defects, contamination, and loose connections that can impact its functionality, reliability, and performance.

Solutions

AI Only

(via integration with third party vision systems)

Rapid deployment of UnitX AI with existing systems. UnitX’s CorteX integrates with traditional third party vision systems to provide defect detection faster and more accurately where you already have vision systems deployed

Imaging + AI

Best-in-class inspection using UnitX imaging and AI. UnitX’s OptiX dynamically illuminates parts while UnitX’s CorteX detects variable defects across the entire connectors manufacturing process

Advantages

UnitX’s unique advantages ultimately help connectors manufacturers ensure quality while improving yield:

Reduced cost

100% automated inline inspection replaces need for manual inspectors

Increased throughput

High-speed imaging & AI inference speeds that match cycle times

Reduced escapes

Accurately detects defects that are highly variable and complex in shape, size and presentation

Reduced overkill

Adjustable thresholds to distinguish unacceptable defects from defects that are within tolerances

Faster deployment

Sample-efficient AI that requires as few as 5 images to train

Increased traceability; reduced impact of recalls

All inspection data with identifiers referenceable in one central platform

Introducing

UnitX

UnitX provides AI vision to help manufacturers automate inspection. Connectors manufacturers use UnitX solutions to detect defects for various connector types (like headers, board-to-board, wire-to-board, etc.) and across all connector manufacturing processes (from forming to plating to injection molding to assembly to termination).

Connectors Application Examples

To learn more about how UnitX can automate inspection for you, please contact us here