FleX The World's Most Accurate Inline Visual Inspection System

Achieve the lowest escape and scrap rate with FleX’s advanced AI & imaging technology.

FleX: The World's Most Accurate Visual Inspection System for Inline Manufacturing

FleX is designed to tackle the most complex visual inspection challenges with the best

accuracy and deployment speed across inline production environments.

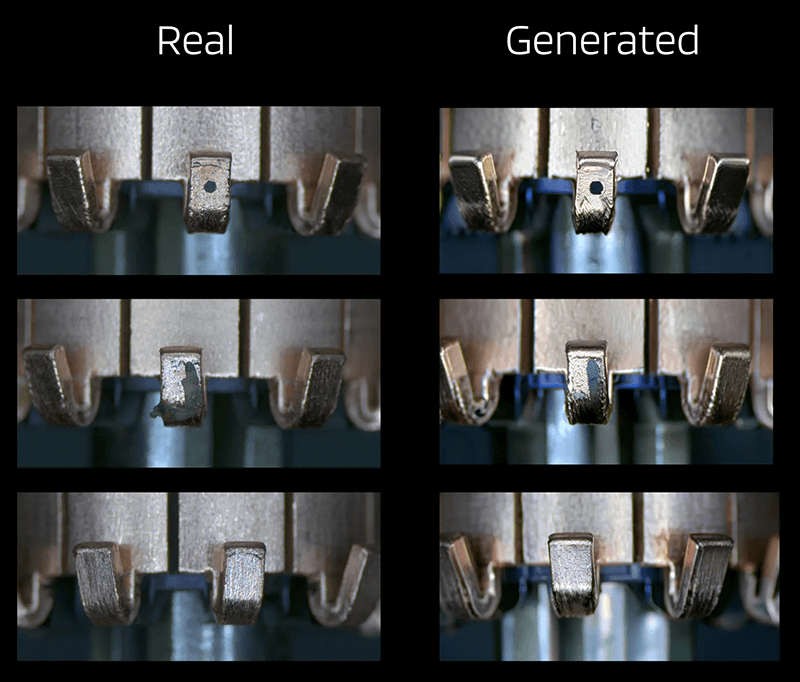

Software to generate synthetic data to enrich training data set. Achieve higher accuracy faster

High performance edge compute systems for 100% inline inspection in production, MES/FTP integration and traceability data saving

(Hardware, AI Image Processing System)

Centralized training system to learn random complex defects, location, dimensional gauging, QR/bar code detection on high-resolution images.

(Software-Defined Lighting)

Software-defined lighting system that dynamically optimize feature contrast across material surfaces and geometries. Accommodates large field of view (FOV) and high-resolution imaging, supporting 2.5D depth-dependent defect detection.

Integration-ready with broad PLC compatibility, offering flexibility to integrate and customize for custom production needs.

Achieve the best OEE of Your Production Line

FleX delivers the lowest scrap rate, rapid for inline production.

Improved Detection Accuracy

- Generative AI enhance to 9× fewer escapes using synthetic data.

- 2.5D imaging for depth-defect detection.

- High-resolution support on single images up to 50 MP.

- Works with large imaging platforms at up to 500mm field of view.

Rapid Deployment

- Easy setup with No-code PLC integration via ComX.

- Faster training: 3× quicker with balanced (FA/FR) to cut scrap.

- Feature-centric AI adapts fast to high-mix and new part types.

Broader Integration and Compatibility

- Expanded PLC Protocol Support: Broader compatibility with all major PLC protocols, including robust trigger integration.

- Flexible Camera Options: GigE camera compatibility for versatile deployment.

- Open Ecosystem: SDK available for third-party partners to build custom software extensions.

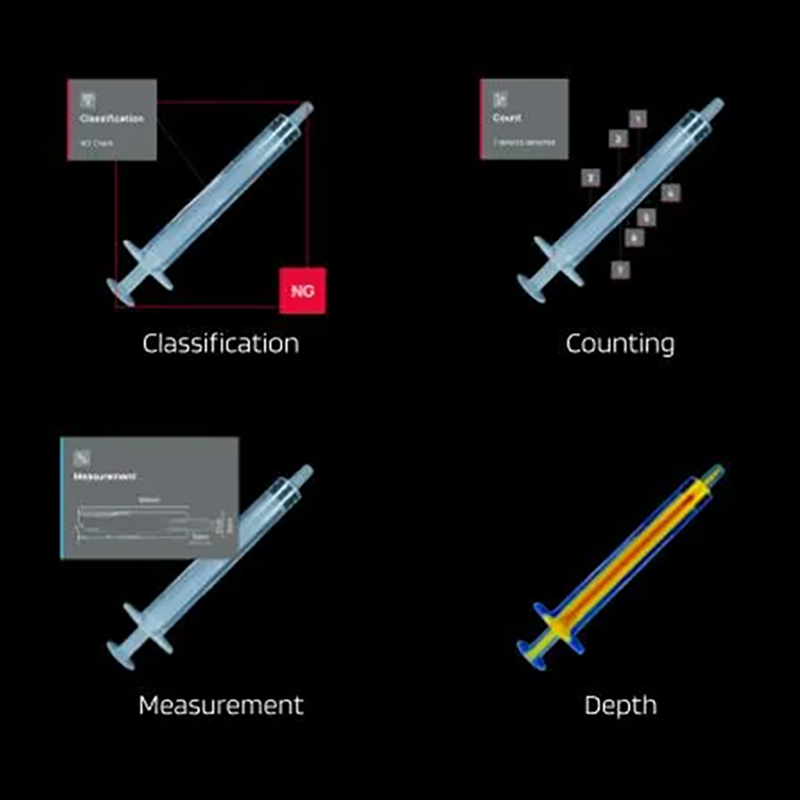

Expanded Capabilities

- Dimensional measurement.

- QR code scanning, and OCR.

How FleX Elevates Your Quality

FleX is designed for quick deployment and seamless

integration into your existing production lines.

Tailored for all Industries

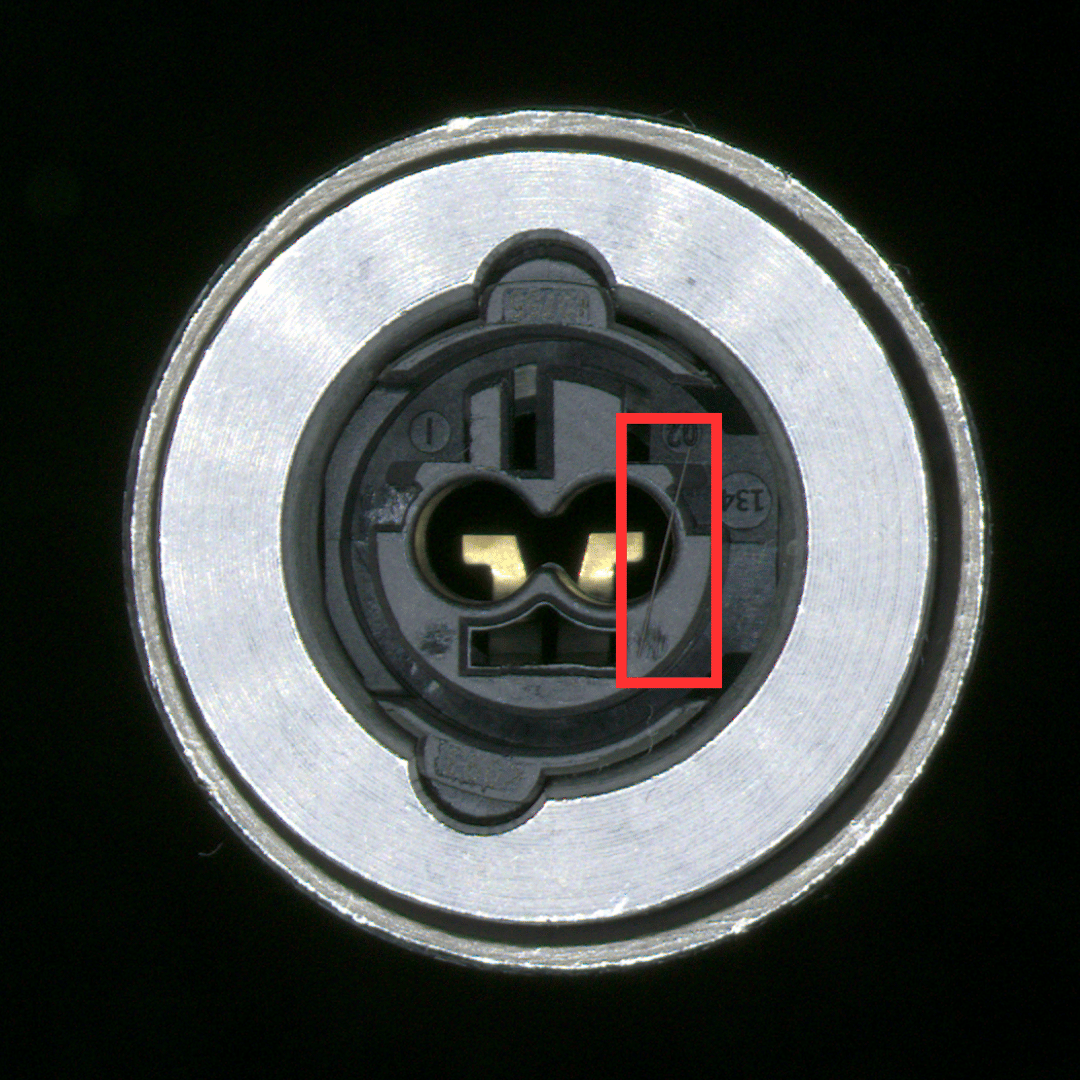

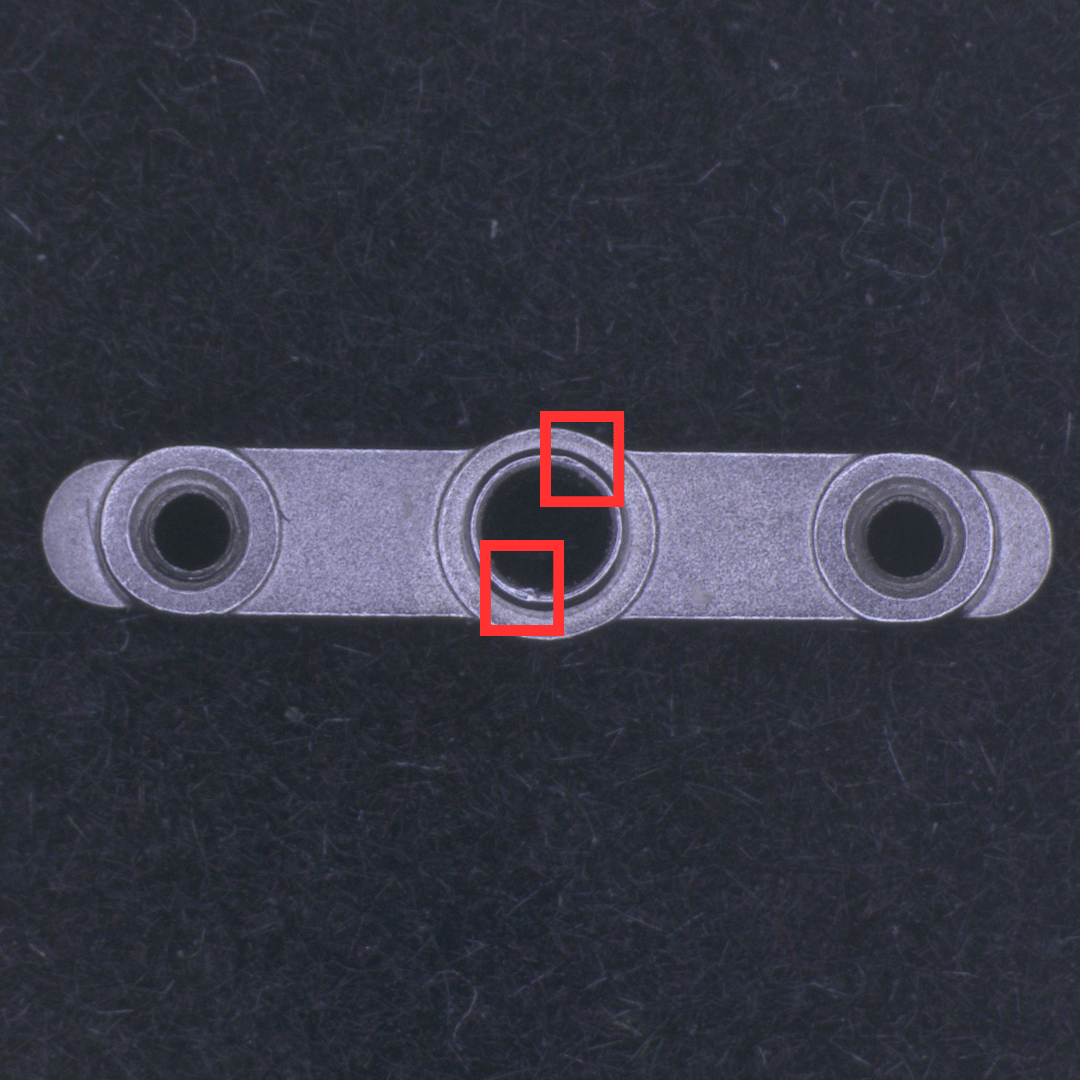

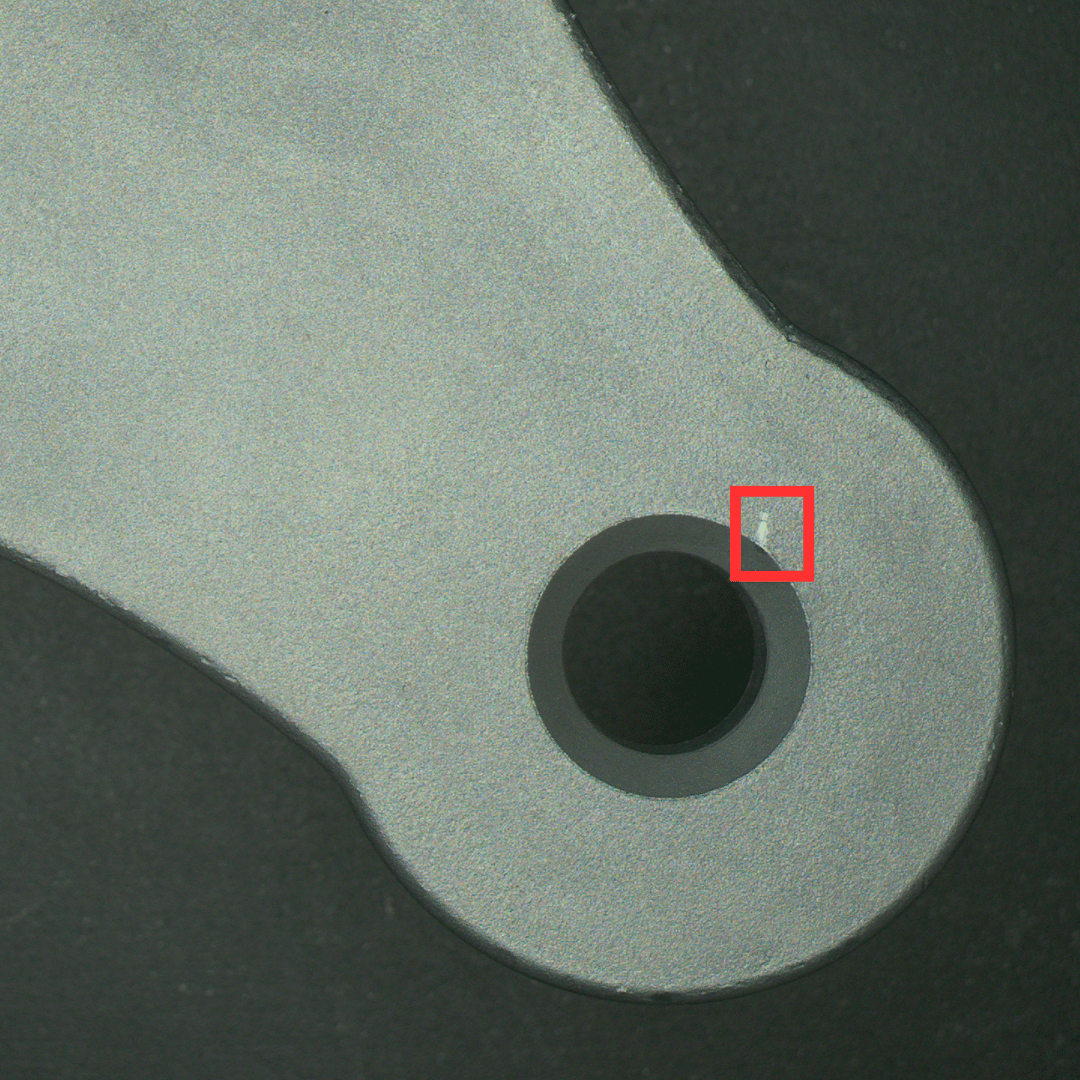

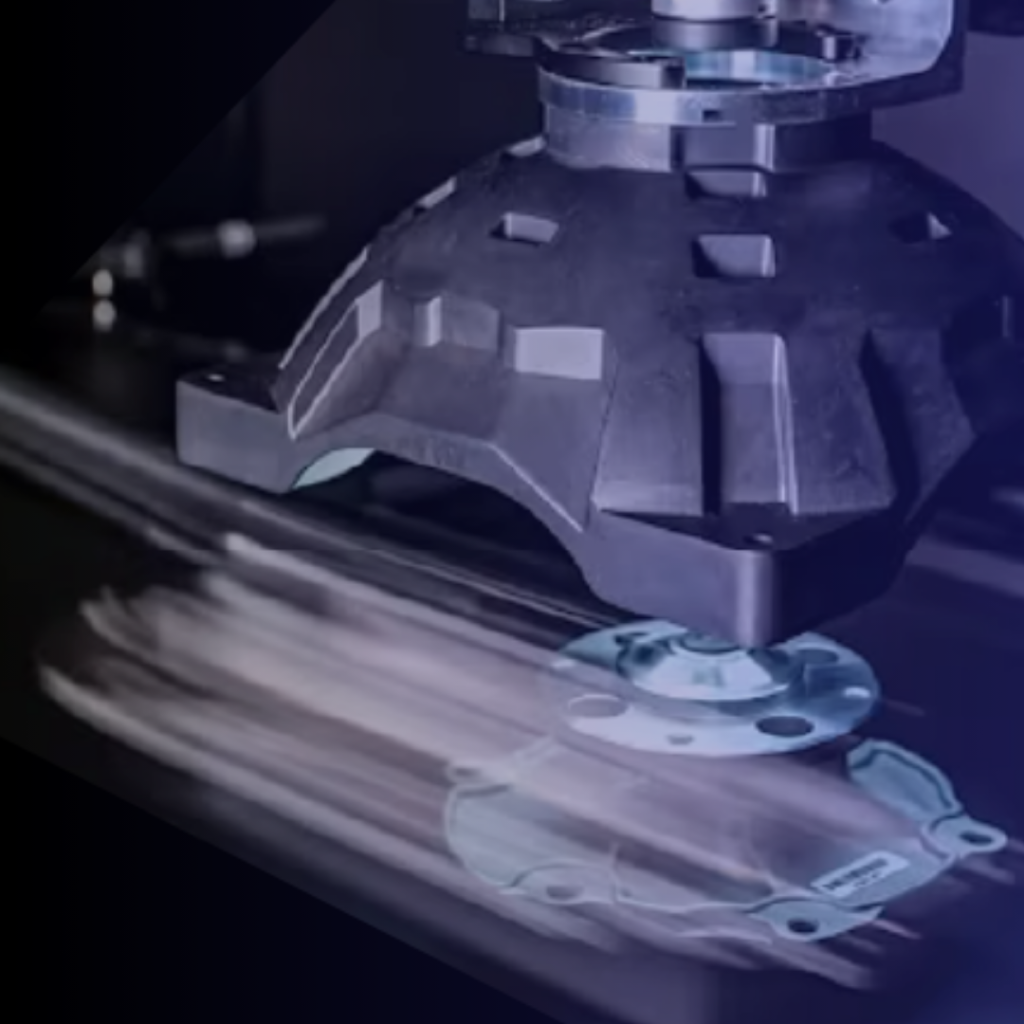

Automotive

Inspect car parts, panels, and assemblies for

surface defects and dimensional accuracy.

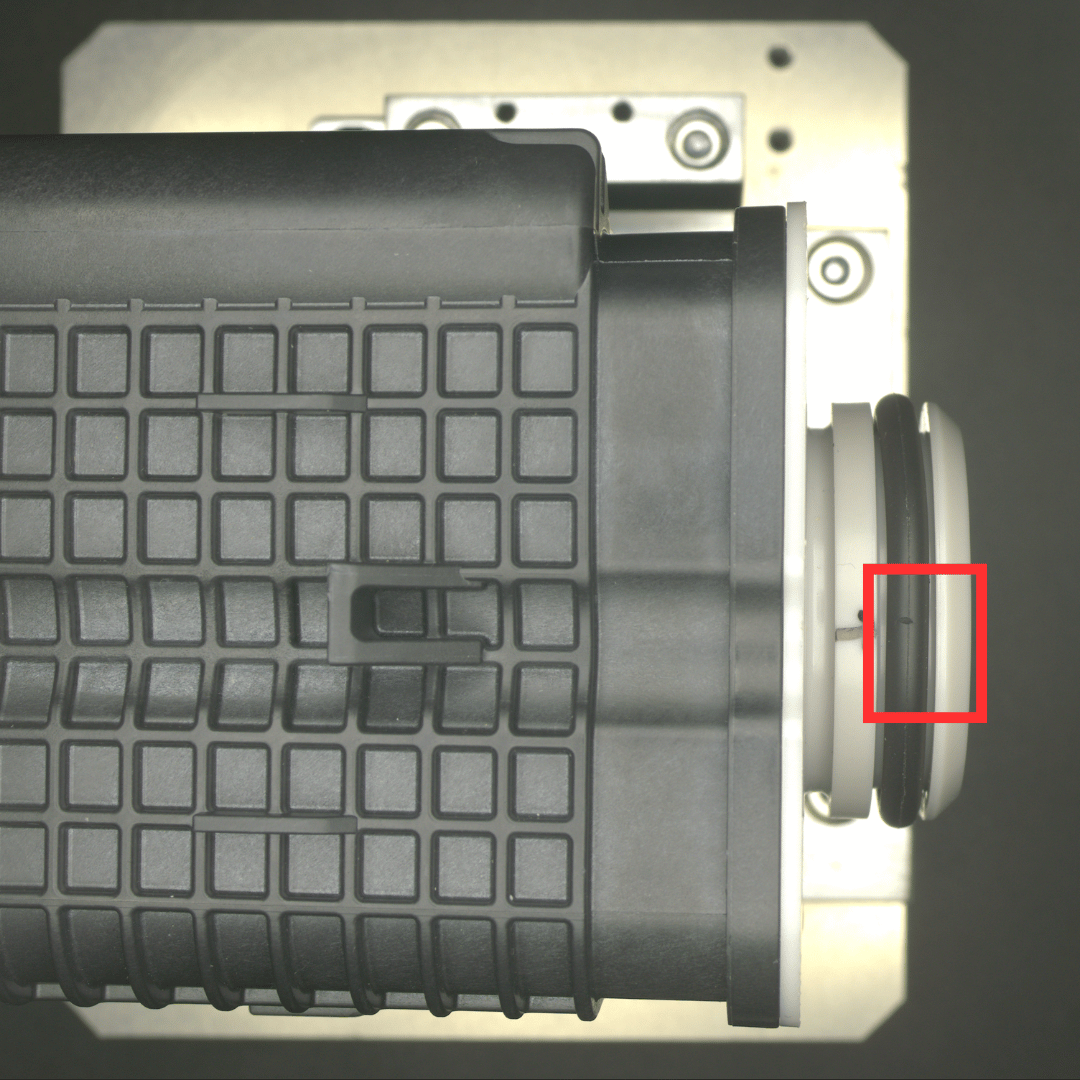

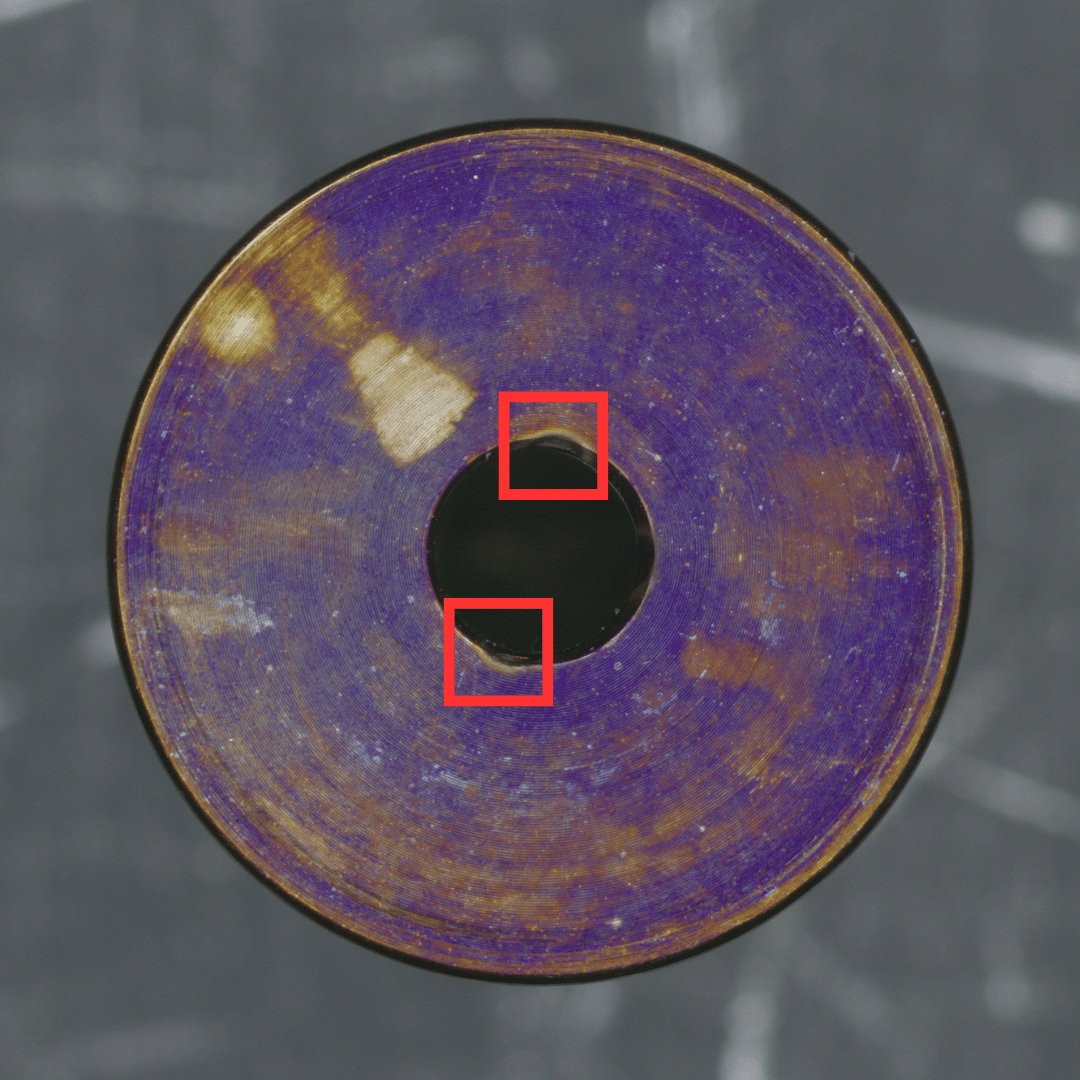

EV Batteries

Inspect battery cells and components for sealing

defects and integrity.

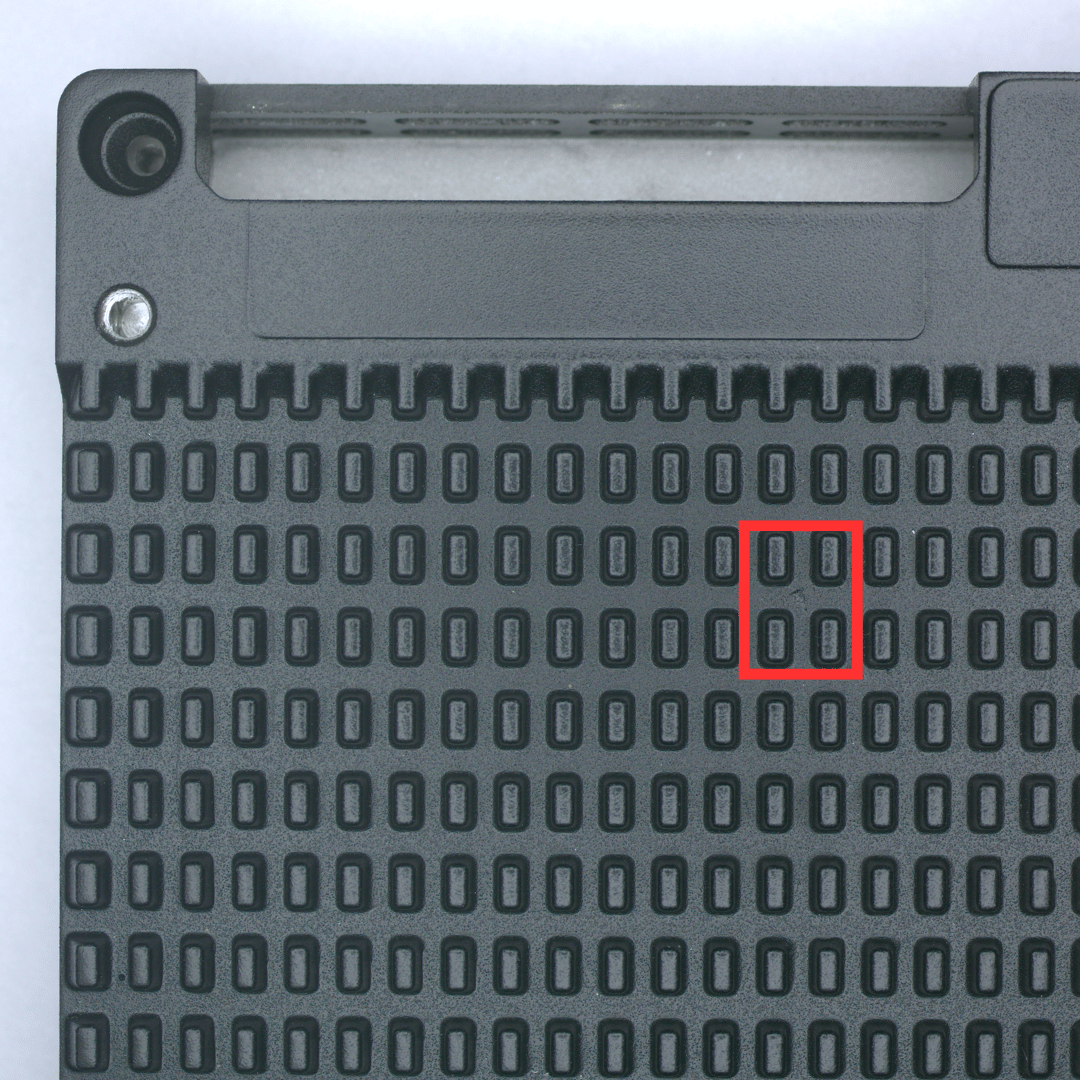

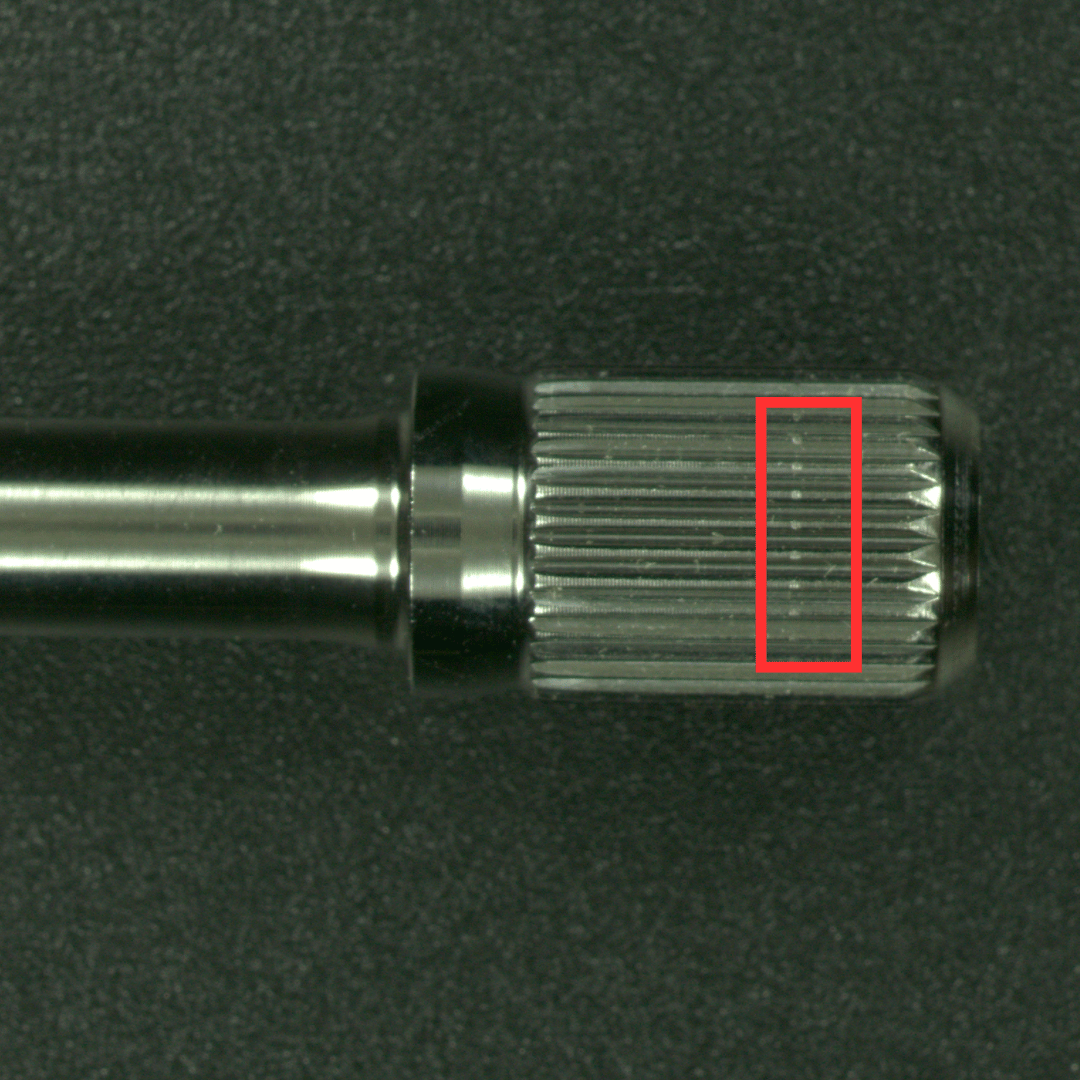

Consumer Electronics

Ensure precise quality control for product

housing, PCBs, and screens.

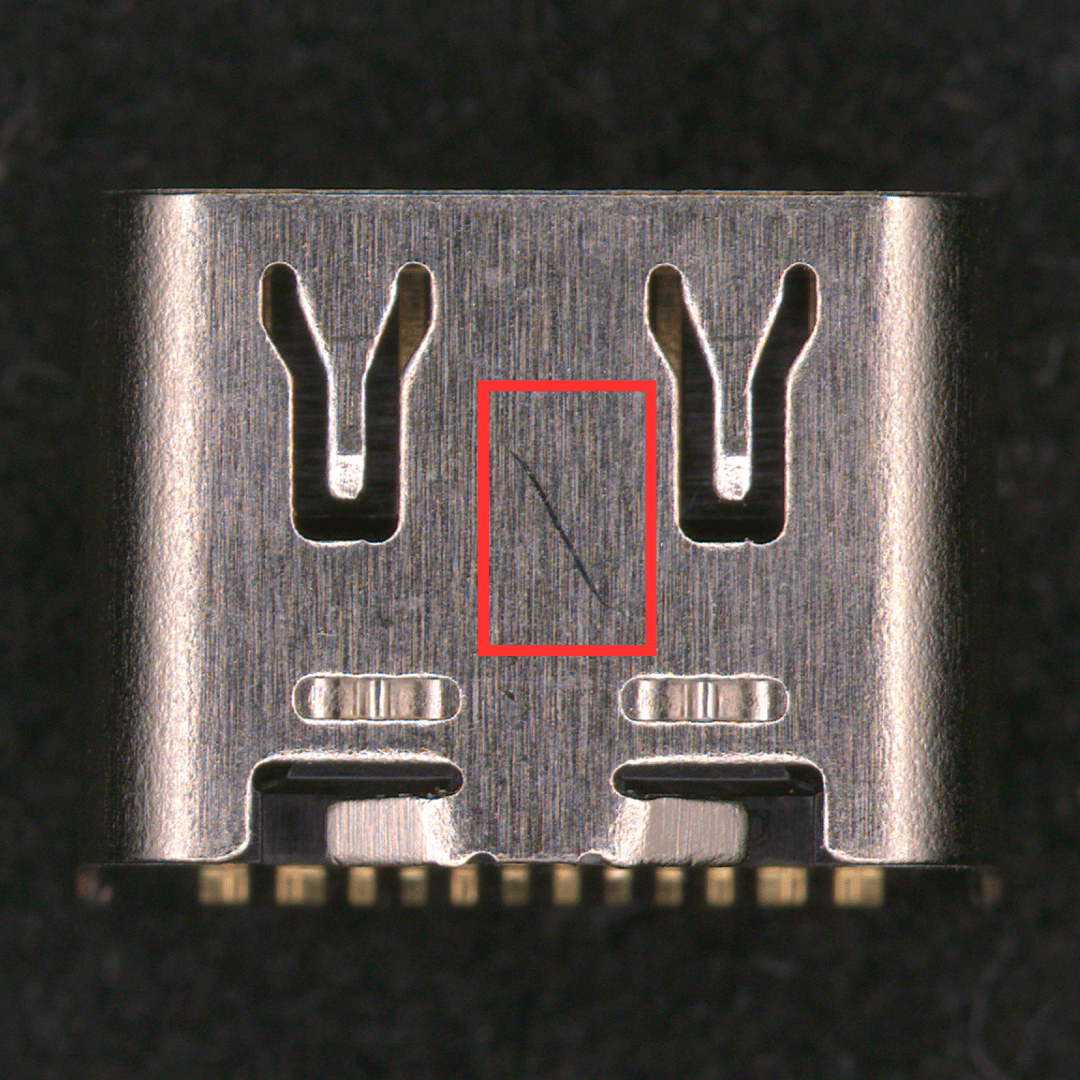

Packaging

Detect surface imperfections in

food & medical packaging

Elevating Quality Across Industries

The speed of deployment was incredible – we were up and running in just 7 days!

Automotive Industry

With FleX, we reduced our scrap rate by 1.3X, making our production more efficient and minimizing defects significantly.

EV Battery Industry

FleX helped us achieve 99.8% accuracy in our inspections, reducing defect escapes by 3X in the first quarter.

Consumer Electronics Industry

By using GenX, we achieved inline inspection with industry-leading accuracy, even for rare defects. The smart labeling and synthetic data generation made AI model training seamless and cost-effective.

Packaging Industry