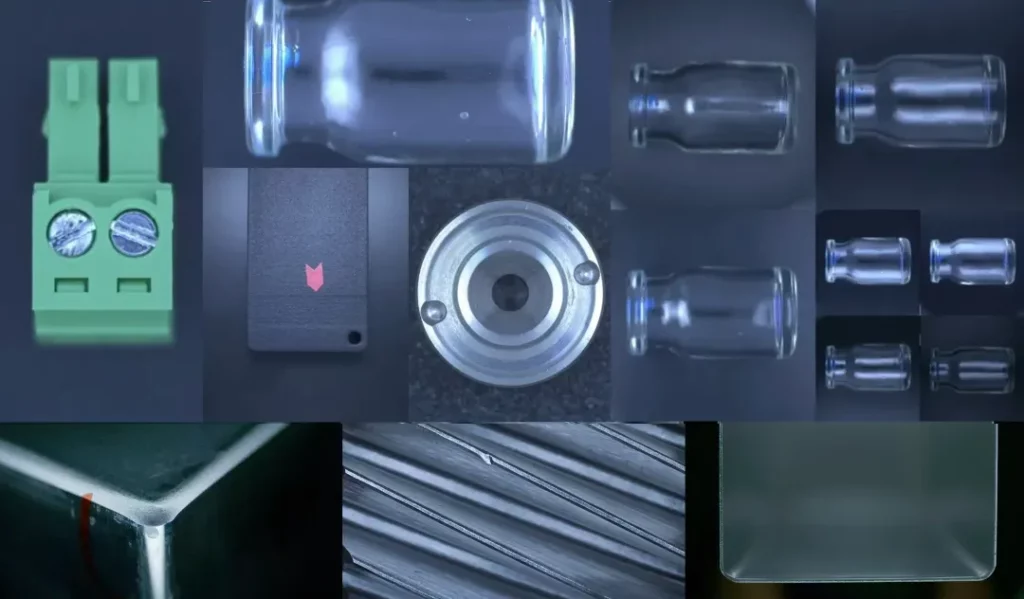

Poor imaging is detrimental to inspection accuracy. Capture optimal images with the OptiX software-defined imaging system

Illuminate and image difficult defects across variable materials

independently controllable light sources

incident angle range

Supports fast experimentation and adaptation to production environments

Achieve rapid inspection times that match production cycle times

meter / sec fly capture

meter / sec fly capture

parts/minute

lighting patterns / second

Requires new bespoke lighting for every application

Software-defined lighting system allows dynamic control over lighting patterns and angles to support variable surfaces and defects

Requires vision expertise to trial multiple hardware to find best lighting option

No vision expertise needed to configure dynamic lighting via software

Lower-power electronics require parts to stop in order to capture images, slowing down cycle time

High-power electronics enable rapid fly capture to image moving parts, matching cycle time