Introduction: Small Parts, Big Volume

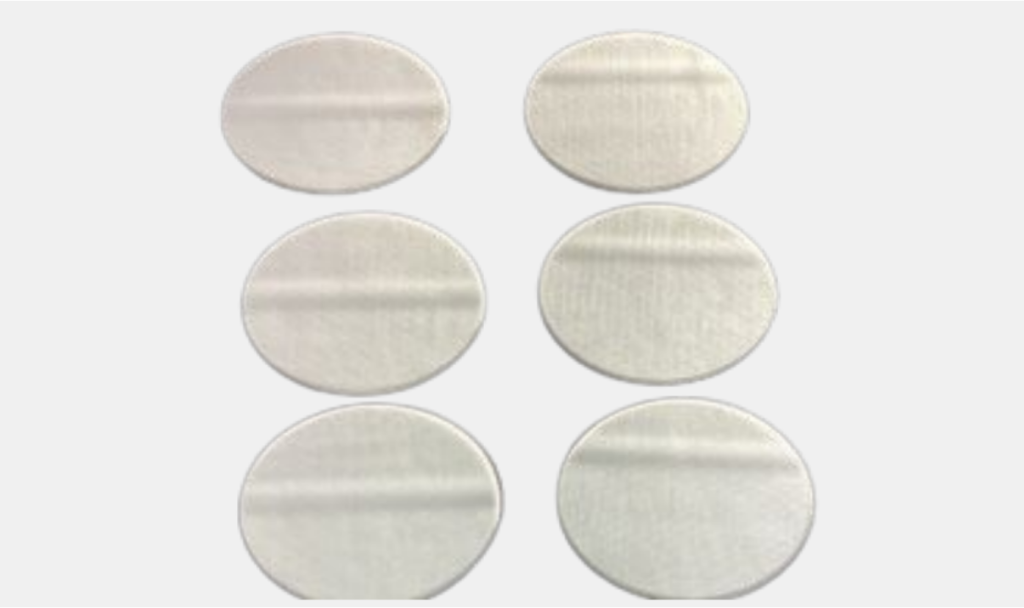

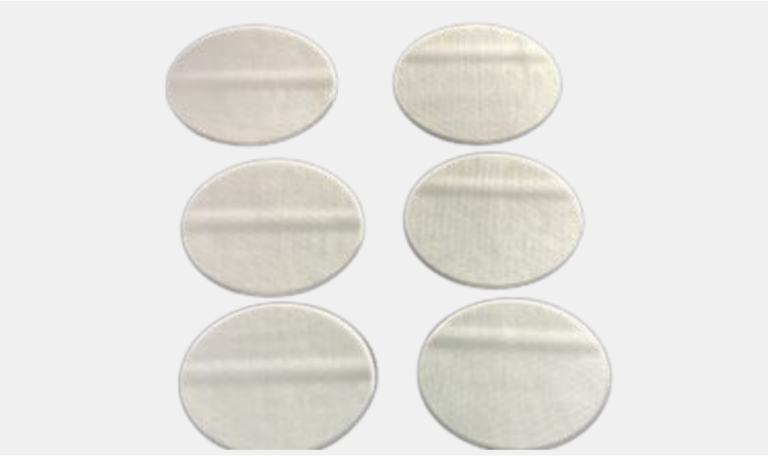

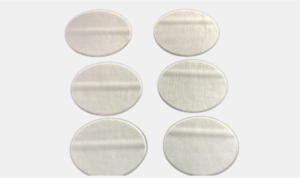

Automotive circular heating films are compact components, often hidden behind mirrors, sensors, or interior surfaces to prevent fogging and freezing. While they are low-cost per unit, they are produced in massive volumes.

The problem? Because they are made of flexible films and adhesives, they are prone to a chaotic range of defects—wrinkles, tears, glue overflow, and foreign fibers. Manual inspection is notoriously inconsistent because these defects can be subtle and the film itself is hard to handle. A functional failure—such as a blocked hole or torn circuit—triggers downstream liabilities and warranty claims that vastly exceed the unit cost of the part itself.

The Challenge: The Flexible Nightmare

The project required inspecting a continuous web of heating films. The defect list was exhaustive, covering issues with the film substrate, the adhesive, and the liner:

- Film Issues: Tears, scratches, curling, edge lifting, and color deviation.

- Adhesive Issues: Glue filaments, white adhesive fibers, overflow, and air bubbles.

- Process Errors: Hole blockage and product overlapping.

Handling this variety on a fast-moving web required a stable, high-precision solution.

Circular heating films present a challenge due to their transparency, flexibility, and adhesive components

The Solution: Roll-to-Roll AI Vision

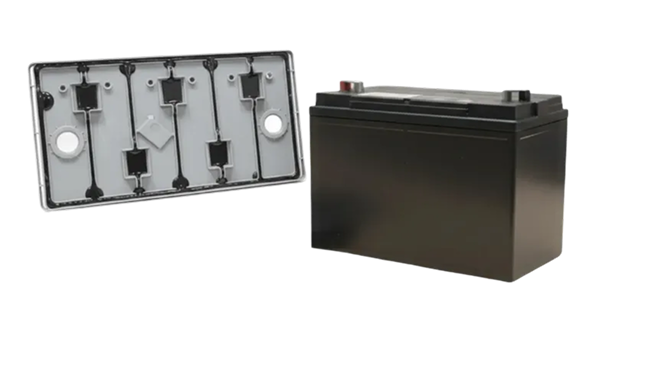

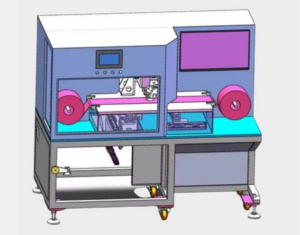

UnitX deployed a specialized Roll-to-Roll AI visual inspection system.

The UnitX system continuously unwinds, flattens, and inspects the film from a supply spool

Process Flow:

- Continuous Feed: The system unwinds the film from a supply spool.

- Flattening: Crucially, the system flattens the film under the UnitX OptiX imaging system to eliminate false positives from natural curling.

- Real-Time Detection: As the web moves, the CorteX AI Central detects defects instantly.

- Automatic Diversion: Any section of the web flagged as NG (No Good) is automatically diverted or marked to prevent it from advancing to the final assembly.

Results: Stability at Speed

The leap from manual oversight to AI-driven automation didn’t just improve the process—it stabilized it. The deployment achieved the following benchmarks:

- 1. Zero Escapes: 0% False Acceptance Rate

Structural compromises, such as blocked holes or micro-tears in the film, are intercepted with 100% reliability.

- 2. Minimal Scrap: ≤ 2% False Rejection Rate

High-speed web inspection is notoriously noisy; slight vibrations and “web flutter” typically trigger a cascade of false alarms. Our AI distinguishes between harmless shadows and genuine structural flaws, ensuring that the high-value material stays on the line instead of in the scrap bin.

- 3. Max Throughput: 1.5-Second Cycle Time.

UnitX system is engineered to synchronize perfectly with high-speed unwinding processes. By analyzing multiple units on the web simultaneously in a 1.5-second burst, it ensures that 100% inspection coverage never becomes a bottleneck for the production velocity.

Defect Gallery

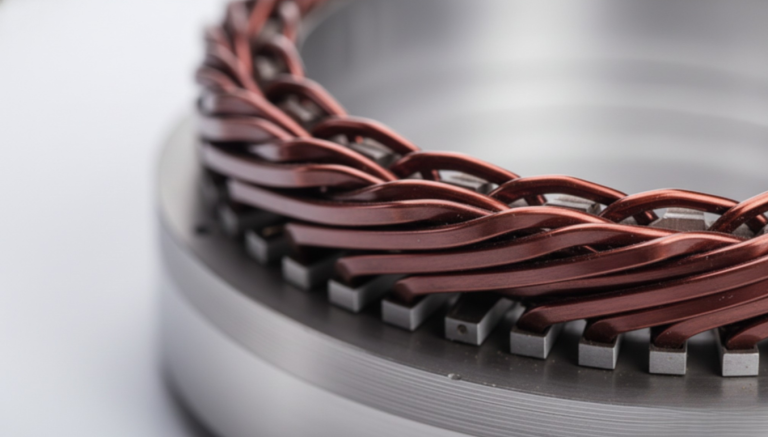

The CorteX AI’s ability to spot white-on-white defects (like adhesive fibers) and shape irregularities is key.

The UnitX system detects complex web defects like overlapping products, glue overflow, and blocked functional holes

Conclusion

Roll-to-roll manufacturing offers speed, but quality control is often the bottleneck. UnitX’s AI inspection removes that bottleneck. By stabilizing the web and using deep learning to interpret complex adhesive and film defects, we allow manufacturers to run their lines at full speed with zero risk of shipping defective heating films.

Need better quality control for your web products?

Contact UnitX to discuss our Roll-to-Roll inspection solutions.