Introduction: The “Curveball” of Battery Inspection

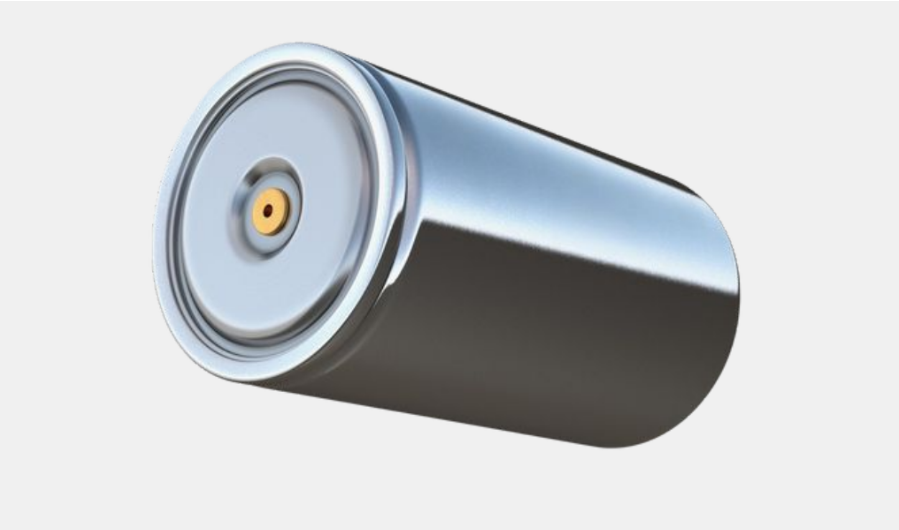

Cylindrical batteries are the workhorses of the energy world. However, their defining feature—their curved, reflective metallic body—is a formidable hurdle for quality control.

Light bounces off the curvature unpredictably, often hiding physical defects like pits, impact marks, and scratches amidst the glare. Traditional rule-based vision systems often struggle here, failing to distinguish between a harmless reflection and a dangerous dent. This forces manufacturers to rely on manual spot checks, which creates traceability gaps and increases the risk of field failures.

But what if you already have cameras on your line, but they just aren’t smart enough? Do you have to replace everything? The answer is NO.

The Challenge: Upgrade Intelligence, Not Just Infrastructure

The goal of this project was to implement a robust vision solution that could detect defects on the full body of cylindrical batteries and output the data directly to the MES (Manufacturing Execution System).

However, there was a catch: The client needed to renovate an existing vision system. They didn’t necessarily need new cameras; they needed a better “brain” to interpret the images. The solution had to be compatible with 3rd-party imaging hardware while delivering next-generation detection capabilities.

Defect Targets:

- Surface Depth Issues: Pits and impact marks (hard to see on 2D images).

- Surface Quality: Contamination and scratches.

The Solution: A “CorteX-Only” Retrofit

UnitX delivered a flexible CorteX-only solution. Instead of replacing the entire optical stack, we integrated our powerful AI computing units with the customer’s compatible 3rd-party imaging hardware.

Key Technical Enablers:

- 2.5D Imaging Support: To detect “pits” and “impact marks” that have depth but no color contrast, the system supports 2.5D imaging. This technique (likely utilizing photometric stereo principles) allows the AI to see the texture and topography of the battery surface, not just the color.

- QR Code Integration: The system supports QR code reading at the 4th station, ensuring that every detected defect is linked to a specific battery ID in the MES for full traceability.

High Speed, Deep Insights

By injecting UnitX AI into the existing production line, the system achieved performance metrics that legacy algorithms could not touch.

- Uncompromising Safety: Achieved a 0% false acceptance rate standard for structural defects, ensuring no units with pits or impact marks advance to assembly.

- High-Velocity Throughput at 180 PPM: Full-body surface inspection of three batteries per second, matching the pace of the world’s fastest production lines.

- Superior Yield Protection : ≤ 5% false rejection rate distinguishes real defects from harmless surface variations, minimizing unnecessary scrap.

- Thermal Risk Mitigation: By catching physical compromises at the source, UnitX effectively prevents downstream thermal issues in final battery packs.

Conclusion

This case study proves that you don’t always need to build a new factory to get smart manufacturing results. By upgrading your existing vision lines with UnitX CorteX compute units, you can unlock advanced capabilities like 2.5D inspection and AI defect classification.

Have existing cameras that aren’t doing the job?

Contact UnitX to see if a “CorteX-Only” retrofit is the right solution for your line.