Introduction: The Pressure is On

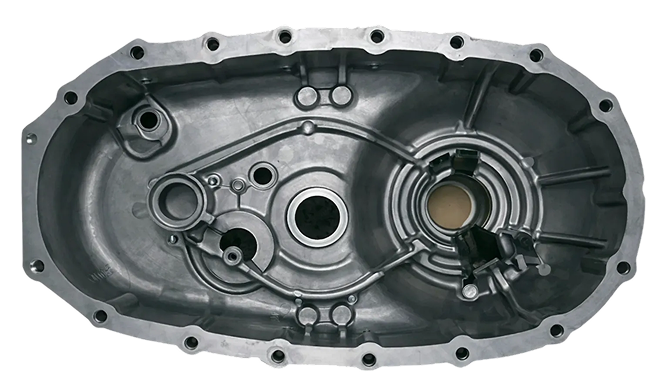

In the automotive industry, the Pump Housing is a component that lives under stress. Whether for oil, water, or fuel, these housings must withstand high pressures and maintain perfect seals.

Defects that might look minor on the surface—like porosity (tiny air pockets in the metal), material loss, or peeling—can become stress concentration points. Under operating pressure, these flaws can cause the housing to crack, leading to catastrophic leaks and engine failure.

Traditionally, inspecting these complex, machined metal parts (approx. 60x60x70mm) was a manual process. However, manual inspection struggles to spot “incomplete machining” or subtle “color variations” consistently across thousands of shiny, complex 3D parts.

The Challenge: Complex Defects on 3D Geometry

The goal was to replace manual labor with a fully automated, AI-driven system. The inspection requirements were extensive, covering both casting and machining flaws:

- Surface Flaws: Scratches, pits, dents, and color variations.

- Material Integrity: Porosity (a critical casting defect) and peeling.

- Machining Errors: Material loss and incomplete machining.

Crucially, the client required a system with Remote Update Modules, ensuring that as new defect types appeared or product designs changed, the AI-driven system could be updated without a site visit.

The complex geometry of automotive pump housings hides defects that can lead to pressure failure

The Solution: A 4-Station Servo Conveyor Line

To ensure comprehensive 360-degree coverage, UnitX implemented a multi-stage inspection line integrated with a high-precision servo conveyor. By advancing the part through four distinct inspection stations, the system meticulously captures every angle and complex surface of the 3D geometry, leaving no room for ‘blind spots”.

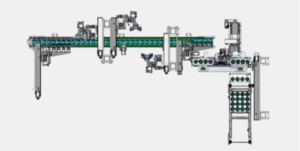

UnitX’s 4-station inspection line, featuring automated diverting for OK and NG parts

Intelligent Sorting Logic:

- Real-Time Analysis: As the part moves, the UnitX CorteX Edge analyzes images instantly.

- Automated Diverting:

- OK Parts: Automatically directed to the pallet for shipping.

- NG (No Good) Parts: Instantly diverted for rework or scrap.

Hardware Power:

- Imaging: 4x UnitX OptiX systems provide comprehensive coverage of the housing’s multiple faces.

- Compute: A dedicated CorteX AI Central and Inspection Cell handle the heavy lifting of processing millimeter-scale defects in real-time.

Results: Achieving Zero-Tolerance in Automotive Quality Assurance

The UnitX deployment sets a new standard for reliability, combining high-speed processing with an uncompromising stance on safety.

- Uncompromising Safety: We’ve achieved a 0% False Acceptance Rate for safety-critical defects. By providing total containment for porosity and micro-cracks, the system ensures “zero-leak” reliability, shielding manufacturers from the liabilities of catastrophic part failure.

- Precision-Balanced Yield: Quality shouldn’t come at the cost of high scrap rates. With an overall False Acceptance of ≤ 0.5% for cosmetic flaws and a False Rejection Rate of ≤ 5%, the AI-driven system accurately differentiates between true defects and harmless variations to maximize ROI.

- Synchronized Throughput: Eliminate production bottlenecks. The system performs a comprehensive 3D analysis of complex geometries within a 5-second cycle time, allowing for 100% inspection coverage without slowing down high-volume production lines.

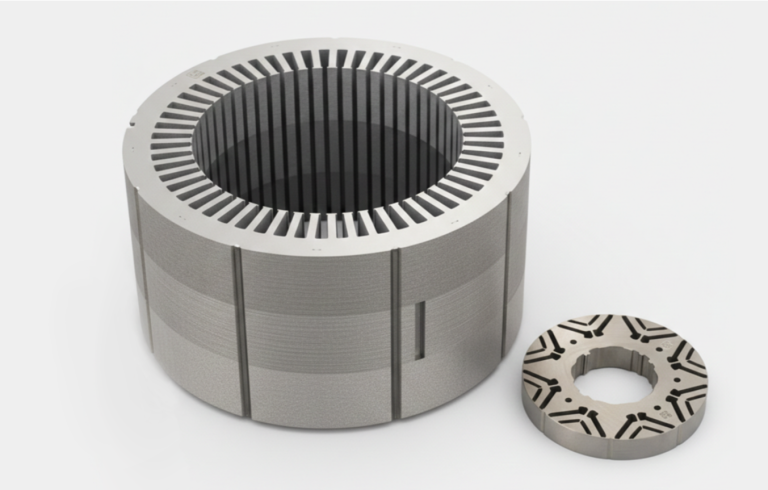

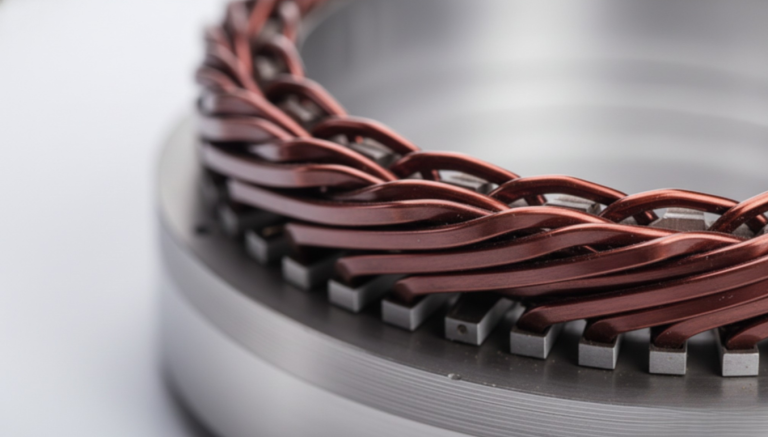

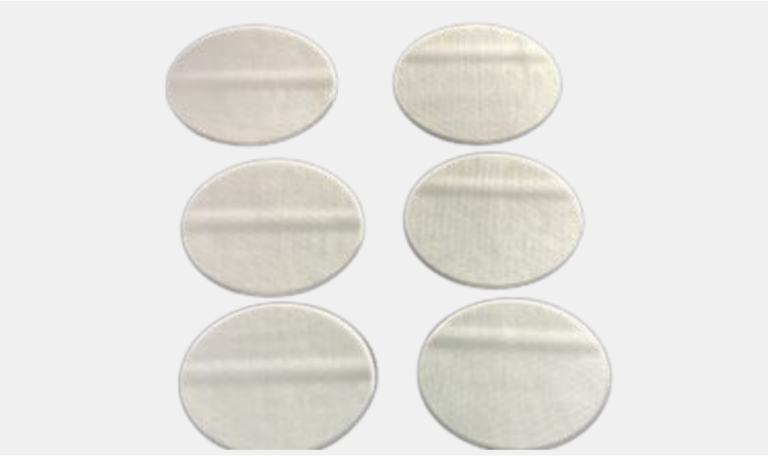

Defect Gallery

The UnitX AI excels at distinguishing between the normal texture of machined metal and actual defects.

The system identifies complex issues like porosity (casting voids) and incomplete machining processes

Conclusion

For automotive components, reliability is non-negotiable. This case study demonstrates how UnitX transforms the inspection of complex metal parts—moving from subjective manual checks to objective, AI-driven data. With the added benefit of remote updates, the system is future-proofed for the long haul.

Need to automate inspection for complex metal parts?

Contact UnitX to discuss our multi-station solutions.