Introduction: Efficiency Starts at the Surface

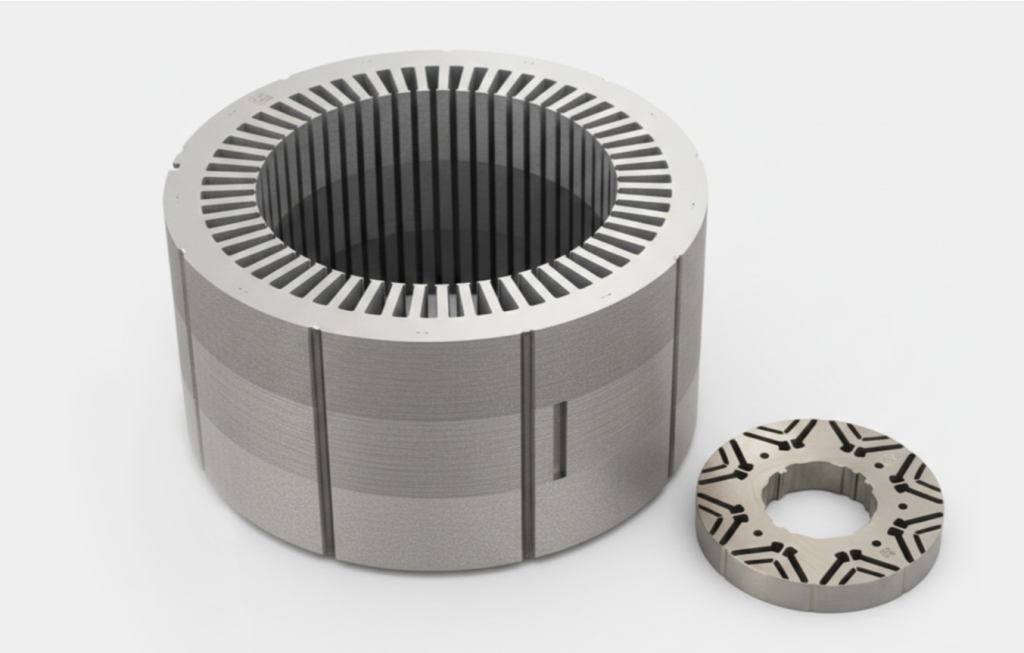

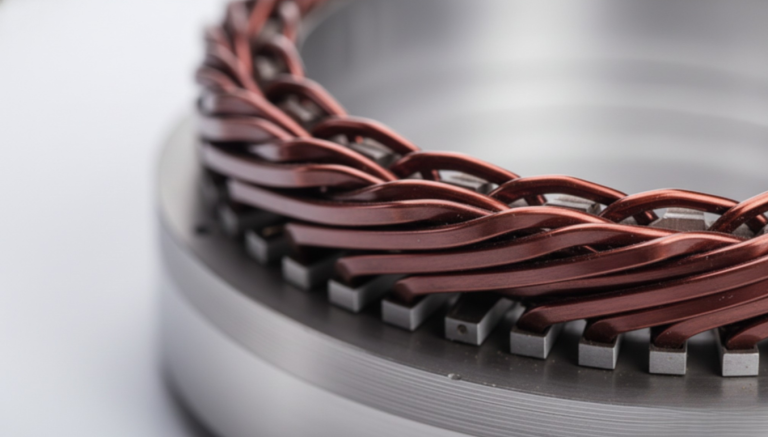

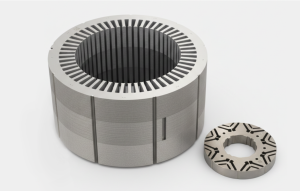

In the automotive powertrain, the Stator and Rotor are the dynamic duo that generates movement. Their efficiency dictates the vehicle’s performance. However, seemingly minor surface defects—like rust, scratches, or contamination on the end faces—can have major consequences. They can increase vibration, reduce motor efficiency, generate excess heat, and lead to premature failure.

For years, manufacturers relied on manual visual checks. But manual inspection varies from person to person and shifts with fatigue. As production volumes ramp up, this manual approach creates a bottleneck, increases rework costs, and leaves gaps in quality traceability.

The Challenge: Speed, Variety, and Precision

The project goal was to upgrade from manual checks to a fully Automated Vision Inspection system. The requirements were stringent:

- Dual Component Handling: The system needed to inspect both Stators and Rotors.

- Comprehensive Coverage: It had to inspect the top and bottom end faces of every unit.

- Flexibility: The line produces 4 different SKUs. The system needed to automatically recognize the part number and route it correctly without manual intervention.

- Traceability: Every result had to be linked to the MES (Manufacturing Execution System) for long-term tracking.

Surface defects on stators and rotors (like rust or dents) can compromise motor efficiency

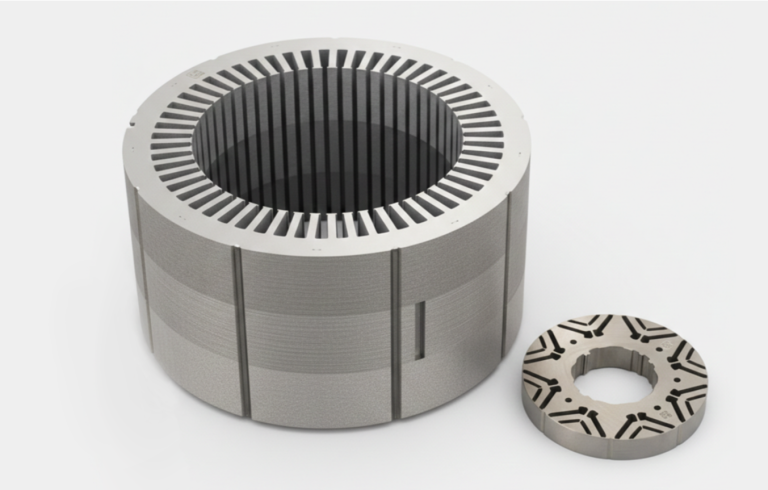

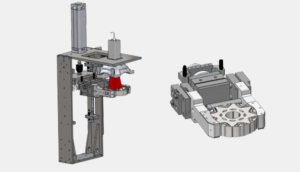

The Solution: A Dual-Station Vision Cell

UnitX’s dual-station cell utilizes multi-angle OptiX exposures to detect sub-millimeter defects

How it Works:

- Full Rotation: The part is rotated during inspection to ensure 360-degree coverage of the circular faces.

- Multi-Angle Exposure:Utilizing UnitX OptiX, the system captures images under different lighting angles to reveal depth-based defects like dents vs. surface-level contamination.

- Intelligent Routing: The system automatically identifies which of the 4 SKUs is on the line and applies the correct AI model.

Results: Sub-Millimeter Precision

UnitX AI inspection solution replaced subjective manual inspections with a data-driven standard that identifies flaws invisible to the naked eye.

- 0.1 mm Defect Sensitivity: Capable of spotting scratches, dents, or occlusions as fine as a human hair—ensuring microscopic imperfections never reach assembly.

- ≤0.5% False Rejection Rate: High-fidelity discrimination that protects your yield by eliminating “pseudo-defects” and unnecessary scrap.

- 0% Escape Rate: Total field reliability. If a functional defect exists, the system captures it—guaranteeing zero False Acceptances.

- < 5s Cycle Time: High-velocity rotor inspection that maintains 100% coverage without slowing down the production heartbeat.

- ≥ 85% OEE: Industrial-grade stability with an equipment fault rate of < 5%, keeping your line optimized and available

Defect Visualization

CorteX AI’s ability to “see” defects is highlighted below. Note how it distinguishes between “Densnap-feature dents” (structural) and simple “Contamination” (cleaning issue).

The AI accurately segments defects ranging from contamination to structural dents

Conclusion

In modern automotive manufacturing, “consistent quality” is just as important as “high quality.” By automating the inspection of Stators and Rotors, UnitX helps manufacturers achieve both. With 0.1mm precision and auto-SKU recognition, our system ensures that every motor built is as efficient and reliable as designed.

Ready to automate your motor assembly line?

Contact UnitX to discuss our high-speed inspection cells.