Introduction: The Heart of the Electric Vehicle

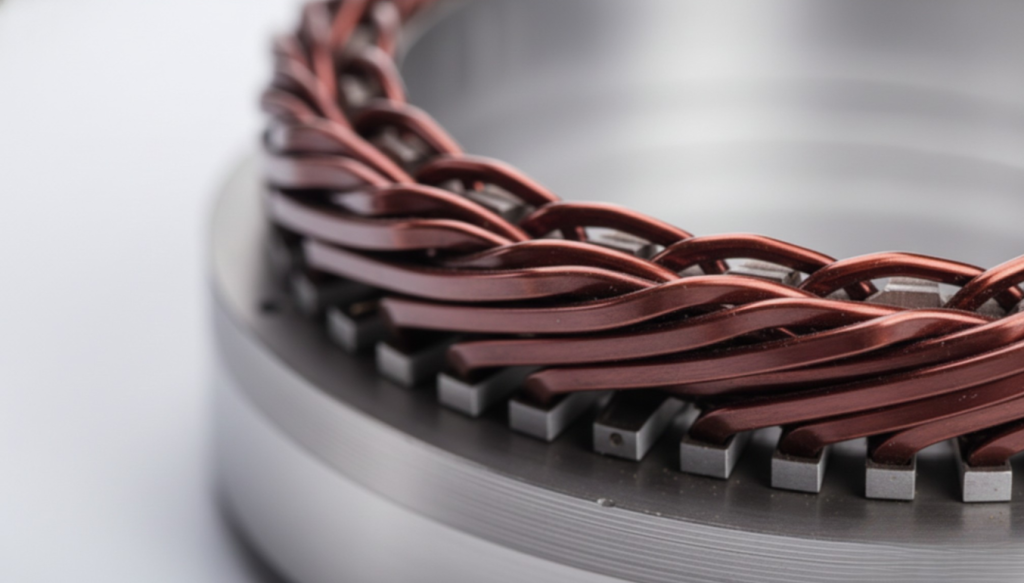

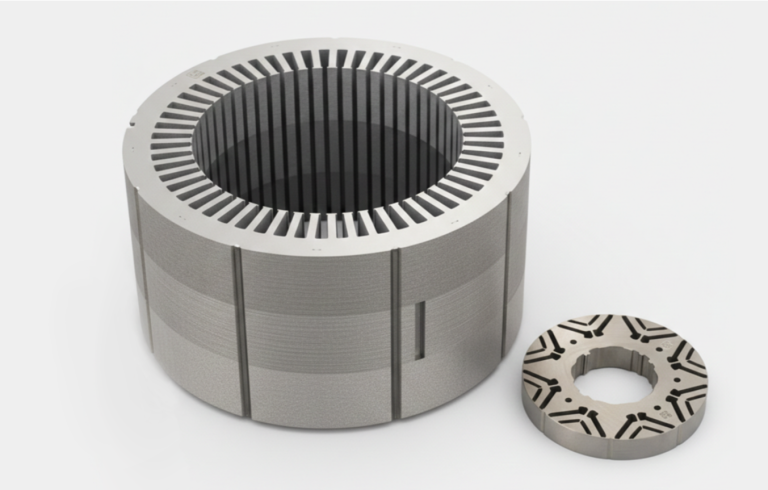

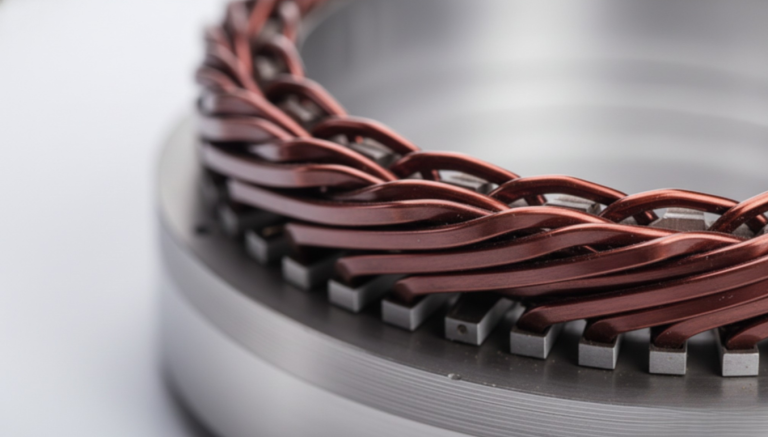

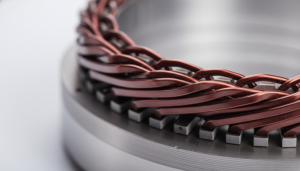

The Electric Stator is the stationary part of an electric motor, and in modern EVs, “Hairpin” stator technology is the gold standard for efficiency. However, manufacturing them is an intricate process. Hundreds of copper hairpins must be inserted, twisted, and welded with absolute precision.

Defects here are catastrophic. A “missing weld” means an open circuit. “Enamel damage” means a short circuit. “Core delamination” destroys efficiency. Traditional manual spot checks or simple 2D cameras struggle with the dense, reflective geometry of the copper pins and the need for rapid model changeovers.

For our client, the goal was to eliminate secondary manual checks entirely and prevent any defective stator from reaching downstream electrical testing.

The Challenge: 8 Critical Defects on a Complex Curve

The project required a high-accuracy AI solution to inspect 8 specific critical defects on the stator.

The complexity lies in the density of the features. The inspection system must differentiate between:

- Weld Issues: Missing welds, weld shape issues, and “2-ball” (double bead) defects.

- Insulation Issues: Enamel damage and liner tears (the paper separating the coils).

- Structural Issues: Core delamination and burrs.

All of this had to be done on a round, rotating part with highly reflective copper surfaces.

Hairpin stators feature complex copper winding geometry that is difficult to inspect manually

The Solution: 360° Sensor Fusion

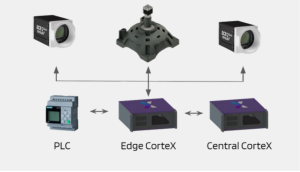

UnitX delivered a 3-camera integration designed for complete 360° multi-angle coverage.

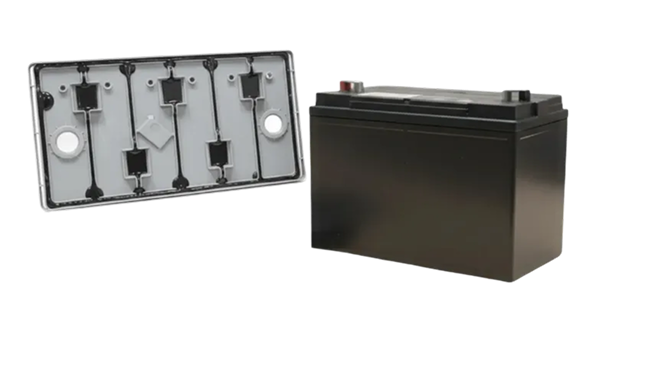

The UnitX system integrates OptiX visual system with rotary tables and PLCs for seamless inline inspection

System Architecture:

-

- 360° OptiX Imaging: OptiX synchronizes a three-camera array with the rotary table, capturing every weld crown and insulation sheet to provide a comprehensive surface analysis.

- CorteX AI Intelligence: CorteX fuses multi-camera streams and identifies structural flaws that traditional manual inspection systems miss.

- Precision Traceability:: The system integrates directly with the PLC and MES, enabling real-time traceability. If a specific pin is bad, the system knows exactly which one it is.

Results: 100% Validation Accuracy

The system’s performance during validation proved that AI is the superior choice for EV motor inspection.

1. Flawless Detection Accuracy

- Result: 100% detection accuracy during validation across all 8 defect types.

- The AI successfully learned the difference between a healthy weld bead and complex defects like “2-balls” or “burrs.”

2. High Reliability

- False Acceptance Rate: ≤ 1%.

- False Rejection Rate: ≤ 5%.

- By keeping false accepts under 1%, the client significantly reduced the risk of passing a bad motor to the electrical test stage (where failures are much more expensive to fix).

3. Efficient Cycle Time

- Cycle Time: < 40 seconds.

- Considering the stator must be rotated and hundreds of pins inspected, this cycle time supports the throughput requirements of high-volume EV production lines.

Defect Prediction

The AI’s ability to segment and classify defects is shown below. Note the precision in identifying “Enamel Damage” on the thin copper wire and “Liner Tears” on the insulation paper.

UnitX AI overlays show precise detection of enamel damage, liner tears, and weld defects

Conclusion

As the EV market surges, the quality of the electric motor is a key differentiator. UnitX’s Stator Inspection solution offers the sub-0.1% miss rates and real-time traceability that automotive OEMs demand. We turn the complex geometry of a hairpin stator into a solved quality control problem.

Building EV motors?

Contact UnitX to ensure your stators are 100% defect-free.