Introduction: The First Impression

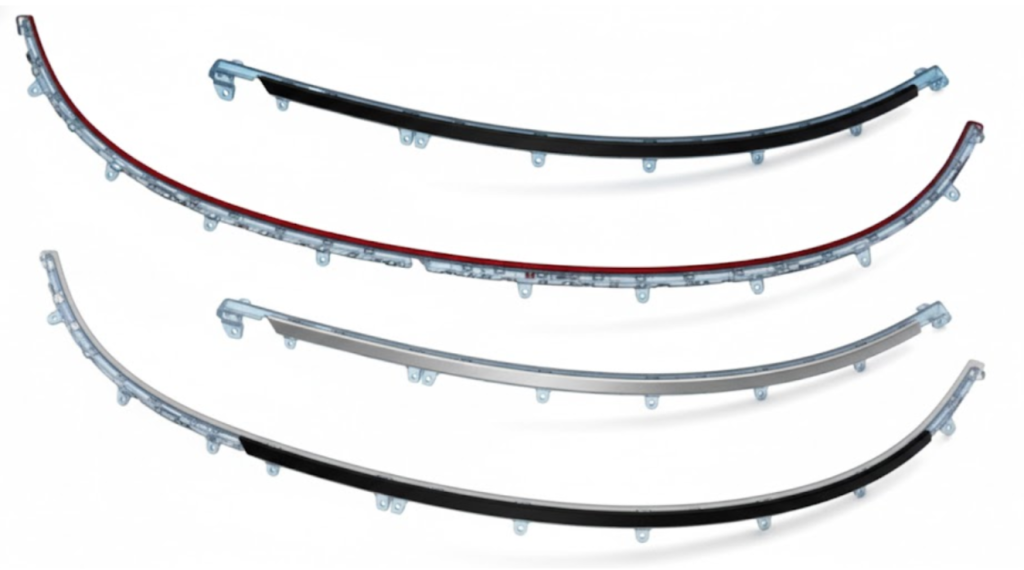

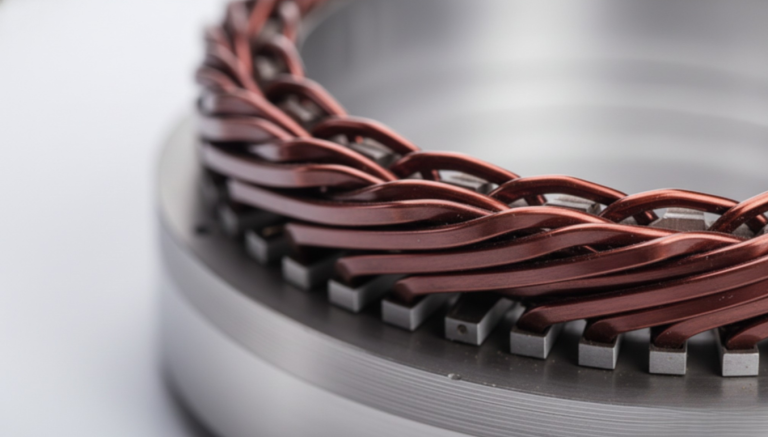

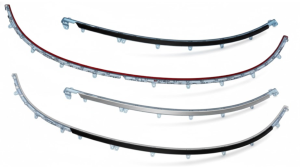

When a customer opens a new car door, the interior trim is one of the first things they see and touch. It is a primary aesthetic feature. A scratch, a “hairline” crack, or a black spot on a silver trim isn’t a safety hazard—but it kills the brand’s reputation for quality.

For suppliers, OEMs mandate “defect-free” deliveries. Traditionally, achieving this level of precision required extensive manual inspection teams conducting exhaustive visual assessments under high-intensity lighting. This process is subjective, expensive, and slow. Our client was spending too much time (20-25 seconds per part) and money on manual checks.

The Challenge: Speed and Subjectivity

The goal was to automate the inspection of Automotive Door Trims to save labor costs and lock in consistent quality standards.

The challenges were distinct:

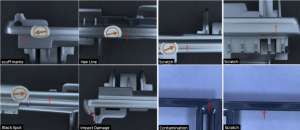

- Complex Defects: The system had to spot subtle aesthetic issues like “sandpaper marks,” “hairlines,” and “discolored spots” on both black and silver surfaces.

- Dual-Sided: Inspection was needed on both Side A (visible) and Side B.

- Speed: The manual cycle time of 20-25s was a bottleneck.

Automotive door trims require flawless aesthetic quality to meet OEM standards

The Solution: A Turnkey Robotic Cell

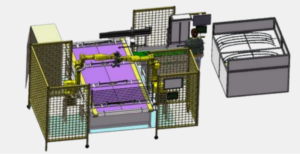

UnitX delivered a turnkey “Load–Inspect–Sort” cell that completely automates the workflow.

A six-axis robot manipulates the OptiX system for comprehensive inspection in a guarded bay

How it Works:

- Robotic Precision: A six-axis robot moves the UnitX OptiX imaging system over the part (or moves the part under the camera), enabling complex scan paths that cover every curve of the trim.

- AI Analysis: The CorteX AI analyzes high-resolution images in real-time.

- Automated Sorting:

- OK Panels: Automatically placed on the shipping pallet.

- NG Parts: Diverted to a reject bin.

- Data Logging: Full data logging ensures traceability for every shipped part.

Results: Faster, Cheaper, Better

The transition from manual to AI inspection delivered drastic operational improvements.

1. Cycle Time Slashed

Before: 20s–25s (Manual).

After: 8s–14s (AI Automation).

The system essentially doubled the throughput capability of the inspection station.

2.50%+ Labor Cost Reduction

Impact: Saved 50%+ in labor costs.

Headcount: Reduced the inspection team from 4 people to 2 people.

This direct ROI makes the system pay for itself rapidly while freeing up staff for higher-value tasks.

3. Reliable Aesthetic Quality

- False Acceptance Rate: 0.5%.

- False Rejection Rate: ≤ 5%.

- The AI successfully detects difficult defects like scuff marks, hairlines, and black spots on both black and silver finishes.

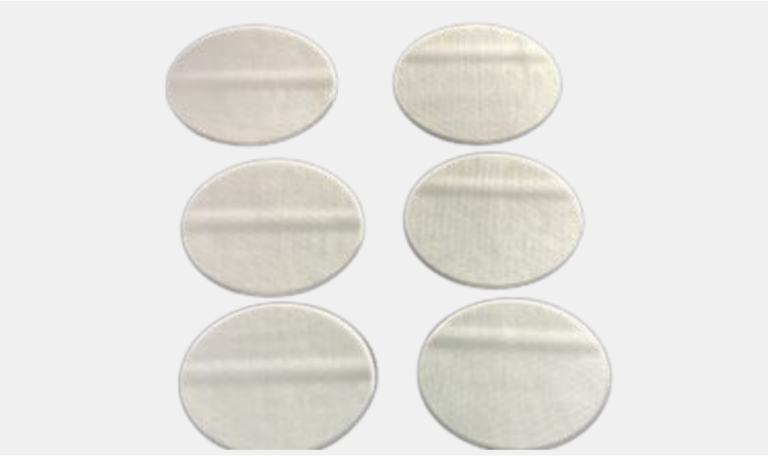

The AI detects subtle aesthetic flaws like hairlines and scuff marks that undermine perceived quality

Conclusion

In the automotive interior market, perception is reality. UnitX helps suppliers protect that perception while drastically cutting costs. By reducing cycle time by ~50% and labor by 50%, our robotic inspection cell turns a cost center into a competitive advantage.

Want to cut your inspection cycle time in half?

Contact UnitX to automate your interior trim lines.