Introduction: The Foundation of Autonomous Driving

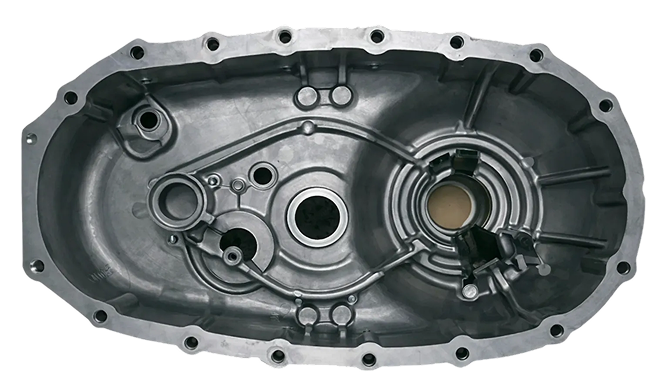

As vehicles move toward higher levels of autonomy (ADAS), the automotive camera module becomes one of the most critical sensors on the car. The Camera Base (Housing) is the chassis of this sensor—it holds the lens, optics, and PCB in precise alignment.

If this housing has a surface flaw, it can lead to module instability, improper focus, or seal failures. A “rough weld” might cause a leak; “damaged threads” might prevent proper assembly. Ensuring these bases are flawless is essential for the reliability of the entire vision system.

However, inspecting a camera base is geometrically complex. It’s not a flat sheet; it’s a 3D component with internal bores, threaded holes, rivet points, and multiple sidewalls. A single camera simply cannot see it all.

The Challenge: Internal Threads and Outer Walls

The project goal was comprehensive: Inspect all critical faces of the camera base.

This included a laundry list of hard-to-reach areas:

- Internal Features: The internal threaded bore and bore edges.

- External Surfaces: Four outer sidewalls and the coded side.

- Assembly Points: Rivet-pressed surfaces and weld surfaces.

The defect list was equally demanding, requiring the detection of material underfill, blisters, peeling, and specifically thread damage (stripped threads/burrs), which are notoriously difficult to capture with standard lighting.

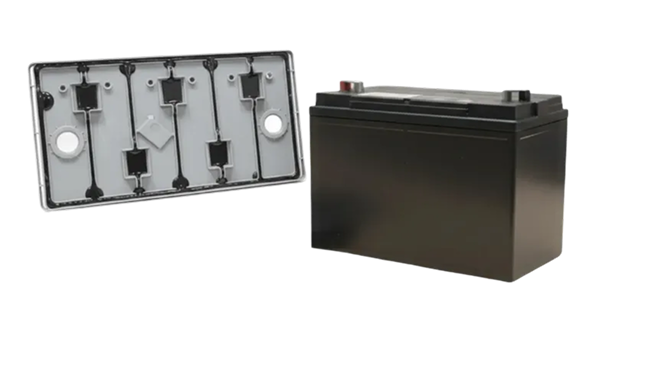

The camera base requires multi-face inspection, including internal threads and four outer sidewalls

The Solution: A 6-Camera Integrated Station

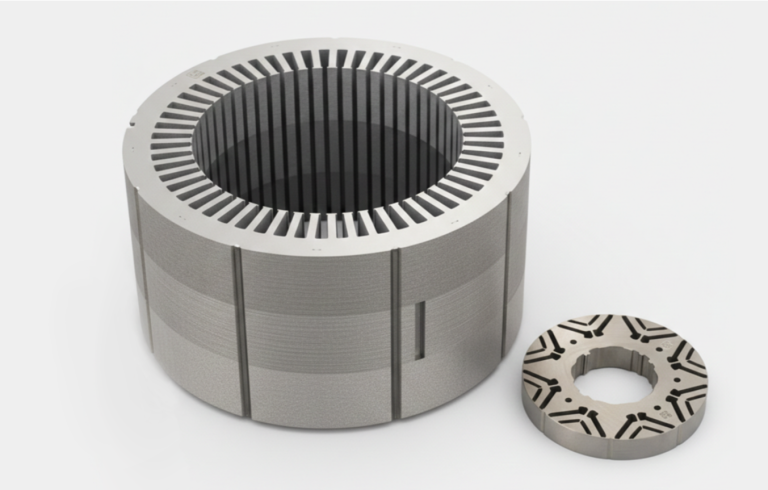

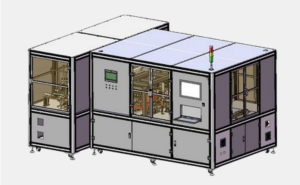

To capture every angle of this complex object, UnitX deployed a heavy-duty Automated Surface-Inspection System.

UnitX’s inspection station integrates 6 cameras to cover every critical angle of the camera housing

System Configuration:

- Multi-View Imaging: The system features 6 integrated UnitX OptiX vision systems distributed across dedicated stations. This allows for simultaneous inspection of the top, sides, and internal bores.

- AI Processing: A UnitX CorteX unit processes the feed from all 6 cameras, correlating defects across different views to ensure no double-counting or missed flaws.

- Data Integration: Inspection results are communicated directly to the equipment layer, allowing for immediate process feedback.

Results: Speed Meets Precision

The system successfully automated what is typically a slow, manual rotation inspection process.

1. High-Speed Multi-Face Inspection

- Cycle Time: 2 seconds per piece.

- In just two seconds, the system captures and analyzes images from 6 different cameras, inspecting threads, welds, and walls. This throughput matches high-volume automotive production lines.

2. Detecting the “Hard-to-See”

- False Acceptance Rate: 0.5%.

- The system reliably detects defects that often escape human notice, such as internal thread damage and hole opening damage.

3. Reliable Quality Control

- False Rejection Rate: ≤ 5%.

- By maintaining a low false rejection rate, the system ensures that good parts aren’t scrapped due to minor, non-functional surface variations (like harmless water stains vs. actual corrosion).

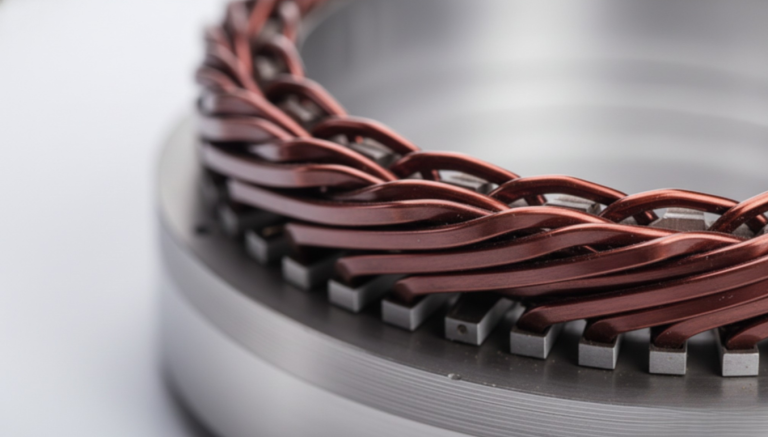

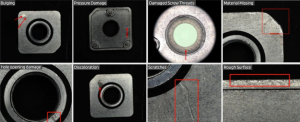

Defect Gallery

The images below showcase the system’s ability to peer inside bores and detect minute surface irregularities.

From damaged internal screw threads to subtle bulging, the UnitX AI identifies critical functional defects

Conclusion

In the production of ADAS components, precision is the only option. The Automotive Camera Module case study demonstrates UnitX’s ability to handle complex 3D geometries. By utilizing a 6-camera setup driven by AI, we ensure that the housing protecting the car’s “eyes” is perfect—inside and out.

Need to inspect complex 3D parts?

Contact UnitX to design a multi-camera solution for your product.