Introduction: When “Automated” Isn’t Enough

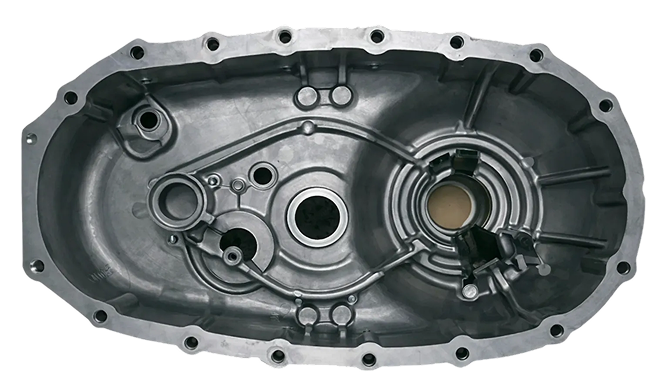

The Transfer Case is a critical component in AWD and 4WD vehicles, splitting power between axles. The housing is a large aluminum casting, and its sealing surfaces must be perfect. Any imperfection—like a burr or a porous spot—leads to oil leaks, premature wear, and costly warranty claims.

Our client thought they had this solved. They had already installed a vision system to inspect the housings. But there was a problem: it wasn’t working. Defects were slipping through (“escapes”), reaching the assembly line, and threatening their relationship with the automotive OEM.

The goal wasn’t just to install a system; it was to stop the bleeding. They needed a solution that actually worked, and they needed it fast.

The Challenge: Casting Defects on Sealing Surfaces

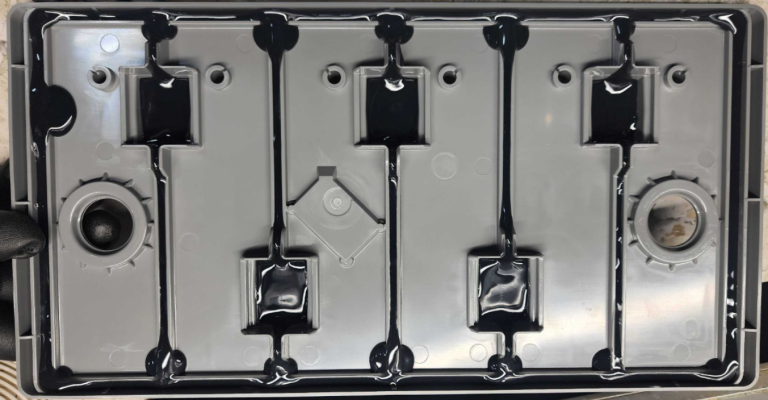

The inspection focused on the Sealing Surface of the cast aluminum housing.

The defects were specific to the casting and machining process:

- Non-cleanup: Areas where the casting wasn’t properly machined.

- Flashing: Excess metal sticking out from the casting mold.

- Chunking: Missing pieces of metal.

The challenge was to detect these rugged, 3D defects reliably without slowing down the line.

The sealing surfaces of this complex casting must be free of flashing and chunking to prevent oil leaks

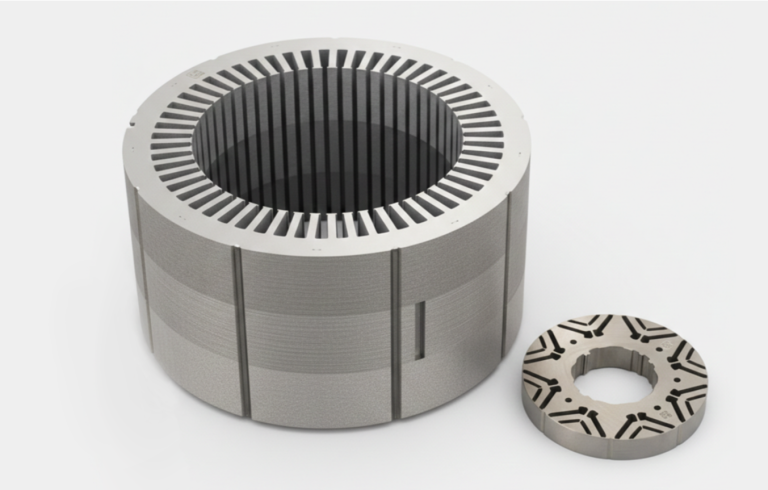

The Solution: 6-DOF Robotics & Large FOV Imaging

UnitX integrated a high-speed solution directly into the customer’s existing line.

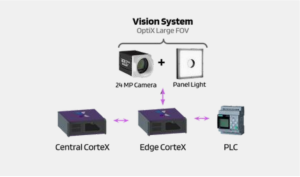

UnitX combines a Large FOV OptiX system with 6-DOF robotic movement for flexible inspection

System Approach:

- Robotic Handling: The heavy transfer case is moved using a 6-DOF (Degrees of Freedom) robotic arm, presenting the part to the camera at the perfect angle.

- Optics: We utilized a UnitX OptiX Large FOV (Field of View) system. This provides uniform illumination across the large part, crucial for distinguishing between shadow and “chunking.”

- Computing: A split architecture with Edge CorteX for immediate processing and Central CorteX for AI model management.

Results: Speed and Accuracy Redeemed

UnitX didn’t just meet the requirements; we shattered the performance of the previous system.

1. 100% Detection Accuracy False Acceptance Rate: 0%.

- False Rejection Rate: 0%.

- During the validation process, the system achieved perfect scores. It caught every instance of “Non-cleanup” and “Flashing” without flagging good parts. The “escape rate” problem was solved immediately.

2. Lightning Fast Integration)

- Days to SAT: 5 Days.

- From installation to Site Acceptance Testing (SAT) took less than a working week. This rapid deployment minimized downtime and quickly restored the end-user’s confidence.

3. Sub-Second Cycle Time

- Cycle Time: 0.39 seconds.

- The vision processing is virtually instantaneous. The system captures and analyzes the image in under half a second, ensuring the inspection is never the bottleneck.

Defect Visualization

The images below show how the AI segments defects. Notice the clear red outline around the “Flashing” (excess metal) and “Chunking” (missing metal).

UnitX AI clearly identifies casting defects like chunking and flashing that the previous system missed

Conclusion

Just because you have a camera on your line doesn’t mean you have quality control. If your current vision system is allowing defects to escape, it is a liability, not an asset. This case study proves that replacing an underperforming system with UnitX can yield immediate results: 100% accuracy, 0.39s speed, and restored customer confidence.

Is your vision system letting defects slip through?

Contact UnitX for a system audit and upgrade.