Introduction: The “Impossible” Trade-off

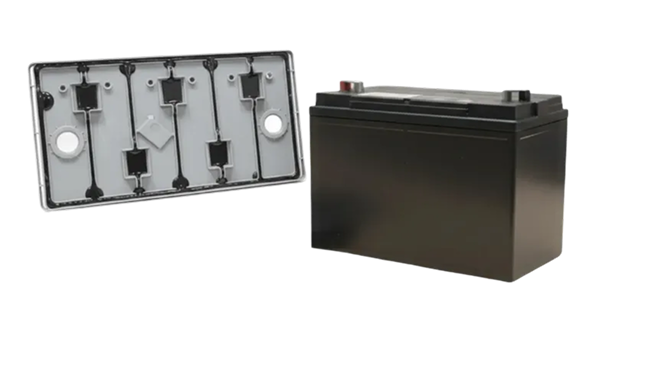

Gears are the muscle of any vehicle, transmitting power directly to the wheels. A defect here—whether a crack, a missing tooth, or a burr—leads to uneven operation, noise, safety risks, and expensive recalls.

Automotive OEMs demand perfection, mandating suppliers to implement rigorous inspection. But for our client, this created a nightmare scenario. Their previous vision system faced a crippling trade-off:

- If they tuned it to catch all defects (low False Acceptance), the system became paranoid and rejected 50% of good parts (False Rejection).

- This “overkill” blocked any chance of reducing labor or improving OEE (Overall Equipment Effectiveness). They were stuck manually re-checking half their production.

The challenge: Break this trade-off. Deliver a system that catches defects without scrapping good products.

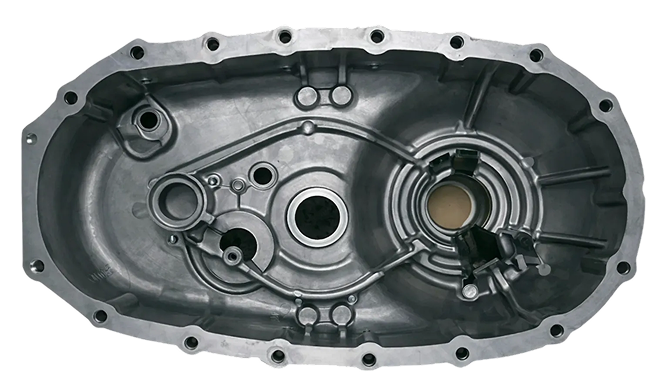

The Project: 14 Surfaces, Mixed Production

The scope was complex. The line produced mixed variants simultaneously:

- Product Diversity: 9 types of Active Chain Wheels + 2 types of Parking Gears.

- Inspection Scope: 5 specific gear variants needed a “unified inline inspection” covering 14 critical surfaces (outer gear side, inner machining surfaces, gear front, etc.).

- Speed: Everything had to happen within a tight cycle time.

Complex gear geometries require inspection of 14 different critical surfaces

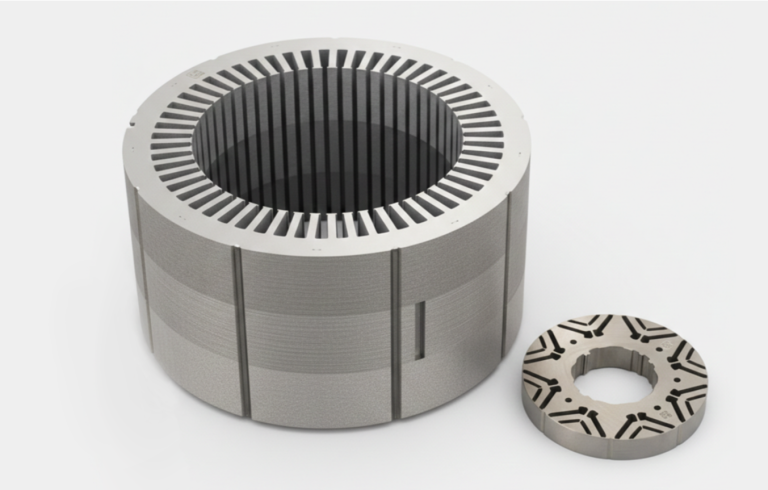

The Solution: A Robotic Unified Cell

UnitX deployed a unified inline AI inspection cell that is a marvel of automation.

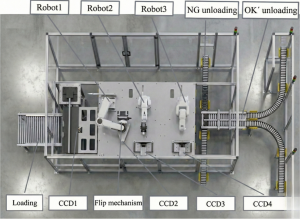

The UnitX cell features 3 robots and a flip mechanism to inspect every angle of the gear

How it Works:

- Automation: Three robots handle the loading, unloading, and sorting.

- 360° Vision: The gear moves through four CCD stations and utilizes a flip mechanism to ensure all 14 surfaces are clearly captured.

- AI Power: A cluster of 3x UnitX CorteX Inspection Cells processes the high-resolution images from 3x UnitX OptiX systems in parallel.

Results: Unlocking OEE

UnitX didn’t just meet the technical specs—it solved the deep-seated operational failures that legacy systems couldn’t touch. By bridging the gap between accuracy and speed, we transformed the client’s production floor from a bottleneck into a benchmark of efficiency.

1.Resolving the Yield Crisis

The previous system forced a costly choice between quality and volume: meeting strict safety targets meant suffering a catastrophic 50% False Rejection Rate (FRR)

-

The UnitX Solution: We slashed the False Rejection Rate to ≤ 3%.

-

Operational Impact: By reclaiming 47% of previously “wasted” parts, the client recovered lost margins and eliminated the overhead of redundant manual inspections.

-

The Gold Standard: With a False Acceptance (FA) rate of just 0.05%, the system provides near-perfect containment.

-

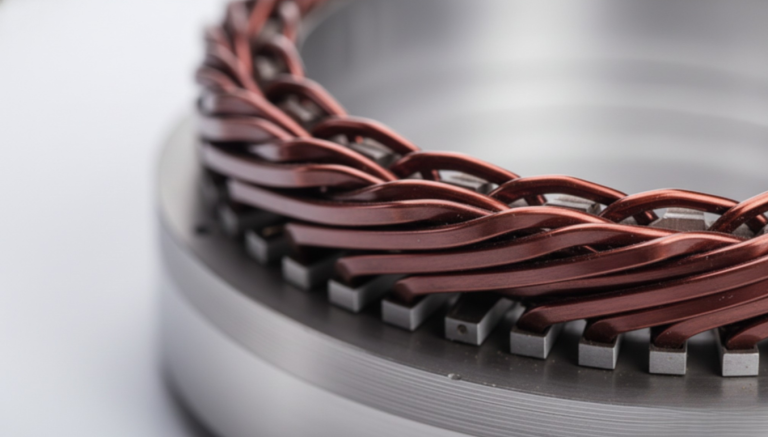

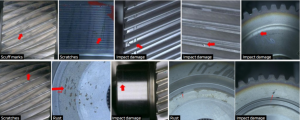

Total Defect Detection: From structural sand holes and impact damage to environmental rust and scuff marks, every part is verified for both safety and aesthetic perfection.

2.High-Velocity, Mixed-Model Versatility

- Exceeding Requirements: While the client required a 16-second cycle, UnitX delivered a 9–12 second cycle time.

- Mixed-Line Agility: The system simultaneously handles multiple gear types on a single line, providing 100% inspection coverage without requiring line stops or manual changeovers.

From subtle scuff marks to oxidation (rust), the AI detects defects that compromise gear life

Conclusion

In automotive manufacturing, “safety” shouldn’t come at the cost of “waste.” If your current vision system forces you to choose between catching defects and keeping your yield high, it’s time for an upgrade. UnitX proved that with advanced AI, you can have both: 0.05% defect leakage and high production efficiency.

Is your current vision system scrapping good parts?

Contact UnitX to see how we can improve your OEE.