Introduction: The “Live Feed” Fatigue

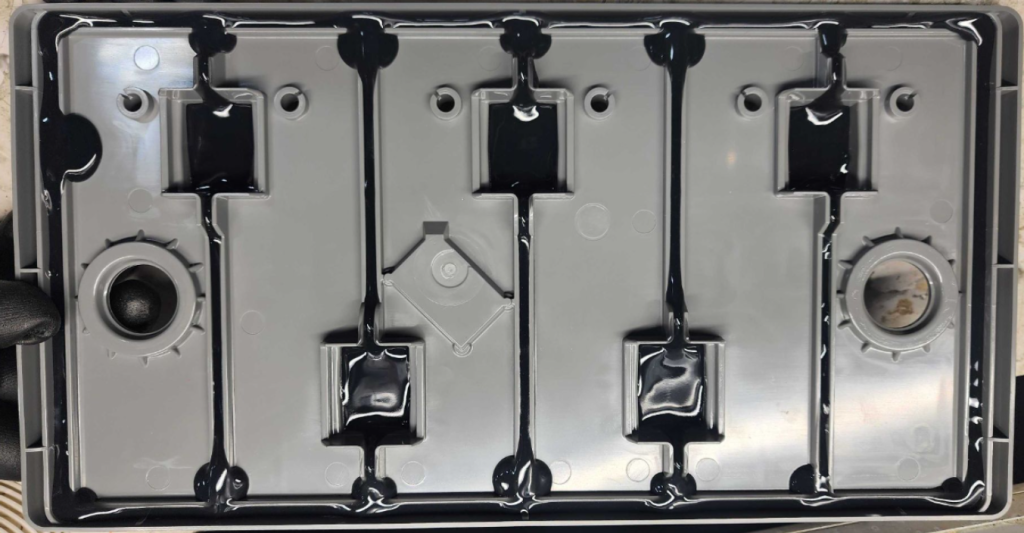

In battery manufacturing, the epoxy seal on the lid is the final barrier against the elements. Any deviation in application—such as air bubbles, path gaps, or insufficient volume—compromises the seal’s integrity, posing severe leakage and safety risks.

Our client faced the complex challenge of identifying translucent epoxy defects across a range of surface finishes, where low visual contrast frequently compromises the reliability of traditional inspection.

Previously, they relied on a “Live Feed Camera”—a passive video monitoring system. This required operators to manually verify the epoxy dispense for every unit by watching a continuous screen feed in real-time. This approach was not only labor-intensive but highly susceptible to “inspection fatigue.” Over time, the subtle visual cues of a gap or bubble became easy to miss, leading to inconsistent quality standards. It became clear that the client needed to evolve from subjective manual observation to an autonomous, data-driven inspection solution.

The Challenge: Seeing the Clear on the Shiny

The project goal was to replace the human operator with an AI system that could quantitatively measure the epoxy application.

- Target Metrics: False Acceptance (FA) < 1%, False Rejection (FR) < 5%.

- Defect Targets: Identifying minute Air Bubbles (voids) and Gaps (shortages/low level) in the epoxy bead.

- Cycle Time: The inspection had to complete in < 15 seconds to match the robotic dispensing speed.

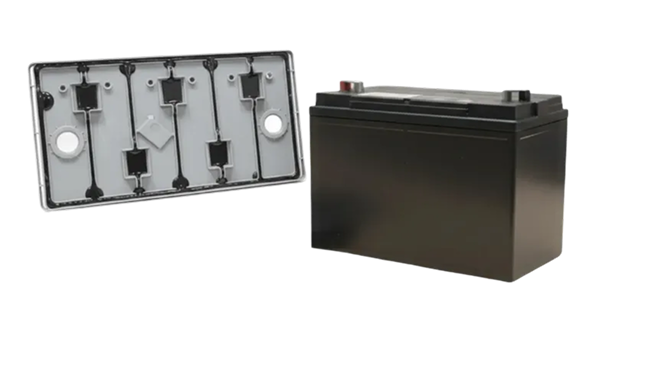

The complex geometry of the battery lid makes consistent epoxy application—and inspection—a challenge

The Solution: A Robotic “CorteX Edge” Upgrade

UnitX deployed a robust, robotically automated solution across two production lines.

System Architecture:

To maintain high spatial resolution across the entire field of view, we utilized a high-spec optical setup:

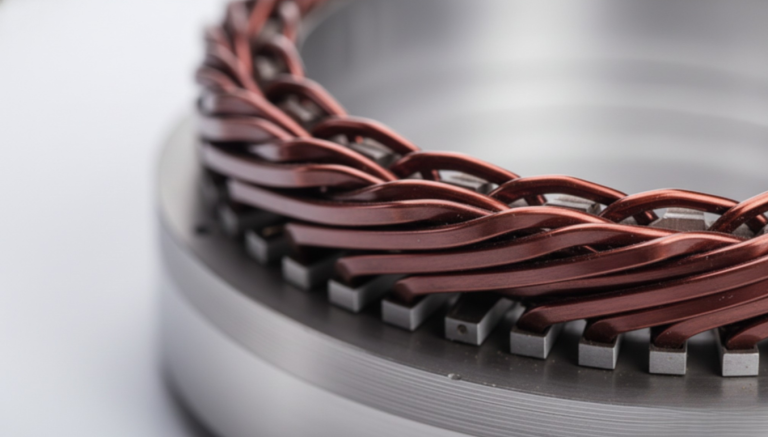

- The “Eye”: A Large FOV (Field of View) UnitX OptiX system paired with a 24 MP camera and panel light. This combination provides the necessary contrast to see transparent epoxy against metal.

- The “Brain”: A UnitX CorteX Edge unit handles the processing locally, ensuring low latency.

The UnitX inspection cart, integrated directly into the robotic dispensing line

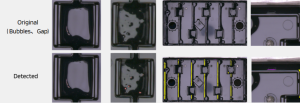

Results: Achieving the “Impossible” 0/0 Split

The shift to an AI-driven architecture exceeded all projected KPIs. Formal validation confirmed that the system delivered a stabilized quality control framework alongside a measurable increase in production yield.

1.The “Zero-Error” Benchmark:

- Zero Escapes (0% False Acceptance Rate): Absolute detection of every bubble and gap, ensuring that potential leakage risks are mitigated at the source before they can become costly warranty claims.

- Yield Optimization: This system achieves a 1.48% False Rejection Rate, drastically reducing the “overkill” common in traditional vision systems. By eliminating false flags, it preserves yield and prevents the unnecessary disposal of high-quality parts.

2. Rapid Deployment

- Days to SAT: 12 Days per line.

From installation to Site Acceptance Testing (SAT) took less than two weeks. This rapid speed meant the client could realize the value of the system almost immediately.

3. Operational Excellence

- Elimination of Warranty Claims: By catching seal defects at the source, the client stopped shipping potential leakers.

- Reduced Labor Costs: The operator previously assigned to watch the live feed was repurposed, and the inspection is now fully automated and conducted robotically.

UnitX AI visualizes defects that are hard to spot manually, clearly marking air bubbles and epoxy gaps

Conclusion

Reliance on operators for “Live Feed” manual inspection is a bottleneck that modern manufacturers can no longer afford. This case study demonstrates that even for difficult materials like transparent epoxy on metal, UnitX AI can achieve 100% detection accuracy. The result? Less scrap, zero warranty claims, and a safer final product.

Stop staring at live feeds. Start automating.

Contact UnitX to upgrade your dispensing lines today.