Introduction: The Weakest Link in the Battery Pack

A battery pack is only as strong as its weakest connection. The Tab Weld Points serve as the critical electrical links that bind individual cells into a cohesive power unit.

If these welds are defective—whether due to an “open circuit” from a missing weld or a short from “weld bridging”—the consequences are severe. Performance degrades, pack life shortens, and the risk of costly recalls or safety incidents skyrockets.

For high-volume manufacturers, the challenge is not just detecting these defects, but doing it at a massive scale. How do you inspect hundreds of thousands of weld points every day without employing an army of inspectors?

The Challenge: Manual Inspection Hit a Wall

Our client, a major battery manufacturer, faced a bottleneck. Their production targets required a daily throughput of 16,000 pieces.

Relying on manual inspection was no longer feasible. It was too slow, too inconsistent, and too costly.

The project requirements were rigorous:

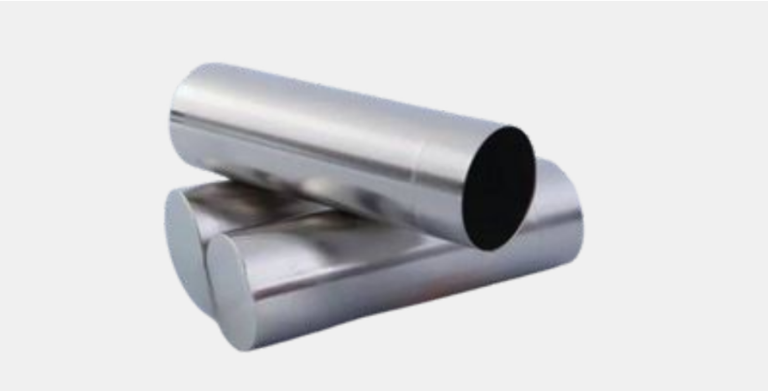

- High Variety: The system had to support multiple product sizes -lengths of 60–120 mm, Widths of 40–85 mm) —while ensuring rapid changeovers..

- Dual-Sided Inspection: Defects can occur on the front or back, so the system needed to “see” both sides instantly.

- Strict ROI Goals: The transition to automation required more than just “assistance.” The system had to deliver the uncompromising stability needed to move to a fully autonomous, high-speed inspection line.

The Solution: Deep Learning at Scale

UnitX deployed an upgraded weld inspection machine leveraged by Deep Learning. Unlike traditional rule-based algorithms that struggle with the organic variations of a weld spot, our AI models classify anomalies based on thousands of learned examples.

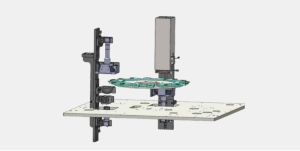

System Architecture:

- Dual-Station Design: The machine inspects both sides of the product simultaneously to maximize efficiency.

- Real-Time Decision: The CorteX AI Central and Inspection Cell units process images instantly, providing a clear OK/NG result to the production line control system.

- Imaging: Dual UnitX OptiX systems capture the high-resolution detail necessary to spot microscopic burn-throughs or offsets across the entire production line..

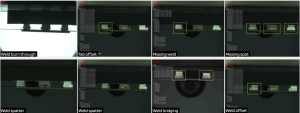

Detecting the “Dirty” Dozen

The AI successfully identifies a complex array of weld defects that often escape human eyes:

- Critical Safety Issues: Weld burn-through (puncturing the tab) and weld bridging (causing shorts).

- Process Errors: Missing welds, missing spots, and weld spatter.

- Alignment Issues: Tab offset and weld offset.

Why Leading Manufacturers Trust UnitX: Enterprise-Grade ROI

Transitioning from a pilot to a full-scale industrial transformation requires a partner that can deliver more than just software. UnitX has proven that “Scale” and “Certainty” go hand-in-hand.

- Massive Workforce Optimization: In a single major deployment, a customer successfully integrated over 80 AOI devices,enabling the reallocation of 160+ manual inspectors. This represents a monumental shift in operational efficiency and a record-breaking return on investment.

- Built for High-Velocity Production: Our systems are engineered for the “beat rate” of modern industry. They process 16,000 pieces daily with a precision-engineered 3-second cycle time, ensuring quality control never becomes a bottleneck.

- The Zero-Escape Standard: We maintain a strict 0% False Acceptance Rate on critical defects. Even at extreme speeds, the system ensures the False Rejection Rate stays at ≤0.5%, protecting yield and bottom line simultaneously.

Conclusion

Scaling production doesn’t mean you have to scale your headcount. This case study demonstrates that with the right AI vision partner, manufacturers can achieve massive throughput (160k/day) while actually reducing labor dependency. UnitX delivered stability, speed, and significant cost savings at an enterprise scale.

Ready to replace manual inspection at scale?

Contact UnitX to discuss how we can deploy fleet-level inspection solutions for your facility.