Introduction: The Foundation of a Safe Battery

Before a cylindrical battery is filled with electrolyte or sealed, it starts as a simple metal housing (can). While it looks like a basic component, its quality is the cornerstone. A dent in the wall can affect thermal dissipation; a burr on the port edge can damage the cap; oil stains or “drag marks” inside can contaminate the chemical reaction.

However, inspecting these housings is one of the toughest optical challenges in the industry. Why? Because you aren’t just looking at the outside of a shiny, curved cylinder; you have to look inside a narrow, dark tube.

Traditional Automated Optical Inspection (AOI) systems often fail here. They can’t get the right lighting or viewing angle to see defects deep on the inner walls or bottom face.

The Challenge: Reaching the Unreachable

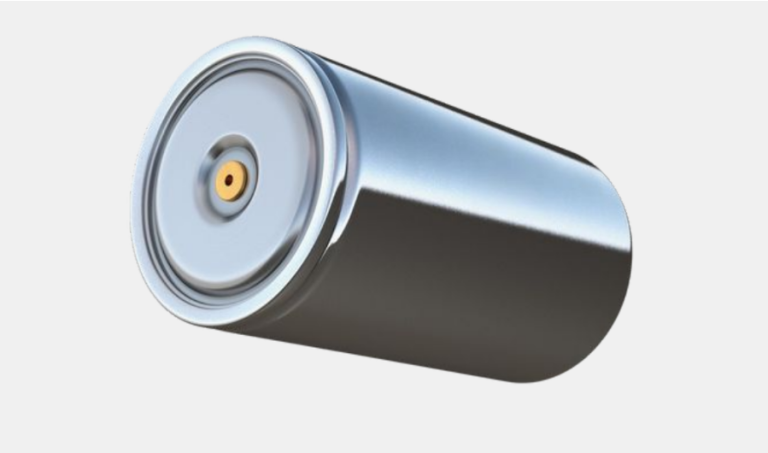

The project goal was to deploy a retrofit system capable of inspecting all critical surfaces—both the exterior and the hard-to-reach interior.

The Complexity Checklist:

- Geometry: The inner walls and “mouth” areas are difficult to access optically.

- Reflectivity: The metallic surface creates complex specular reflections that hide scratches and dents.

- Defect Variety: The system needs to detect everything from black spots and oil stains to port-edge burrs and specific manufacturing flaws like wire-drawing marks.

The Solution: Enter the Endoscope

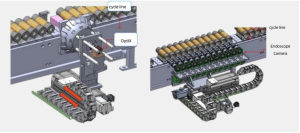

To solve the “inner wall” problem, UnitX went beyond standard lenses. We engineered a solution that integrates Endoscope Cameras directly into the vision line.

System Architecture:

- The “Inside” View: Endoscope cameras physically extend the vision system’s reach, capturing high-resolution images of the inner bottom and walls that external cameras simply cannot see.

- The “Outside” View: A standard UnitX OptiX system handles the rapid inspection of the outer cylindrical body.

- The Brain: The massive amount of data from these multiple angles is processed by a UnitX CorteX cluster (AI Central + Inspection Cell), ensuring no bottleneck in processing.

Detecting Defects, Inside and Out

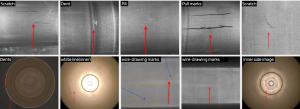

The combination of hardware innovation and AI software allowed the system to visualize defects that were previously hidden. The AI successfully identifies:

- Exterior: Scratches, dents, and pits.

- Interior: White lines, drag marks, and bottom dents.

- Manufacturing Flaws: Pull marks and wire-drawing marks.

The Results: Reliability at Speed

The system is currently operating with tight accuracy tolerances that strain conventional setups, yet it delivers consistent results.

- Total Containment

- False Acceptance Rate= 0%.

- Whether the defect is on the outside or hidden deep inside, the system catches it. No bad housings move forward to the filling stage.

- High-Speed Production

- Production Cycle Time: 0.75 pc/sec.

- The system inspects approximately 45 cans per minute, keeping pace with the rapid stamping and cleaning processes of housing manufacturing.

- High System Uptime

- System Fault Rate: ≤ 0.5%.

- This metric refers to downtime attributable solely to the vision system. The low rate indicates a robust, industrial-grade build that doesn’t require constant maintenance or rebooting.

Conclusion

The Cylindrical Battery Housing case proves that there is no such thing as a “hidden” defect when you have the right technology. By combining AI with endoscopic imaging, UnitX turns the “hard-to-reach” dark spots of a battery can into fully illuminated, fully inspected surfaces.

Need to inspect deep inside your components?

Contact UnitX to learn about our endoscopic and specialty vision solutions.