Introduction: The Limits of Manual Inspection

As cylindrical battery production scales to meet market demand, quality control for the positive electrode remains pivotal. This inspection is challenging because minute defects on reflective, curved surfaces are difficult to detect at high production speeds.

For many manufacturers, manual inspection has traditionally been the default approach. But human eyes—no matter how trained—fatigue over time. This leads to “traceability gaps” where missed faults slip through, elevating the risks of short circuits, thermal runaway, and costly warranty claims. Furthermore, as cycle times tighten, manual labor simply cannot keep up.

The goal of this project was straightforward but ambitious: Replace manual labor with a fully automated system that improves quality standards while delivering a tangible Return on Investment (ROI).

The Challenge: Tiny Defects on Shiny Surfaces

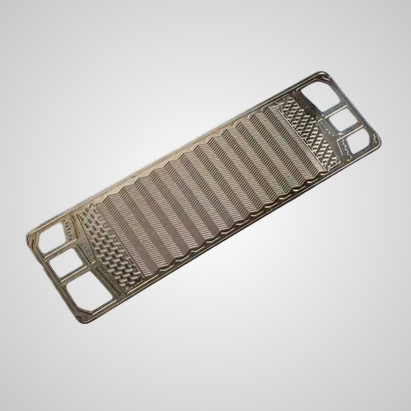

The project required detecting minute defects on the reflective metal cap of the battery. The specific challenges included:

- Complex Defect Types: The system needed to identify everything from structural deformation and missing welds to microscopic laser welding pinholes and delamination.

- High-Speed Requirements: The target cycle time was extremely aggressive to match production throughput.

- Flexibility: The line produces 4 different compatible types of batteries, requiring a system that can handle changeovers without complex reconfiguration.

The Solution: Scalable AI Inspection

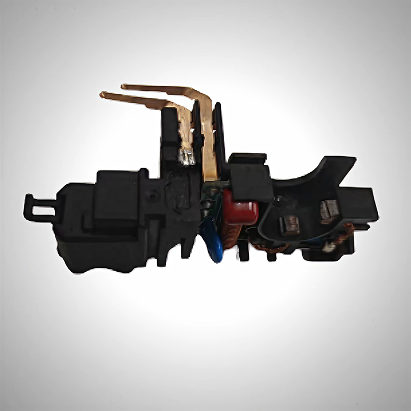

UnitX deployed a multi-station vision solution capable of inspecting batches of 8 batteries at once.

- Fly-Capture Technology: The system utilizes fly-capture imaging at a speed of 40mm/s, allowing it to snap high-resolution images without stopping the movement of the battery tray.

- Hardware Efficiency: Powered by a lean setup of one UnitX OptiX imaging system and CorteX AI processing units, the system is scalable across multiple stations.

- Defect Recognition: The AI was trained to see through the reflection, identifying issues like “Edge exposed welding” and “Poor edge welding” that often look like normal lighting variations to standard cameras.

Speed, Safety, and Savings

The deployment of this automated system delivered immediate, quantifiable business results.

1.High ROI: Labor Cost Reduction

Automation isn’t just about technology; it’s about economics.

- Workforce Efficiency: 2 QC staff were reduced immediately following deployment.

By automating this difficult task, the manufacturer reallocated human resources to higher-value tasks, significantly lowering operational costs.

2.Unmatched Speed

The system is incredibly fast, processing batteries faster than the blink of an eye.

- Vision Cycle Time: 0.25 seconds per piece.

- Overall Machine Cycle Time: 0.9 seconds per piece.

3.Superior Quality Control

The system exceeded its original targets for accuracy.

- Significance: Zero critical defects leaked to the customer.

- Significance: With an FR ≤ 1%, the system is highly precise, wasting far less material than the previous manual or semi-automated methods.

Conclusion

This case study demonstrates that replacing manual inspection with AI is not just a safety upgrade—it is a smart financial move. With a vision cycle time of 0.25s and a 0% escape rate for defects, UnitX provides the reliability that the battery industry demands, while delivering the efficiency that the bottom line requires.

Ready to automate your QC process?

Contact UnitX to calculate the ROI of automating your inspection lines.