Introduction: The Mylar Inspection Challenge

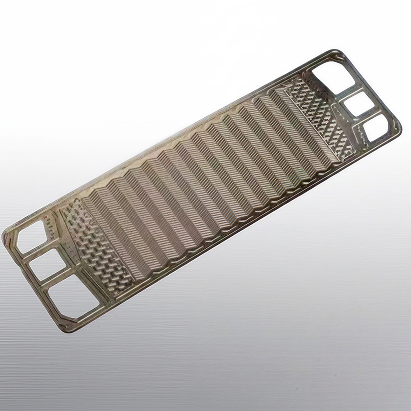

In the final stages of Lithium-ion battery assembly, cells are often wrapped in Mylar (PET film) to provide essential electrical insulation and mechanical protection. While Mylar is excellent for protection, it is notoriously difficult to inspect automatically.

Why? Mylar is reflective, flexible, and prone to surface variations. When a battery cell travels down the line wrapped in this material, detecting defects like blisters, wrinkles, or transparent oily residues against a shiny background is a nightmare for traditional machine vision. Furthermore, as production demands increase, these inspections must happen on the fly—without stopping the line.

The Challenge: Speed vs. Clarity

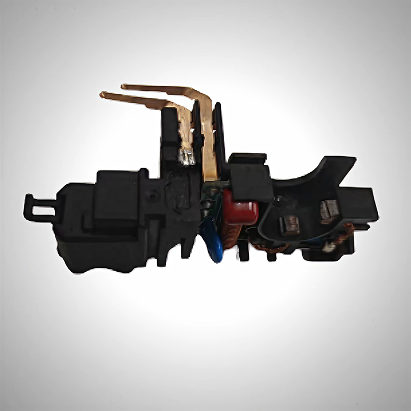

The specific project goal was to perform a comprehensive inspection of both the front and back surfaces of the Mylar-wrapped cell immediately after overmolding and adhesive application.

The hurdles were significant:

- Reflective Surfaces: The glossy nature of Mylar easily leads to overexposure (glare) or underexposure (shadows), hiding defects.

- Defect Variety: The system needed to catch a wide spectrum of issues, from obvious metallic foreign objects to subtle blisters (air bubbles) and transparent adhesive residue.

- Sampling Resolution vs. Cycle Time: Achieving the sub-millimeter pixel resolution required to detect micro-defects across the entire cell surface—while maintaining the high-velocity throughput of the production line—demands massive data processing power without introducing latency.

The Solution: Staggered Optics & Fly Capture

UnitX implemented a sophisticated “Fly Capture” solution, meaning the system inspects the battery while it is in motion (at speeds of 250mm/s), rather than stopping it.

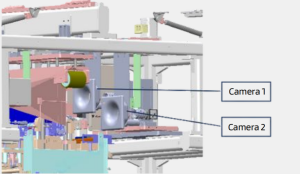

To address the large surface area, we employed a unique vertically staggered configuration using UnitX OptiX units.

UnitX Visual Inspection System Highlights:

- Expanded Coverage: By staggering two OptiX units vertically, the system ensures 100% height coverage and utilizes advanced image stitching to generate a high-resolution image composite of the entire battery surface for holistic analysis.

- Smart Lighting: Custom light patterns neutralize Mylar’s surface glare, exposing ‘invisible’ defects typically obscured by high-gloss substrates.

- Edge-AI Processing Power: Featuring 4 synchronized OptiX imaging systems and UnitX CorteX AI central, the hardware architecture delivers the high-speed processing necessary for real-time, AI-driven defect detection.

Capturing the Invisible

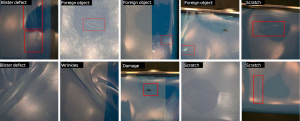

The AI model proved its robustness by detecting defects that are often invisible to the naked eye under conventional lighting. The system successfully identifies:

- Foreign Objects: Both metallic and non-metallic debris.

- Surface Flaws: Scratches, damage, and wrinkles in the film.

- Process Defects: Blisters (bubbles under the film) and oily residues.

The Results: Precision at 250mm/s

UnitX Visual Inspection system’s performance in a live production environment demonstrated that high speed does not require sacrificing accuracy.

- Total Defect Containment: With a 0% escape rate, the system provides 100% confidence in every unit shipped. No scratches, contaminants, or blisters passed through the visual system.

- Solving the “Over-Kill” Problem: Because Mylar’s surface is visually “noisy,” standard sensors often reject good parts. UnitX’s intelligent discrimination maintains an ultra-low FR≤ 0.5%, ensuring only scrap what is truly broken.

- High-Velocity Capture: Operating at 250mm/s, with fly-capture technology eliminates the need for the line to “stop and wait.” The result is a ≤2 second cycle time that keeps daily throughput at its peak.

The inspection keeps pace with the fastest assembly lines, ensuring quality control is never the bottleneck.

Conclusion

Inspecting Mylar-wrapped cells doesn’t have to be a trade-off between speed and accuracy. With UnitX’s optimized lighting and AI-driven fly capture technology, manufacturers can ensure that every cell entering the final assembly is perfectly insulated and defect-free.

Looking for high-speed inspection solutions?

Reach out to the UnitX team to discuss your surface inspection challenges.