Introduction: The Invisible Threat to Battery Safety

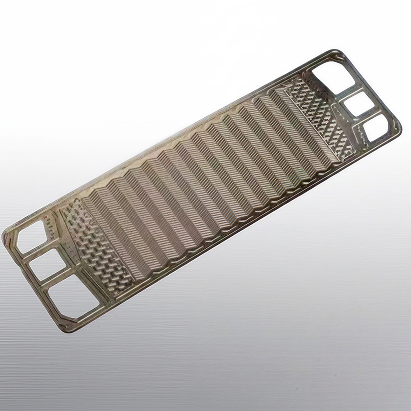

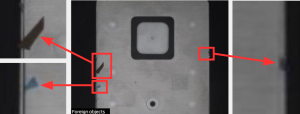

In prismatic lithium-ion battery manufacturing, can edge sealing is pivotal to ensuring hermetic integrity and long-term safety. Any defect at this stage directly impacts battery reliability and lifespan performance. During the “cell-into-can” insertion process, microscopic foreign materials—such as excess adhesive, fragments of Mylar, or Teflon tape—can become lodged in the pre-weld gap. If these contaminants are not detected before welding, they compromise the weld’s integrity. The result? Poor seals, potential short circuits, and safety hazards that threaten the battery’s life cycle.

The goal is simple yet demanding: Transform the invisible to visible –replace manual labor with an automated system that catches 100% of these foreign objects without slowing down the production line.

The Challenge: Spotting the Invisible in the Gap

The “pre-weld gap” is a narrow, hard-to-inspect area.Traditional inspection relies on manual intervention, which is labor-intensive, prone to human error, and yields inconsistent quality. The challenges in overcoming this situation included:

- Material Differentiation – Accurately distinguish the metal from adhesives, tape, or plastic fragments to ensure only real defects are flagged.

- Process Integration: Inspect immediately after the top cover is placed but before welding, catching contaminants without slowing production.

- Data Traceability – Log defect details for each battery, enabling root-cause analysis and continuous process improvement.

The Solution: UnitX’s Pre-Weld Gatekeeper

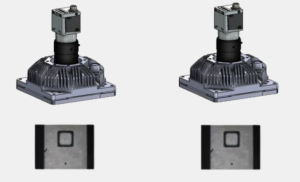

UnitX deployed a high-precision visual inspection system acting as a strict gatekeeper before the welding station.

The system inspects the can mouth and top cover specifically for foreign material overflow. If a foreign object exceeds the set threshold, the unit is immediately flagged as NG (No Good). Crucially, the system reads the barcode and transmits the specific defect result to the customer’s MES (Manufacturing Execution System), ensuring the faulty unit is automatically rejected before it ever reaches the welding laser.

System Configuration:

- Optics: Two UnitX OptiX imaging systems provide the visual clarity needed to see into the gap.

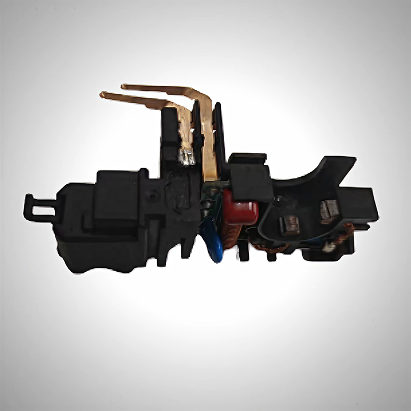

- Processing Power: A dual-CorteX setup (AI Central and Inspection Cell) handles the image processing and AI inference instantly.

AI Performance: Precision meets Efficiency

The AI model was trained to recognize specific foreign contaminants common in battery assembly, including adhesive residues, Mylar, and Teflon. The results from the production line highlight the system’s ability to balance extreme safety with high efficiency.

Manual vs. AI-Driven:

The move to automated optical inspection (AOI) eliminates the inconsistencies of human fatigue, resulting in a significantly more stable and predictable production line.

- Zero-Defect Safety: Our AI models serve as a “reliable safeguard” against critical defects. By maintaining a 0% False Acceptance Rate, the system guarantees that no foreign material survives the gap-inspection phase.

- Superior Vision Intelligence: Traditional vision systems often struggle with “false fails” caused by reflections. The UnitX AI is trained to filter out harmless optical noise, achieving an FR ≤ 0.2%. This minimizes the cost of re-checking good batteries and reduces waste.

- High-Speed Synchronization: With a sub-2-second cycle time, the system is designed for high-velocity assembly environments, providing real-time verification that keeps the production line running at its peak “beat rate.”

Conclusion

For prismatic battery manufacturers, the pre-weld stage is a critical quality control checkpoint. By implementing UnitX’s AI inspection, manufacturers can eliminate the risk of compromised seals caused by foreign debris. This solution not only protects the final product but also digitizes the quality process, feeding valuable data back into the manufacturing ecosystem.

Ensure your battery welds are contaminant-free.

Contact UnitX to discuss our pre-weld inspection solutions.