Introduction: The “Soft” Challenges in Battery Manufacturing

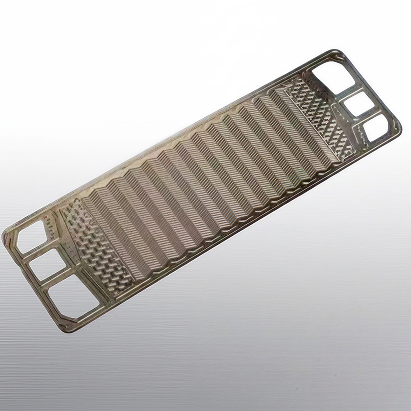

In the rapidly evolving Electric Vehicle (EV) and consumer electronics sectors, pouch cells have become a preferred energy storage solution due to their high energy density and design flexibility. However, their greatest strength is also their greatest vulnerability: their structure.

Unlike cylindrical or prismatic batteries, pouch cells are encased in a flexible aluminum-plastic film. This makes them highly susceptible to pressure damage, scratches, and seal failures during the manufacturing process. A single overlooked pinhole or a compromised seal isn’t just a quality issue—it is a safety hazard that can lead to leaks, short circuits, or even thermal runaway (explosions).

For manufacturers, the goal is clear but difficult: How do you perform a rigorous, 360-degree inspection of a fragile object at high production speeds without missing a single critical defect?

The Challenges: Blind Spots and Fragile Surfaces

Inspecting pouch cells presents a unique set of difficulties for traditional machine vision systems:

- Complex Geometry: A pouch cell has six distinct surfaces—front, back, seal edges, side edges, and tab faces. Traditional cameras often struggle with the depth of field and lighting required to see all sides simultaneously.

- Reflective & Texture Issues: The aluminum foil can be highly reflective, while defects like dents or “foil protrusions” can be subtle and difficult to distinguish from normal surface variations.

- Zero Tolerance for Error: In the battery industry, a critical defect cannot be allowed to pass. The False Acceptance Rate (FAR) for safety-critical issues must be effectively zero.

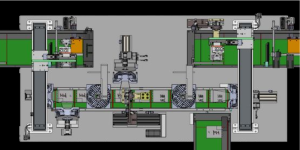

The Solution: UnitX’s 6-Station AI Inspection Line

To address these challenges, UnitX deployed a custom-engineered inline visual inspection system designed specifically for the rigorous demands of the battery industry.

Our system utilizes a six-station AI line that inspects every surface of the bare pouch cells. By integrating optimized multi-angle lighting, the system can reveal surface topography that flat lighting would miss, such as subtle dents or foil protrusions.

System Architecture:

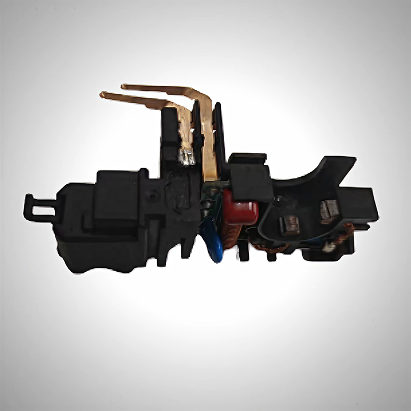

At the heart of this solution lies UnitX’s proprietary hardware and software ecosystem:

- AI Compute: Powered by CorteX (AI Central and Inspection Cell units) to process high-resolution data in real-time.

- Imaging: Utilizing OptiX vision system to capture sub-visible defects through high-resolution imaging of the cell’s surface and edges.

Detecting the Undetectable

The system was trained to identify a wide range of defect types, categorizing them into critical and non-critical groups. The AI model successfully detects:

- Surface Integrity: Scratches, dents, and deformation.

- Material Flaws: Foil protrusion (dots), pinholes, and contamination.

- Seal & Tab Issues: Leaks and tab deformations.

Speed Meets Safety in the Real World

What does production-ready AI look like? After deploying UnitX on the front lines to see how it handled real-world volume. The numbers speak to a system designed for the enterprise:

- 0% Escapes: Total protection against critical safety defects.

- 2.5s Cycle Time: Lightning-fast inspection that syncs with production line’s beat rate.

- ≤5% False Rejection Rate: Significant savings by minimizing false rejection rates.

- ≤0.05% Visual Excellence: High-fidelity grading for a flawless product finish.

Conclusion

As battery manufacturing scales up to meet global demand, the “set it and forget it” era of manual or simple rule-based inspection is over. UnitX Pouch-Cell Surface Inspection eliminates the compromise between throughput and precision. By combining AI with an advanced optical imaging system, UnitX ensures manufacturers NEVER have to sacrifice safety for speed.

Ready to upgrade your quality control?

Contact the UnitX team to learn how our AI visual inspection systems can be tailored to your production line.