An industrial smart camera machine vision system consists of several key components: the smart cameras, lighting, optics, processing units, and connectivity modules. Each part of the machine vision system works together to deliver accurate inspection and process automation in an industrial setting.

- Smart cameras dominate the machine vision system market because they simplify setup and reduce hardware needs.

- These systems improve quality control by enabling real-time, high-speed, and highly accurate inspection.

- Advanced analytics and built-in processing help factories achieve better quality and control, driving factory automation and operational efficiency.

Key Takeaways

- Industrial smart cameras combine image capture and processing in one device, making setup simple and inspection fast.

- Proper lighting and high-quality lenses are crucial for clear images and accurate defect detection in machine vision systems.

- Built-in AI and powerful processors enable real-time inspection and improve quality control on production lines.

- Connectivity options like GigE Vision and USB3 Vision allow easy integration with factory equipment for automation.

- Choosing the right system depends on inspection needs, environment, and required flexibility to ensure reliable performance.

Industrial Smart Camera Machine Vision System

Smart Camera Components

Industrial smart cameras form the core of any industrial smart camera machine vision system. These devices combine several essential parts into a single unit. The main components include image sensors, lenses, processors, protective covers, and built-in vision software.

| Component Category | Description |

|---|---|

| Image Sensors | CCD and CMOS sensors convert light into electrical signals. Monochrome sensors are common in industrial use. |

| Lenses | Manual, autofocus, and liquid lenses focus light onto sensors. Autofocus and liquid lenses improve accuracy. |

| Covers | Protective housings shield cameras from dust, water, and impacts. Many have IP67 ratings for harsh settings. |

| Processors | CPUs and GPUs enable image processing and support AI or deep learning. Choice depends on application needs. |

| Additional Features | Sensors vary by resolution, frame rate, shutter type, and spectral sensitivity (including IR). |

| Software Components | Vision software includes AI and image analysis algorithms for inspection and detection tasks. |

Industrial cameras come in several types, each suited for different inspection needs:

- Area scan cameras capture images in a single frame, ideal for stationary objects.

- Line scan cameras build images line-by-line, perfect for moving materials or cylindrical parts.

- 3D cameras, such as laser profilers, provide depth information for complex inspection.

- Embedded smart cameras integrate processing and AI, making them compact and flexible for factory automation.

Smart cameras handle image capture, processing, and decision-making within one device. They use CPUs, GPUs, or FPGAs to analyze images quickly. These cameras perform defect detection, pattern recognition, and object verification in real-time. Rugged housings and flexible interfaces allow them to work in harsh industrial environments. Workers can monitor and adjust settings remotely, improving productivity and safety on the production line.

Lighting and Optics

Lighting and optics play a critical role in every machine vision system. Proper lighting ensures consistent and controlled illumination, which is vital for accurate inspection and detection. LED-based lighting provides energy-efficient and reliable illumination. Specialized lighting types, such as dome, ring, coaxial, and collimated lighting, adapt to different surfaces and inspection goals. Advanced lighting controllers regulate intensity and timing, reducing motion blur and enhancing contrast.

| Lighting Technique | Description | Best Applications |

|---|---|---|

| Ring Lighting | Light mounted around the camera, illuminating directly in front. | General vision inspections, small parts inspection. |

| Backlighting | Light source behind the object creating a silhouette. | High contrast inspection, size/shape measurement, detecting holes, verifying placement/orientation. |

| Directional Lighting | Light at an angle creating shadows; includes bright-field (perpendicular) and dark-field (low angle). | Bright-field: surface features; Dark-field: surface defects, textures, shiny objects inspection. |

| Low Angle Ring Lighting | LEDs mounted in a ring at low angle to create shadows and bright spots. | Surface defects, etching, embossed marks inspection. |

| On-Axis Lighting | Light focused along camera axis using beam splitter for direct, diffuse illumination. | Eliminating shadows, inspecting shiny surfaces, detecting texture differences. |

Lenses focus light onto the image sensor of the industrial digital camera. Key lens parameters, such as focal length and aperture, affect image clarity, field of view, and depth of field. Proper selection of these parameters ensures that the machine vision system captures clear and detailed images for precise inspection and recognition. Protective covers shield industrial cameras from dust, water, and impacts, ensuring durability in tough environments.

Processing and Software

Processing and software are at the heart of industrial smart camera machine vision systems. Modern industrial smart cameras use powerful CPUs, GPUs, or even AI-specific chips to process images directly on the device. This setup eliminates the need for separate computers and reduces latency, enabling real-time inspection and decision-making.

| Component Type | Details |

|---|---|

| Processing Units | NVIDIA Jetson Nano and Xavier NX modules with AI cores and graphics processors |

| Image Sensors | Sony CMOS sensors (e.g., IMX265, IMX250) |

| Software Environment | Linux-based OS, supporting flexible programming and image processing libraries |

| Software Package | Includes vision software like NVIDIA JetPack, Baumer Camera Explorer, neoAPI, GAPI SDK |

| Integration Features | GenICam compatibility, Ethernet, RS232, SD card slots, HDMI, USB |

| Benefits | Combines image capture and processing in one unit, no need for separate PC |

| Application Focus | Real-time AI-based image processing for industrial use |

Vision software runs advanced algorithms for image analysis, defect detection, and pattern recognition. AI-enabled features allow the system to sort products, detect defects invisible to the human eye, and guide robots on the production line. AI at the edge processes data locally, reducing network load and improving privacy. These features help machine vision systems adapt quickly to new inspection tasks and maintain high accuracy.

Tip: AI-powered vision software can improve image quality by reducing noise and stabilizing images, which is especially useful in challenging industrial conditions.

Connectivity and Integration

Connectivity and integration ensure that the industrial smart camera machine vision system works seamlessly with other factory equipment. Standard connectivity options include GigE Vision, USB3 Vision, and CoaXPress. These interfaces provide high-speed data transfer and support long cable lengths, which are important for real-time inspection and automation.

| Connectivity Option | Description | Data Transfer Speed | Cable Length | Power Delivery | Industrial Integration Role |

|---|---|---|---|---|---|

| GigE Vision | Ethernet interface for smart cameras | 1–10 Gbps | Up to 100m | Power over Ethernet (PoE) | Scalable, flexible, widely used in industrial networks |

| USB3 Vision | USB-based interface for fast data transfer | Up to 10 Gbps | Few meters | No PoE | Easy integration for short-range applications |

| CoaXPress | High bandwidth interface using coaxial cable | Up to 12.5 Gbps | Up to 100m | Power over cable | Supports high data rates, ideal for advanced image processing |

Industrial digital cameras also support protocols like TCP/IP, Modbus, PROFINET, and Precision Time Protocol. These protocols allow direct integration with PLCs and factory networks, enabling automated responses such as sorting or rejecting defective products. Software platforms simplify setup and deployment, making it easy to add new vision tools or inspection capabilities as factory needs change.

- The VS40 smart camera, for example, supports Ethernet/IP, PROFINET, Modbus TCP, and RS-232, allowing direct connection to existing automation systems.

- Software upgrades let users add new inspection tools or barcode reading features without changing hardware.

All these components—smart cameras, lighting, optics, processing, and connectivity—work together to enable real-time inspection and automation. For example, a smart camera on a bottling line can read barcodes and verify labels instantly, while lighting and image processing detect crushed bottles before filling. Communication interfaces connect the system to robots or PLCs, triggering immediate action when defects are found. This teamwork ensures that machine vision systems deliver reliable, high-speed inspection and quality control in industrial environments.

Machine Vision Systems Performance

Image Quality Factors

Image quality is a key part of machine vision systems. High-quality images help the system find defects and make accurate decisions during inspection. Several factors affect image quality in an industrial machine vision system:

- Sensor resolution must be high enough so defects appear in multiple pixels for easy detection.

- The type of camera matters. Line-scan cameras work best for moving products, while area-scan cameras suit stationary items.

- The field of view should cover the whole product for complete inspection.

- Lens quality and compatibility with the sensor improve focus and sharpness.

- Lighting conditions, such as LED or strobe lighting, reduce shadows and glare, making defects easier to spot.

- Environmental factors like dust, humidity, and temperature can affect camera performance.

High-resolution smart cameras, some with up to 42 megapixels, capture fine details needed for quality control and defect detection. Multi-sensor cameras with features like polarization help reduce glare and improve contrast, making inspection more reliable. Good lighting and lens choices also support non-contact inspection and improve measurement accuracy.

Note: Proper lighting and high-quality lenses can increase detection accuracy by over 12% and reduce false positives.

Real-Time Processing

Real-time inspection is vital for industrial machine vision systems. The system must process images quickly to keep up with high-speed inspection on production lines. Processing speed depends on the camera’s frame rate, the power of the processor, and the efficiency of the vision software.

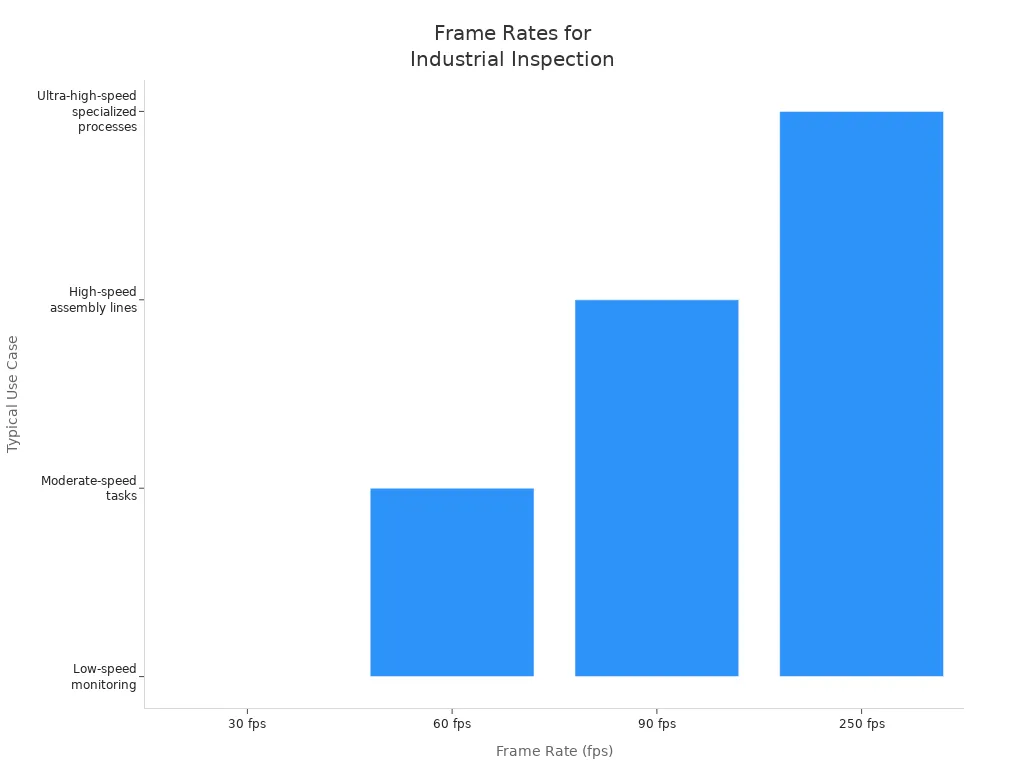

| Frame Rate (fps) | Typical Use Case | Description and Benefits | Trade-offs |

|---|---|---|---|

| 30 | Low-speed monitoring | Good for general monitoring; balances clarity and data needs | Not for fast motion |

| 60 | Moderate-speed tasks | Better motion clarity; common in packaging and bottling | Needs more bandwidth |

| 90 | High-speed assembly lines | Captures fast movements; used for machine parts | High data capacity needed |

| 250 | Ultra-high-speed specialized use | Captures very fast motion; used in robotic assembly | Needs special hardware and storage |

Most industrial systems run between 60 and 120 fps. Real-time analysis and data analysis allow the system to inspect thousands of items per minute. AI-enabled smart cameras use powerful processors to perform real-time detection, defect detection, and quality assessment directly on the device. This reduces latency and supports immediate quality control decisions.

System Scalability

Scalability is important for machine vision systems in large industrial operations. As factories grow, the system must handle more cameras, higher data volumes, and new inspection tasks. Common challenges include:

- Managing large amounts of data for storage and retrieval.

- Keeping software and algorithms efficient as the system grows.

- Ensuring privacy and security for sensitive production data.

- Adapting to changes in lighting, product appearance, and environmental conditions.

Modular designs help machine vision systems scale easily. Factories can add new cameras, upgrade processors, or expand storage as needed. Modular hardware and software platforms allow the system to grow with production needs, supporting high-speed inspection and real-time control. This flexibility ensures reliable quality control and inspection as industrial demands increase.

Industrial Smart Cameras vs Traditional Systems

Architecture Differences

Industrial smart cameras and traditional machine vision systems have different designs. Smart cameras combine the sensor, image digitization, and processing in one compact device. These cameras use embedded processors like DSPs, ARM+FPGA, or CPU+VPU. This design makes the system simple, affordable, and easy to install. Most smart cameras work well for basic inspection tasks.

Traditional machine vision systems use a different approach. Industrial cameras capture and digitize images, but send them to a separate industrial computer or PLC for processing. This setup uses more powerful computers and supports advanced algorithms. The system can handle complex inspection jobs and allows users to develop custom code. Both types of systems perform core vision tasks, but they differ in where and how they process images.

Note: Flexible and modular system designs make it easier to update or replace parts. This helps with maintenance and allows the system to adapt to new needs.

Application Scenarios

The choice between smart cameras and traditional machine vision systems depends on the industrial scenario. The table below shows where each system works best:

| Industrial Scenario | Preferred System | Reason / Advantage |

|---|---|---|

| Dynamic manufacturing environments | Smart camera machine vision systems | AI-driven adaptability, real-time quality control, predictive maintenance |

| PCB assembly | Smart camera machine vision systems | AI-powered inspection, higher accuracy than human inspectors |

| Warehouse management | Smart camera machine vision systems | Object detection, improved inventory sorting, fewer errors |

| Automotive and aerospace inspection | Smart camera machine vision systems | Deep learning, fast and accurate defect detection, real-time monitoring |

| Stable, repetitive production lines | Traditional vision systems | Reliable for simple tasks, lower setup cost, less technical skill needed |

Traditional machine vision systems remain common in food, pharmaceutical, and consumer products industries. These systems inspect packaging, count items, check labels, and verify expiration dates. In semiconductor factories, they detect flaws, inspect solder joints, and guide component placement. Automotive plants use these systems for assembly guidance and part inspection.

Pros and Cons

Industrial smart cameras and traditional machine vision systems each have strengths and weaknesses.

-

Smart cameras:

- Simple design and easy setup

- Lower cost for basic inspection

- Compact and rugged for harsh industrial settings

- Limited flexibility for complex tasks

-

Traditional systems:

- High computational power for advanced inspection

- Flexible and modular, allowing upgrades and custom code

- Better for large-scale or complex industrial applications

- Higher cost and more complex installation

Tip: Choosing the right system depends on the inspection task, the need for flexibility, and the complexity of the industrial environment.

Choosing a Machine Vision System

Application Requirements

Selecting the right machine vision system for industrial use starts with understanding the specific inspection needs. Each application has unique requirements that affect system choice.

- Resolution must match the smallest feature to inspect. For traditional systems, the 3-pixel rule applies. For AI-based systems, features should cover 5-10 pixels for reliable detection.

- Frame rate must keep up with the speed of the production line to avoid motion blur and ensure timely inspection.

- Sensor type matters. Monochrome sensors offer better sensitivity and contrast for defect detection. Color sensors are needed for color differentiation and regulatory compliance.

- Shutter type is important. Global shutters prevent distortion in moving objects, while rolling shutters suit stationary or low-cost applications.

- Lighting integration is critical. The system should allow precise control of lighting using GPIO and trigger synchronization.

- Field of view must cover the inspection area with enough pixel density for the smallest feature.

- Interface and connectivity options, such as USB 3.0, GigE, or CoaXPress, should match bandwidth needs and system architecture.

- Environmental robustness is essential. Cameras should meet industrial protection standards like IP ratings.

- Software compatibility ensures the system supports the required inspection algorithms and integrates with automation controls.

- Application-specific needs vary. Surface defect detection, assembly verification, print inspection, dimensional measurement, and material sorting each require different technical features.

Tip: Plan GPIO requirements early and avoid over-specifying resolution to balance cost and performance.

Component Selection

Component selection depends on the type of inspection and the industrial environment.

- Define the inspection requirements before choosing components.

- Start with pilot projects to test the system on actual targets.

- Ensure proper lighting and imaging conditions for the inspection area.

- Train operators and maintenance staff to use the system effectively.

- Set up clear procedures for handling defects found during inspection.

- Collect and analyze inspection data to improve quality over time.

- Maintain communication between quality, production, and engineering teams.

Key components include cameras for detailed real-time imaging, lighting tailored to the material and defect type, sensors for extra data, processing units for high-speed analysis, and software with advanced algorithms. User interfaces help with configuration and monitoring. Integration features connect the system to production and enterprise systems. For one-time inspection projects, portable or modular systems may offer the best value.

Integration Considerations

Integrating a machine vision system into an existing industrial environment brings several challenges.

- Compatibility with existing machinery and software, including PLCs, is vital.

- Environmental factors such as lighting, dust, vibration, and temperature can affect system performance.

- Complex inspection tasks may require high-resolution cameras and advanced algorithms.

- Managing large data volumes for processing and storage is often necessary.

- Regular maintenance and calibration keep the system accurate.

- Hardware and software must fit the physical size and power needs of the production line.

- Data management decisions, such as local versus remote processing, impact speed and reliability.

- The system should integrate smoothly with production control systems for efficient data flow.

- Flexible design allows the system to handle multiple inspection tasks and future upgrades.

- Skilled personnel are needed for retrofitting and ongoing maintenance.

Note: Defining a clear project scope and ensuring proper synchronization among cameras, sensors, and actuators helps avoid delays and bottlenecks.

Understanding each component in a machine vision system helps professionals improve inspection and quality. Smart cameras, lighting, and software all play a role in inspection speed and accuracy. Good inspection leads to better quality control and fewer errors.

- Inspection systems support factories by finding defects early.

- Quality improves when inspection and control work together.

- Experts can help choose the best system for each inspection need.

For the best results in inspection and quality control, consult with vendors or specialists.

FAQ

What is the main advantage of using a smart camera in industrial automation?

Smart cameras combine image capture and processing in one device. This design reduces system complexity and setup time. Factories benefit from faster inspections and easier integration with existing equipment.

How does lighting affect machine vision inspection accuracy?

Proper lighting improves image clarity and contrast. Good lighting helps the camera detect small defects and measure parts accurately. Poor lighting can cause shadows or glare, making inspection less reliable.

Can smart cameras work in harsh industrial environments?

Yes. Many smart cameras have rugged housings with high IP ratings. These cameras resist dust, water, and impacts. They operate reliably in factories with vibration, temperature changes, or moisture.

What types of inspections can machine vision systems perform?

Machine vision systems check for defects, measure parts, read barcodes, and verify assembly. They also sort products and guide robots. These systems support many industries, including electronics, automotive, and food processing.

Do smart cameras support AI-based inspection?

Yes. Many smart cameras use built-in AI algorithms. These features help detect complex defects, sort products, and adapt to new inspection tasks. AI improves accuracy and reduces false positives.

See Also

Understanding The Role Of Cameras In Machine Vision

A Detailed Overview Of Electronics In Machine Vision

Complete Guide To Machine Vision For Industrial Automation

Exploring Image Processing Techniques In Machine Vision Systems

Comparing Firmware-Based Machine Vision With Traditional Systems