Lighting plays a crucial role in every machine vision application. Bright field illumination delivers uniform lighting that highlights surface features, making it ideal for inspection tasks. Industries such as automotive, consumer electronics, food and beverage, and pharmaceuticals rely on this lighting for quality control and defect detection. The bright field illumination machine vision system enhances productivity and accuracy by using advanced LED lighting technology.

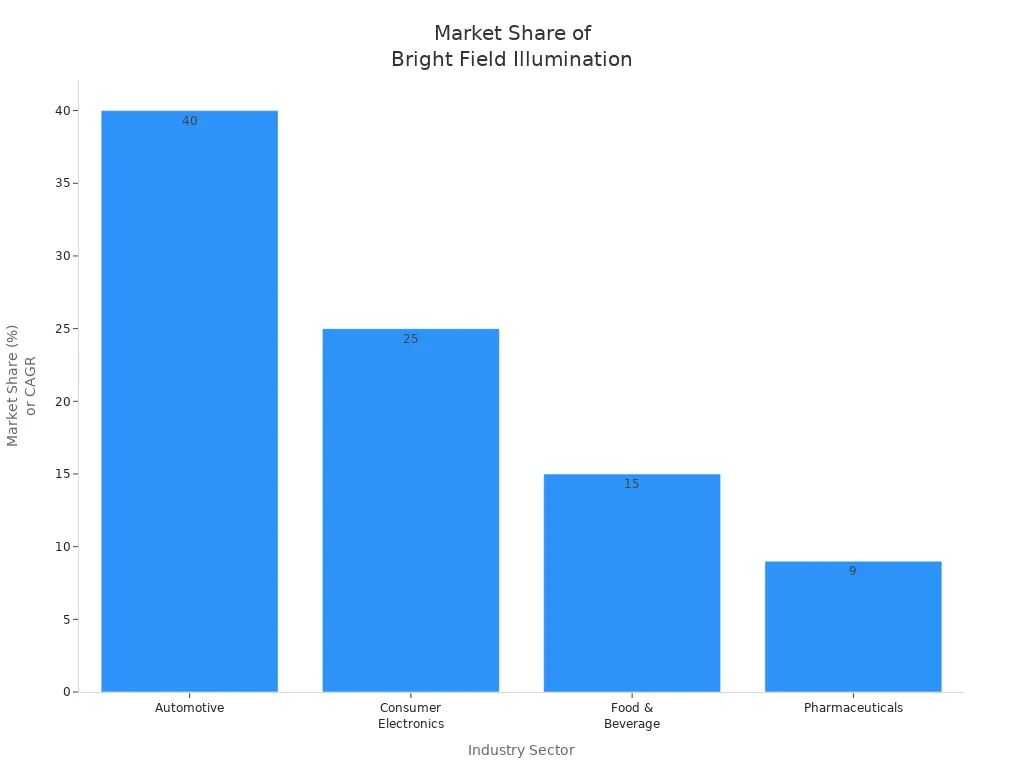

| Industry Sector | Market Share / Growth Indicator | Key Application Details |

|---|---|---|

| Automotive | Largest market share (~40%) | Precise inspection during assembly and quality control |

| Consumer Electronics | Significant share (~25%) | Fault detection in circuit boards, improving reliability |

| Food & Beverage | Notable share (~15%) | Quality assurance and defect detection |

| Pharmaceuticals | Fastest-growing sector (CAGR ~9%) | Automation in production and packaging |

Key Takeaways

- Bright field illumination provides even, direct lighting that highlights surface features, making it ideal for inspecting flat or slightly curved objects.

- This lighting method improves defect detection accuracy in industries like automotive, electronics, food, and pharmaceuticals by creating strong contrast between the object and its background.

- Proper setup, including aligning the light source and camera and choosing the right lighting angle and intensity, is essential for clear, glare-free images.

- Bright field lighting works best on matte or mildly reflective surfaces but may cause glare on highly reflective or rough surfaces, where other lighting methods like dark field may be better.

- Combining bright field illumination with other lighting techniques and adjusting wavelength and ambient light can further enhance inspection accuracy and reliability.

Bright Field Illumination Machine Vision System

What Is Bright Field Lighting

Bright field lighting is a method in which illumination floods the object’s surface directly, allowing the vision system to capture clear images of surface features. This technique uses either full bright field lighting, which provides diffuse, multidirectional light, or partial bright field lighting, which uses directional light from a point source. Full bright field lighting works well for curved or shiny surfaces, while partial bright field lighting enhances contrast and topographic details. The bright field illumination machine vision system relies on this approach to highlight textures, scratches, or dents on flat or slightly curved surfaces. In an illumination machine vision system, bright field lighting stands out because it creates high contrast between the object and its background, making surface imperfections easy to detect.

Core Principles

The core principles of bright field illumination focus on how lighting interacts with the object and the camera. The incidence angle, usually between 45° and 90°, ensures that light reflects directly back to the camera, producing a bright image. Beam directionality affects the visibility of shadows and contrast. Uniformity in illumination is essential for consistent image capture across the entire surface. Adequate light intensity supports proper exposure and a high signal-to-noise ratio. The bright field illumination machine vision system often uses LEDs, halogen lamps, or fluorescent lights as sources. LED illumination has become popular due to its stability and long life. The setup includes aligning the light source and camera at the same angle, which is critical for effective image capture.

| Component | Function | Example Use Case |

|---|---|---|

| Light Sources (LEDs, halogen, fluorescent) | Provide controlled illumination | Surface defect detection |

| Optics | Focus and shape light | Enhance image clarity |

| Sensors | Capture reflected light | Detect scratches or dents |

| Diffusors | Scatter light for uniformity | Inspect shiny surfaces |

| Housings | Protect and direct light | Industrial environments |

When comparing illumination techniques, bright field lighting uses direct or diffuse light to highlight surface details. Dark field illumination, in contrast, uses low-angle lighting to reveal tiny defects by capturing light reflected from edges. Diffuse illumination, also called full bright field lighting, provides even, multidirectional lighting, reducing glare and shadows. The bright field illumination machine vision system excels at inspecting flat, matte, or slightly reflective surfaces. Other illumination techniques, such as dark field or diffuse, may work better for highly reflective or curved objects. Choosing the right lighting technology ensures the vision system delivers accurate and reliable results in machine vision lighting applications.

How It Works

Lighting Setup

A bright field illumination machine vision system uses several lighting setups to achieve clear and consistent results. Most systems place a ring of light around the camera, shining directly onto the object. This setup makes flat, reflective surfaces appear bright and easy to inspect. Full bright field lighting uses dome or on-axis diffuse lights. These lights scatter illumination in many directions, which helps reduce shadows and glare. This method works well for shiny or mixed reflectivity surfaces. Partial bright field lighting uses point sources to create strong contrast and highlight surface details. Coaxial illumination directs light in line with the camera, making flat areas look bright and angled surfaces appear dark. Dome lighting acts like a cloudy sky, spreading light evenly and reducing shadows. Each lighting technology helps the vision system capture high-quality images for defect detection.

Tip: Proper alignment of the light source and camera ensures even illumination and better image capture.

Image Formation

Bright field lighting plays a key role in forming high-quality images in an illumination machine vision system. Directional or diffuse lighting interacts with the object’s surface to create image contrast. Partial bright field lighting, which uses a point source, highlights surface bumps and scratches but may cause bright spots on shiny surfaces. Diffuse bright field lighting, such as dome lights, spreads illumination evenly, reducing glare and making features easier to see. The vision system relies on these lighting methods to capture clear images, which are essential for accurate defect detection. The choice of lighting depends on the object’s surface—flat, textured, or reflective. Good lighting technology ensures the machine vision lighting system produces reliable results.

Advantages and Limits

Bright field illumination offers several strengths for machine vision lighting. It provides even, multi-directional illumination, making it ideal for inspecting flat or slightly curved surfaces. On-axis diffuse lighting enhances features like textures and small dents. Axial diffuse lighting can use glare to reveal unique details, helping with robust defect detection. Partial bright field lighting creates strong contrast and highlights topographic features. However, bright field lighting has limits. It struggles with highly reflective or textured surfaces, often causing glare or bright spots that hide important details. Diffuse lighting needs to be close to the object and may not remove all glare. In these cases, other lighting technology, such as dome or dark field lighting, may work better. The illumination machine vision system must choose the right setup to ensure accurate image capture and reliable inspection.

Applications in Machine Vision

Surface Detection

Bright field lighting plays a key role in surface detection across many industries. This lighting method works best for flat or slightly curved surfaces. It provides strong contrast, which helps machine vision systems spot small scratches, dents, or other surface flaws. In manufacturing, companies use bright field lighting to inspect automotive parts. For example, they check headlamp lenses for scratches and star washers in air brake couplings for dents. The directional lighting from a point source highlights topographic details, making defect detection more accurate.

- Automotive factories use bright field lighting to find scratches on painted panels.

- Machine vision systems combine bright field lighting with high-resolution cameras to improve detection accuracy.

- Factories often use AI to analyze images and catch defects that humans might miss.

Tip: For best results, align the light source and camera carefully. This setup increases accuracy and reduces missed defects.

Bright field lighting stands out when compared to dark field lighting. Dark field works better for finding tiny cracks or particles, but bright field excels at showing larger surface flaws on flat materials.

Print and Web Inspection

Print and web inspection needs clear, even lighting to spot print defects, missing text, or color issues. Bright field lighting provides this uniform illumination, making it easier for machine vision systems to detect problems on labels, packaging, or newspapers. The lighting highlights differences in ink coverage and surface texture, which helps with defect detection and quality assurance.

- Printing companies use bright field lighting to check for smudges, streaks, or faded areas.

- Web inspection systems scan moving materials, such as paper or plastic films, for defects or contamination.

- Bright field lighting ensures high accuracy by reducing shadows and glare.

When compared to other lighting methods, bright field lighting offers better results for flat, matte surfaces. Diffuse lighting can help with glossy materials, but bright field remains the top choice for most print inspection tasks.

Electronics and PCB Detection

Electronics manufacturing relies on accurate detection of faults on printed circuit boards (PCBs). Bright field lighting helps machine vision systems find missing components, soldering defects, or scratches on PCB surfaces. The lighting creates high contrast between the board and its features, which improves detection accuracy.

- Factories use bright field lighting to inspect PCBs for solder bridges, missing pins, or surface contamination.

- The lighting setup often includes ring lights or coaxial lights to provide even illumination.

- Machine vision systems use these images to guide robots during assembly and package inspection.

Bright field lighting works well for flat PCB surfaces. For highly reflective or complex boards, combining bright field with other lighting methods, such as dark field, can improve detection.

Food and Medical Uses

Bright field lighting supports detection and inspection in food and medical industries. In food processing, machine vision systems use this lighting to check for contamination, surface defects, or missing items on conveyor belts. The lighting makes it easier to spot foreign objects or damaged products, which helps maintain safety and quality.

In medical device inspection, bright field illumination provides bright, uniform lighting that reveals surface structures and defects, such as scratches or contamination. Advanced optical inspection systems use LED ring lights to reduce glare and highlight surface details. This approach allows for fast and reliable detection of macro defects and surface features, which is critical for quality control. Combining bright field images with other lighting techniques can further improve detection accuracy and surface analysis.

Note: Bright field lighting is essential for contamination detection in both food and medical device inspection. It helps companies meet strict safety standards and ensures product reliability.

| Industry | Application Example | Lighting Benefit |

|---|---|---|

| Food Processing | Contamination detection on belts | Uniform lighting for clear images |

| Medical Devices | Surface defect detection | Bright, glare-free illumination |

Bright field lighting remains a top choice for machine vision applications that require high accuracy, fast detection, and reliable inspection results.

Best Practices for Illumination Machine Vision System

When to Use Bright Field

Selecting the right illumination method is important for inspection tasks. Bright field lighting works best when the surface is flat, slightly curved, or has mixed reflectivity. This method provides strong contrast, which helps the system spot scratches, dents, or missing material. Inspectors should look at the surface’s reflectivity, flatness, and texture before choosing the lighting. For shiny or curved surfaces, diffuse dome lights offer even illumination. On flat, textured surfaces, on-axis diffuse lights give clear results. Directional bright field lighting can highlight topographic details, but it may cause glare on very shiny surfaces. Matching the light’s color to the camera sensor improves accuracy. Inspectors should also consider the inspection environment, such as working distance and ambient light. No single lighting method fits every situation, so flexibility is key for an optimal lighting solution.

Setup Tips

Proper setup ensures high accuracy in machine vision systems.

- Place dome or on-axis diffuse lights close to the object for even illumination on shiny or curved surfaces.

- Use partial bright field lighting to enhance surface details, but avoid direct on-axis use with specular surfaces to prevent hotspots.

- Adjust the lighting angle and intensity to maximize contrast and reduce glare.

- Choose the right wavelength to make features stand out. For example, blue light can help separate silver from copper.

- Check for ambient light contamination and adjust the setup to block unwanted light.

- Consider the object’s movement and speed during inspection.

- Test different lighting setups to find the most effective lighting solution for each application.

Tip: Always analyze how the sample interacts with the illumination. This step helps improve accuracy and reliability.

Comparing Lighting Methods

Choosing the best illumination method depends on several factors. Inspectors compare lighting based on contrast, inspection environment, and how the sample interacts with the light. Bright field lighting is versatile and works well for general inspections. Diffuse illumination is useful for reflective or textured surfaces. Dark field lighting highlights small defects by removing glare. Sometimes, combining bright field and dark field illumination increases accuracy and defect detection rates. The table below shows key criteria for comparing lighting methods:

| Criteria | Impact on Lighting Choice |

|---|---|

| Contrast | Highlights edges, textures, or markings for better accuracy |

| Inspection Environment | Considers ambient light, part speed, and exposure time |

| Sample/Light Interaction | Reflectivity, texture, and absorption affect illumination effectiveness |

| Lighting Geometry | Different setups offer unique strengths and weaknesses |

| Spectral Content | Wavelength choice can enhance or reveal specific features |

| Physical Constraints | Fixture and camera placement may limit lighting options |

Note: Maximizing contrast on features of interest and ensuring robustness against changes in part presentation are key to achieving high accuracy in inspection.

Bright field lighting supports surface inspection, edge detection, and quality control in industries such as automotive, electronics, and pharmaceuticals.

- Full bright field lighting, including dome and on-axis diffuse lights, works well for shiny or curved surfaces.

- Directional lighting enhances contrast on flat objects.

- Ring, bar, and dome lights each offer unique benefits for different inspection needs.

To optimize lighting, select the right wavelength, control ambient light, and use strobed lighting for moving parts.

- Assess the inspection environment and sample surface.

- Choose lighting geometry and intensity based on part shape and reflectivity.

- Ensure consistent part placement for reliable results.

Evaluate inspection needs and explore bright field illumination solutions to improve machine vision accuracy.

FAQ

What is the main benefit of bright field illumination in machine vision?

Bright field illumination helps machine vision systems see surface details clearly. It creates strong contrast between features and the background. This makes it easier to find scratches, dents, or missing parts.

When should a company avoid using bright field lighting?

Companies should avoid bright field lighting for highly reflective or rough surfaces. This lighting can cause glare or hide small defects. Dark field or dome lighting may work better in these cases.

Which industries use bright field illumination the most?

| Industry | Common Use |

|---|---|

| Automotive | Surface inspection |

| Electronics | PCB defect detection |

| Food & Beverage | Contamination checks |

| Pharmaceuticals | Packaging inspection |

How does bright field lighting compare to dark field lighting?

Bright field lighting works best for flat surfaces and large defects. Dark field lighting highlights small scratches or particles. Each method has strengths for different inspection needs.

See Also

Why Proper Lighting Is Essential For Machine Vision Success

Understanding The Role Of Cameras In Vision Systems

The Impact Of Structured Light On Machine Vision Accuracy

How Optical Filters Improve Performance In Machine Vision

Comparing Firmware-Based And Traditional Machine Vision Systems