A frame rate machine vision system depends on fps to deliver accurate results in demanding industrial environments. High frame rate enables a machine vision system to capture rapid events without motion blur, ensuring precise detection and inspection. In many factories, fps determines whether a system can track or inspect moving parts effectively.

- High-speed manufacturing lines, such as electronic component assembly or product inspection on conveyor belts, require high frame rate to capture every detail.

- Robotic pick and place operations, barcode scanning on moving items, and sorting tasks rely on fps for real-time accuracy.

- Fast-moving objects like fan blades or turbines demand high frame rate to avoid blurred images.

- Embedded vision systems in automation use fps for clear, actionable data.

Frame rate plays a vital role in every machine vision system, directly impacting the quality of information captured and processed.

Key Takeaways

- High frame rate helps machine vision systems capture fast-moving objects clearly, reducing motion blur and improving inspection accuracy.

- Balancing frame rate and image resolution is essential; higher frame rates may require lower resolution to maintain speed and image quality.

- Global shutter sensors support higher frame rates without distortion, making them ideal for fast industrial tasks.

- Machine vision systems with high frame rates enable real-time detection, quality control, and precise robotic automation.

- Choosing the right frame rate depends on object speed, lighting, and system capabilities to ensure accurate and efficient operation.

Frame Rate Basics

What Is FPS?

In industrial machine vision, fps stands for frames per second. This value shows how many images an image sensor captures every second. For example, if an image sensor processes 100 images in 2 seconds, the fps equals 50. High fps allows a machine vision system to track fast-moving objects and avoid missing important details. In applications like Automatic Number Plate Recognition, higher fps improves accuracy by capturing more frames per second, which helps identify speeding vehicles in real time. The image sensor must keep up with the speed of the production line to ensure no detail is lost.

Frame Rate vs. Resolution

Frame rate and high resolution work together but often compete for system resources. When an image sensor captures images at high resolution, each frame contains more data. This extra data can slow down the fps because the system needs more time to process each image. If a user increases the frame rate, the image sensor may need to lower the resolution to keep up. High resolution improves image quality, but too much data can reduce the number of frames per second. Machine vision engineers must balance frame rate and high resolution to get the best image quality for their application. Good lighting and strong hardware help maintain both high resolution and high fps.

Shutter Speed and Exposure

Shutter speed and exposure time control how long an image sensor collects light for each frame. Shorter exposure times reduce motion blur, which is important for high fps and clear image quality. In rolling shutter image sensors, each row of pixels exposes at a slightly different time, which can cause distortion in fast-moving scenes. Global shutter image sensors expose all pixels at once, preventing this distortion and supporting high fps. The choice between rolling and global shutter affects the maximum frame rate and image quality. For high-speed tasks, global shutter image sensors provide the best results.

High Frame Rate in Machine Vision

Real-Time Detection

High frame rate plays a crucial role in real-time detection tasks within industrial environments. A machine vision system with high fps can capture fast-moving objects with short exposure times, which reduces motion blur and improves image clarity. This capability is essential for dynamic inspection scenarios, where products move quickly along production lines. High frame rate cameras enable immediate detection and rapid response to defects, misalignments, or other issues. This quick feedback helps maintain production quality and reduces downtime.

Many automated industrial applications rely on high frame rate for accurate and fast imaging. For example, robotic arms and pick-and-place robots use high fps to sort objects and inspect products in real time. Technical features such as global shutter, strobe function, and external triggers help minimize motion artifacts and synchronize image capture with fast-moving items. These features ensure that the machine vision system delivers reliable results even in challenging conditions.

Tip: High frame rate cameras can transfer data quickly to centralized systems for real-time analysis and decision-making. This process ensures consistent product quality and supports efficient manufacturing workflows.

Fast-Moving Objects

Industrial settings often require the inspection and tracking of fast-moving objects. High frame rate allows a machine vision system to capture more images per second, making it possible to analyze motion and detect defects that would otherwise go unnoticed. Applications such as quality control, optical inspection, and motion analysis depend on high fps to provide detailed visual feedback.

- Industrial robotic arms use high frame rate cameras for precise motion control and real-time image processing.

- Quality control systems rely on high fps for defect detection, pattern recognition, and slow-motion analysis of moving parts.

- Machine vision systems in industries like aerospace, automotive, and sports use high-speed cameras to analyze motion trajectories and patterns.

A high frame rate machine vision system often uses a region of interest (ROI) to increase fps. By reducing the ROI, the camera processes fewer pixels, which decreases the data load and allows for faster image capture. In CMOS sensors, selecting a smaller ROI means fewer pixels are digitized, enabling the camera to operate at higher frame rates. Halving the sensor size can double the fps, showing a direct relationship between image area and speed. Reducing the number of sensor lines (rows) also increases frame rates, although this may limit the field of view. For applications focused on small, fast-moving targets, this trade-off is often acceptable.

Embedded vision systems benefit from high frame rate by delivering real-time video processing and accurate tracking. These systems support tasks such as barcode scanning, product sorting, and quality assurance, where every frame counts. Real-time processing ensures that the machine vision system can keep up with the demands of modern manufacturing.

Note: Implementing high frame rate in industrial environments presents challenges. Teams must address issues such as data quality, image preprocessing, and system integration. Proper synchronization among cameras, sensors, and actuators is essential for reliable operation. Selecting the right hardware and training employees to interpret data also contribute to successful adoption.

Factors Affecting Frame Rate

Sensor and ROI

The type of image sensor plays a major role in achieving high frame rate in any machine vision system. Global shutter image sensors, such as Onsemi’s PYTHON family, capture all pixels at once. This design eliminates motion artifacts and distortion, which often occur with rolling shutter sensors. These global shutter sensors support fps rates above 800 at lower resolutions, making them ideal for fast-moving industrial tasks. The pixel size, usually around 4.5 to 4.8 microns, helps balance sensitivity and speed. Modern sensor technology, like global shutter CMOS, allows for 1080p video at 120 fps with low noise. Some advanced sensors, such as SWIR detectors, can reach 1500 Hz, supporting even the most demanding applications.

Region of Interest (ROI) settings also affect fps. By selecting a smaller ROI, the image sensor processes fewer pixels per frame. This reduction increases fps because the camera reads less data. For example, halving the ROI can nearly double the fps. This method works well for applications that only need to monitor a specific area, such as tracking a single part on a conveyor belt.

Bandwidth and Processing

Data bandwidth limits how much image data a machine vision system can transmit each second. If the bandwidth is too low, the system must lower either the fps or the high resolution to keep up. In GigE systems, the standard bandwidth is about 120MB/s. Without enough bandwidth, designers may need to add more network interface cards, which increases cost and complexity.

- Lossless compression helps by shrinking image data before transmission. This process can boost maximum fps by up to 70% without losing image quality.

- Multiple cameras can share a single network card when using compression, keeping fps high and reducing hardware needs.

- When three 5MP cameras run at different fps, compression allows two to share one card, while the third maintains full resolution and high frame rate.

Efficient data processing also matters. Faster CPUs and optimized software help the system handle high fps without lag.

System Optimization

System optimization ensures the machine vision system reaches its highest possible fps. Engineers must consider environmental and operational factors. Dust, vibration, and heat can lower image quality, forcing the image sensor to use longer exposure times and reducing fps. Lighting conditions must match the camera’s sensitivity. Poor lighting requires longer exposures, which limits fps. Fast object motion needs short exposures and intense lighting to avoid blur.

| Factor | Impact on fps |

|---|---|

| Dust/Vibration | Reduces image quality, lowers fps |

| Lighting | Poor lighting lowers fps |

| Object Speed | Faster objects need higher fps |

| Sensor Characteristics | High dynamic range may lower fps |

| Interface Bandwidth | Limits maximum fps |

Engineers must match optics, camera placement, and interface type to the image sensor. Proper alignment and stable mounting help maintain high frame rate. Advances in sensor technology, such as improved CMOS sensors, have made it easier to achieve high fps with less noise and better power efficiency. These improvements allow the machine vision system to capture fast-moving objects with clear images and minimal blur.

Tip: Regular maintenance and calibration help keep the system running at peak fps, even in harsh industrial environments.

Applications of Frame Rate Machine Vision System

Quality Control

A frame rate machine vision system plays a key role in quality control across many industries. High frame rate cameras capture products moving quickly on conveyor belts, allowing the machine vision system to inspect each item without missing defects. For example, in food processing, cameras running at 120 fps can spot damaged packaging or foreign objects before products leave the factory. High fps ensures that even small flaws are visible, improving image quality and reducing waste. Many computer vision applications in quality control rely on high frame rate to deliver fast, accurate results. When the system captures more frames per second, it increases the chance of detecting short-lived defects that might appear only for a split second.

Robotics and Automation

Robotics and automation depend on high frame rate for real-time feedback and precise control. In manufacturing, robots use machine vision systems operating at 60 fps or higher to guide pick-and-place tasks, weld seams, or assemble parts. High fps provides the visual data needed for robots to adjust their movements instantly. When the frame rate matches the speed of the production line, the system can detect and correct errors before they cause problems.

- High frame rate vision systems give robots real-time feedback for navigation and interaction.

- Synchronizing fps with production speed ensures no defect goes unnoticed.

- Vision-guided robots improve pose accuracy and compensate for motion errors.

An experiment with a robotic machining platform showed that real-time visual feedback from a binocular vision sensor, combined with advanced control, improved both speed and precision. This approach helped robots drill and mill with greater accuracy, showing the value of high fps in computer vision applications.

Tip: Improving robot motion quality through calibration and vision-guided feedback boosts both speed and reliability in automated tasks.

High-Speed Analysis

High-speed analysis uses high frame rate to study fast events in detail. In sports technology, cameras running at 500 fps or more help coaches analyze an athlete’s movement. In electronics manufacturing, engineers use high fps to monitor soldering processes and catch defects that happen in milliseconds. High frame rate machine vision systems also support scientific research, where capturing every frame is critical for understanding rapid changes. By increasing fps, these systems provide clearer images and more data for analysis, leading to better decisions and improved outcomes.

| Application Area | Typical fps Range | Benefit of High Frame Rate |

|---|---|---|

| Quality Control | 60–240 | Detects fast defects, improves yield |

| Robotics/Automation | 60–120 | Real-time feedback, precise control |

| High-Speed Analysis | 250–1000+ | Captures rapid events, detailed study |

Choosing FPS for Your Machine Vision System

Assessing Needs

Selecting the right fps for a machine vision system starts with a clear understanding of the application’s requirements. Engineers must evaluate several factors before deciding on the optimal frame rate.

- Resolution: Higher resolution provides more detail but can reduce fps due to increased data.

- Sensor size: Larger sensors capture a wider field of view, which may impact the required fps.

- Frame rate and exposure time: Fast-moving objects need higher fps and shorter exposure times to avoid motion blur.

- Lighting conditions: Poor lighting may require longer exposures, which can lower fps.

- Connectivity options: The system must support the data rates needed for high fps.

- Camera features: Functions like autofocus and image stabilization can affect performance and suitable fps.

- Cost considerations: Higher fps often means higher costs, so balancing performance and budget is essential.

Engineers should also consider the speed of the objects being inspected. Fast-moving items require cameras with higher fps, often using global shutter technology. Stationary or slow-moving objects can be captured with lower fps, sometimes with rolling shutter cameras. The type of image sensor and the required image quality both influence the final choice.

Tip: Always match the fps to the production line speed and the smallest defect size that must be detected.

Calculating Object Speed

Understanding object speed is critical for setting the correct fps. The faster an object moves, the higher the fps required to capture clear images without blur. Engineers can use a simple calculation to estimate the minimum fps needed:

Minimum fps = (Object speed per second) / (Maximum allowable movement per frame)

For example, if a conveyor moves at 1 meter per second and the smallest feature to detect is 100 microns, the object should move less than 10 microns during each frame. This means the exposure time must be less than 10 milliseconds, which translates to at least 100 fps. Shorter exposure times reduce motion blur but may require stronger lighting.

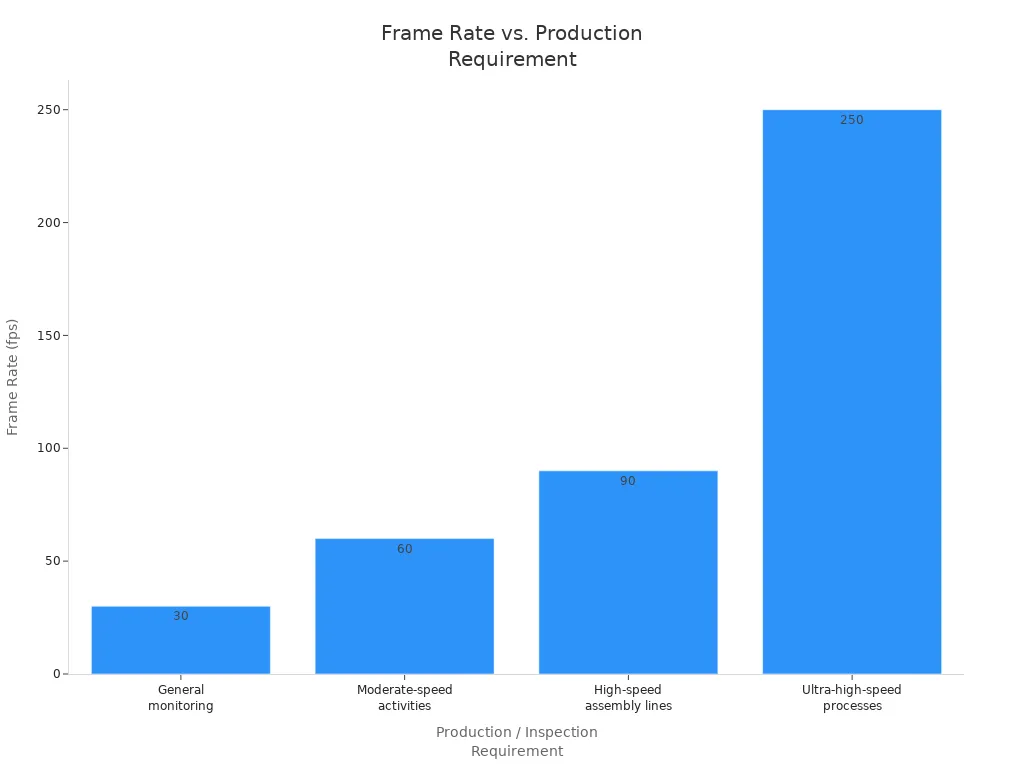

The following table shows how different fps values align with production speeds and inspection needs:

| Frame Rate (fps) | Production Speed / Inspection Requirement | Use Case Example | Benefits | Trade-offs |

|---|---|---|---|---|

| 30 fps | General monitoring, low-speed processes | Overall production floor monitoring | Balances image clarity with manageable bandwidth and storage | Limited for high-speed or detailed motion capture |

| 60 fps | Moderate-speed activities like bottling and packaging | Bottling plant monitoring for speed and precision | Improved motion clarity and better fault detection | Requires more bandwidth and storage |

| 90 fps | High-speed assembly lines requiring precision | Monitoring fast, repetitive machine parts | Captures rapid movements with greater detail | High data capacity needed, overkill for general use |

| 250 fps | Ultra-high-speed specialized processes | Specialized high-speed production and robotic assembly | Captures ultra-fast motion accurately | Very high data demands, specialized use only |

Note: Higher fps reduces motion blur but increases data storage and processing requirements. Engineers must ensure the system infrastructure can handle the chosen fps.

Balancing Performance

Balancing performance in a frame rate machine vision system involves trade-offs between image quality, speed, and cost. Engineers must weigh the benefits of higher fps against the limitations of bandwidth, storage, and budget. Reducing image resolution can increase fps, but may sacrifice detail. Shorter exposure times help capture fast motion, but require better lighting.

Key points to consider:

- High fps improves defect detection and tracking but demands more from the system’s hardware.

- Lower fps reduces data load but may miss fast events or introduce motion blur.

- The choice of shutter type matters. Global shutter cameras support higher fps and work best for fast-moving objects. Rolling shutter cameras suit slower applications.

- Environmental factors, such as lighting and vibration, can affect the achievable fps and image quality.

Engineers should regularly review system performance as production speeds or inspection requirements change. Adjusting fps, resolution, or lighting can help maintain optimal results. Consulting technical resources or camera manufacturers can provide guidance for complex scenarios.

⚡ Alert: Never select fps in isolation. Always consider the entire system, including the image sensor, lighting, and processing capabilities, to achieve the best balance for your application.

Matching frame rate to each application ensures a machine vision system meets accuracy and speed requirements. Metrology and inspection tasks demand different frame rates and resolutions, from micron-scale solar panels to large electronics. High-speed cameras and flexible multi-camera setups help detect tiny defects and track fast-moving parts.

Regular evaluation and testing under real conditions support ongoing optimization. Industry standards like GigE Vision, USB3 Vision, and GenICam offer guidance. Consulting vision experts helps address complex frame rate choices and future needs.

FAQ

What is the ideal frame rate for industrial inspection?

The ideal frame rate depends on object speed and inspection detail. Most production lines use 60–120 fps. High-speed applications may require 250 fps or more. Engineers should match frame rate to production needs for best results.

How does frame rate affect image quality?

Higher frame rates reduce motion blur and capture fast events. However, increasing frame rate may lower resolution or require more lighting. Engineers must balance frame rate, resolution, and lighting to maintain clear images.

Can a machine vision system upgrade its frame rate later?

Many systems allow frame rate adjustments through software or hardware upgrades. Upgrading sensors, processors, or network interfaces can increase fps. Always check compatibility with existing equipment before upgrading.

Does higher frame rate increase data storage needs?

Yes. Higher frame rates generate more images per second. This increase requires more storage and faster data processing. Engineers should plan for larger storage capacity and robust data management.

Tip: Regularly review system performance and storage to avoid bottlenecks as frame rate increases.

See Also

Understanding Frame Rate Effects On Machine Vision Accuracy

Essential Frame Grabbers Used In Advanced Vision Systems

Comparing Firmware-Based Vision With Conventional Systems

How Optical Filters Enhance Performance In Vision Technology