Image resolution plays a vital role in every machine vision system. The right resolution allows a camera to capture detailed images, helping machine vision systems spot even the smallest defects. Research shows that high-resolution 2D imaging improves defect detection, but it can slow processing if not balanced with the system’s speed. In industrial settings, richer pixel data from better image resolution leads to more accurate results.

| Inspection Method | Accuracy/Impact |

|---|---|

| AI-powered defect detection | 95–98% accuracy |

| Automated visual inspection | Defect rates reduced by up to 80% |

| Inspection error reduction | Over 90% lower than manual inspection |

| Human error rate reduction | From 25% down to under 2% |

Choosing the right image resolution machine vision system ensures that cameras deliver the precision needed for each application.

Key Takeaways

- Choose the right image resolution based on the smallest feature you need to detect to ensure accurate defect detection without slowing down your system.

- Balance camera resolution with processing speed and cost to keep your machine vision system efficient and affordable.

- Use high-quality sensors, lenses, and proper lighting together to capture clear, sharp images that improve inspection accuracy.

- Regularly calibrate your machine vision system to maintain measurement accuracy and reliable performance over time.

- Avoid over-specifying resolution or using poor lenses, as these can increase costs and reduce image quality without improving results.

Image Resolution in Machine Vision Systems

What Is Image Resolution?

Image resolution in a machine vision system describes how many pixels make up an image. Most systems express resolution as width by height, such as 1920 x 1080 pixels. This number shows how much detail the image sensor can capture. A higher resolution means the camera collects more pixel data, which helps with tasks like defect detection and quality control.

- The total pixel count, often called megapixels, is another way to describe resolution. For example, a 2-megapixel sensor has about 2 million pixels.

- Pixel size also matters. Larger pixels gather more light, which can improve image quality, especially in low-light conditions.

- The field of view, or how much area the camera sees, works with resolution to decide how small a feature the system can detect.

Selecting the right image resolution machine vision system involves balancing detail, speed, and cost. In industrial image processing, the right resolution ensures accurate image analysis and reliable results.

Resolution and Image Quality

Resolution and image quality connect closely, but they are not the same. A higher resolution allows the machine vision system to capture finer details, which is important for precise image analysis. However, image quality also depends on the sensor type, pixel size, and lighting.

| Aspect | Effect of Higher Pixel Count | Effect of Pixel Size (Large vs Small) |

|---|---|---|

| Detail Capture | More detail in images | Larger pixels improve image quality, especially in low light |

| Sensitivity | Smaller pixels increase resolution | Larger pixels boost sensitivity and reduce noise |

| Optical Compatibility | — | Sensor and optics must match for best results |

| Trade-offs | More pixels may mean smaller pixel size | Balance between sensitivity, resolution, and cost |

A high resolution sensor with small pixels may need strong lighting to avoid noisy images. Good image quality in an image processing machine vision system also relies on high-quality optics and proper sensor alignment. In industrial image processing, the right combination of sensor, optics, and lighting leads to clear, sharp images.

Common Misconceptions

Many believe that higher resolution always means better results in a machine vision system. This is not true.

- Resolution must fit the application’s needs. Too much resolution can slow down image processing machine vision system performance and increase storage needs.

- Image quality depends on more than just resolution. Sensor size, pixel size, lighting, and optics all play a role.

- In some cases, increasing resolution does not improve results. For example, if the dataset lacks variety or the system faces overfitting, better resolution will not help.

- Effective machine vision systems balance resolution with speed, sensor performance, and the demands of image analysis.

Tip: Always consider the entire image resolution machine vision system, not just the sensor’s pixel count, to achieve the best image quality and reliable results.

Resolution and Performance

Accuracy and Defect Detection

Camera resolution directly shapes the ability of a machine vision system to detect small defects and measure features with precision. In manufacturing, the smallest defect a camera can find depends on how many pixels cover the area under inspection. For example, in woven fabric inspection, researchers found that one pixel represented about 0.0934 mm. Defects needed to cover at least five pixels, or about 0.5 mm, to be reliably detected. This means that camera resolution, defined by the number of pixels and their size, sets a clear limit on the smallest defects a system can catch.

A higher camera resolution allows the system to spot tinier defects, which is critical for quality control in industries like electronics, automotive, and pharmaceuticals. The formula for minimum detectable defect size is:

Minimum detectable size = (Field of view × Minimum pixel count for detection) ÷ Number of pixels in the sensor's Y direction

For instance, with a camera that has 1200 pixels in the Y direction and a 60 mm field of view, a defect must cover at least two pixels to be detected. The smallest detectable defect would then be 0.1 mm. This calculation shows that increasing camera resolution or narrowing the field of view lets the system find even smaller defects.

Measurement accuracy in quality control also depends on camera resolution. More pixels mean the system can measure features more precisely. However, accuracy relies on repeatability. The system must produce the same results every time before it can be considered accurate. Calibration is important because pixel sizes may differ across the sensor, and digitization does not always line up perfectly with object edges. The relationship between accuracy, repeatability, and camera resolution is complex, but understanding it helps engineers design better machine vision systems.

Note: A machine vision system with high resolution improves defect detection, but only if the rest of the system—like lighting and optics—matches the camera’s capabilities.

Application Suitability

Different manufacturing applications require different levels of camera resolution and image quality. For simple tasks like barcode reading or basic visual inspection, a VGA camera (640 x 480 pixels) often provides enough detail. These cameras work well for large features and fast processing. For more demanding tasks, such as detecting tiny cracks in electronics or inspecting printed circuit boards, cameras with 2 to 21 megapixels are common. These high resolution cameras capture more detail, making them ideal for finding small defects and ensuring product quality.

The table below shows how camera resolution impacts various machine vision applications:

| Application | Typical Camera Resolution | Impact on Quality and Defect Detection |

|---|---|---|

| Barcode Scanning | VGA (640 x 480) | Fast, low detail needed, large features |

| OCR (Optical Character Recognition) | 2-5 MP | Higher detail for small text, better accuracy |

| Electronics Inspection | 5-21 MP | Finds tiny defects, ensures high quality |

| Surface Defect Detection | 2-12 MP | Detects small cracks, scratches, or pits |

| AI-based Visual Inspection | 8-21 MP | Needs high resolution for texture/context |

Selecting the right camera resolution for a machine vision system involves trade-offs. Higher resolution improves defect detection and measurement accuracy, but it also increases the amount of image data. This extra data slows down processing and requires more storage. For example, AI-based inspection systems often need 5-10 pixels per smallest feature, while traditional systems may need only 3 pixels. More pixels mean better accuracy, but also more demand on the system.

| Aspect | Impact of Higher Camera Resolution | Trade-offs and Solutions |

|---|---|---|

| Detection Accuracy | Improves with more pixels per defect | Must balance with speed and throughput |

| Processing Load | Increases, slowing down inspection | Use Region of Interest (ROI) to focus |

| Storage/Bandwidth | Requires more capacity | Optimize hardware and data management |

| Frame Rate | May decrease due to larger images | ROI and faster hardware help maintain speed |

Manufacturers often use optimization techniques to balance these factors. For example, they may process only regions of interest, use faster processors, or compress images. In automation, speed is crucial for keeping up with production lines. In medical imaging, accuracy takes priority, even if it slows down inspection. Each machine vision system must match its camera resolution and image quality to the needs of the application.

Tip: Always match camera resolution to the smallest defect size you need to detect. Avoid over-specifying, as too much resolution can slow down your machine vision system and increase costs without improving quality.

Key Factors in Image Resolution Machine Vision System

Sensor and Pixel Count

The sensor is the heart of every camera in an image processing machine vision system. The type of sensor, such as CCD or CMOS, affects camera resolution and image sensor performance. CMOS sensors now dominate industrial image processing because they use less power, work faster, and cost less. CCD sensors still offer better image quality in low-light settings, but they are slower and more expensive. The pixel count, or the number of pixels on the image sensor, sets the maximum camera resolution. More pixels mean higher camera resolution and finer detail in image capture. Pixel size also matters. Smaller pixels increase camera resolution and allow high-resolution cameras to detect tiny features. However, smaller pixels can lower sensitivity and dynamic range. Larger pixels collect more light, which helps in low-light conditions. Modern image sensors use new designs to balance pixel size, camera resolution, and sensitivity for the best results in industrial image processing.

Optics and Field of View

The lens and field of view play a big role in camera resolution. The lens must match the image sensor size and the area the camera needs to see. A wide field of view spreads pixels over a larger area, which lowers pixel density and camera resolution. A narrow field of view focuses pixels on a smaller area, increasing detail. The working distance, or how far the camera is from the object, also affects focus and sharpness. For example, moderate focal length lenses need a working distance of about 100 mm, while longer lenses may need up to 1000 mm. Macro lenses work well for close-up image analysis. The right lens choice ensures that high-resolution cameras use all their pixels for clear, sharp images.

Lighting and Environment

Lighting and environmental factors shape the effective camera resolution in any machine vision system. Good lighting makes features stand out and improves camera resolution. Different lighting techniques, like diffuse or dark field lighting, help reduce glare and highlight defects. The camera sensor’s sensitivity and shutter speed must match the lighting to avoid motion blur and keep image quality high. Environmental factors, such as dust, temperature, and vibrations, can lower camera resolution by affecting lighting and image sensor performance. Using shields, filters, and vibration-resistant mounts helps protect the camera and lighting. Regular cleaning and proper enclosures keep the system working well. Advanced lighting, like LED pulsing and multispectral lights, boosts camera resolution and helps high-resolution cameras find small defects during image analysis.

Tip: Always match the sensor, lens, and lighting to the needs of your application to get the best camera resolution and reliable results.

Choosing Resolution for Machine Vision

Calculating Required Resolution

Selecting the right camera resolution for a machine vision system starts with understanding the smallest feature that needs detection in manufacturing. Engineers use a step-by-step approach to ensure the camera captures enough detail for reliable inspection.

- Identify the smallest feature size that must be detected or measured.

- Decide how many pixels should cover this feature. Most experts recommend at least two to four pixels across the smallest feature for clear detection.

- Calculate the spatial resolution by dividing the feature size by the number of pixels needed. For example, if a 0.25 mm feature requires four pixels, the spatial resolution becomes 0.0625 mm per pixel.

- Determine the field of view (FOV) required to cover the inspection area. The FOV depends on the sensor size, working distance, and lens focal length. The formula is:

FOV = (Sensor Size × Working Distance) / Focal Length - Calculate the required camera resolution along each axis by dividing the FOV by the spatial resolution. For a 40 mm FOV and 0.0625 mm/pixel, the camera needs at least 640 pixels in that direction.

- Multiply the required pixels for both width and height to find the minimum total camera resolution.

Industry professionals often use another formula for quick estimation:

Sensor resolution = (FOV / size of smallest feature) × 2

This factor of two ensures the camera resolution is high enough for reliable detection. In manufacturing, this method helps engineers choose a camera that matches the inspection task without overspending.

Professionals also relate the pixel size to the measurement tolerance. They use a rule of thumb: the pixel size should be about one-tenth of the tolerance band. This ensures the camera resolution supports repeatable and accurate measurements. Advanced algorithms, such as edge analysis, can sometimes improve accuracy beyond the sensor’s spatial resolution, but these methods require careful validation.

Tip: Always specify the camera resolution based on the smallest feature and the required field of view. Avoid guessing or using only the highest available resolution.

Balancing Speed and Cost

Choosing higher camera resolution improves defect detection in manufacturing, but it also increases system complexity and cost. High-resolution cameras generate larger image files, which require more processing power and storage. This can slow down real-time processing, especially in fast-paced automation environments.

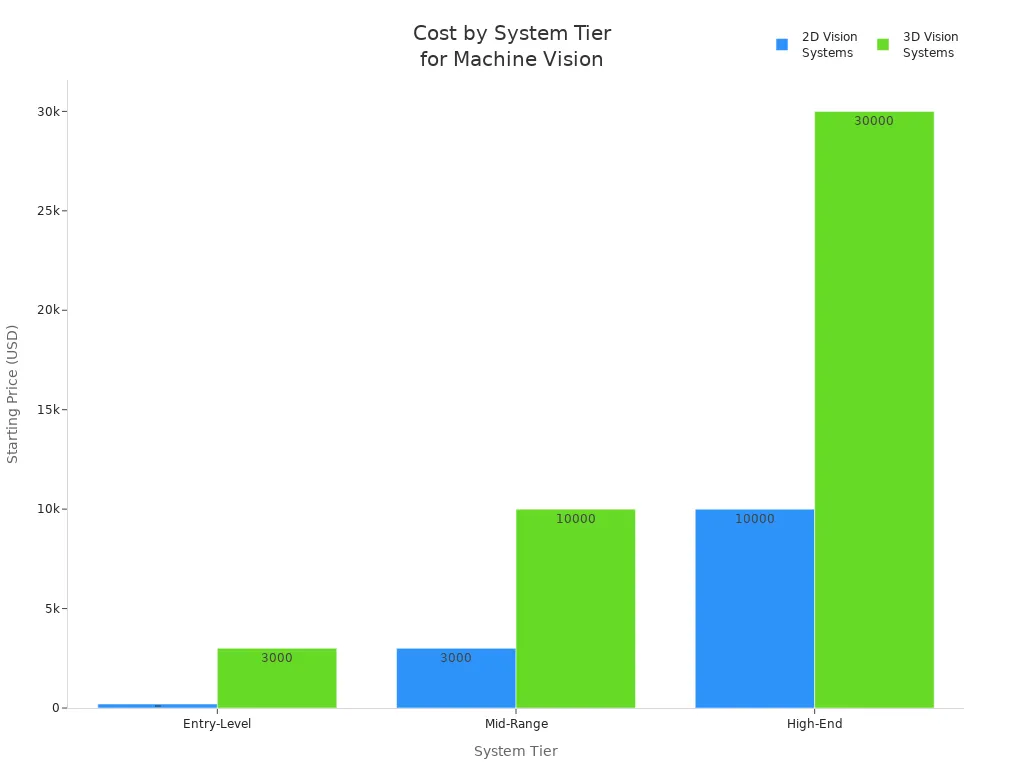

| System Type | Tier | Price Range (USD) | Description and Cost Implications |

|---|---|---|---|

| 2D Vision Systems | Entry-Level | $200 – $3,000 | Basic resolution, suitable for simple tasks, lowest cost entry point |

| Mid-Range | $3,000 – $10,000 | Higher resolution and speed, suitable for more complex applications | |

| High-End | $10,000 – $25,000+ | Ultra-high resolution, advanced software, high-speed automation lines | |

| 3D Vision Systems | Entry-Level | $3,000 – $10,000 | Standard resolution, basic measurements and inspections, higher base cost than 2D entry-level |

| Mid-Range | $10,000 – $30,000 | Higher resolution and processing power, detailed inspections, precise robot guidance | |

| High-End | $30,000 – $60,000+ | Top-of-the-line resolution, rapid processing, complex applications |

Development costs also rise with high-resolution cameras. User-friendly software and integrated lighting can reduce setup time and hardware expenses. Maintenance costs increase if the system requires frequent calibration or if cheaper cameras fail more often. Investing in industrial-grade cameras with advanced calibration tools can lower long-term costs by reducing downtime.

Increasing camera resolution also affects system speed. High-resolution images demand more processing power. Traditional interpolation methods process images quickly but may lose detail. Deep learning methods provide sharper images but require powerful hardware and longer processing times. Some advanced algorithms, like Neural Explicit Representation, speed up image rescaling without sacrificing quality. In manufacturing, engineers often optimize lighting and hardware to maintain speed and image quality.

Note: Balancing camera resolution, speed, and cost ensures the machine vision system meets manufacturing needs without overspending or slowing production.

Avoiding Common Pitfalls

Many manufacturing teams make mistakes when choosing camera resolution for machine vision. Over-specifying resolution is a common error. Selecting a camera with more pixels than needed increases costs and slows down real-time processing without improving accuracy. Underestimating the importance of lens quality also leads to poor results. Even the best high-resolution camera cannot deliver sharp images if the lens introduces distortion.

Common lens issues include:

- Barrel distortion, which curves straight lines outward and reduces measurement accuracy.

- Pincushion distortion, which bends lines inward and complicates calibration.

- Perspective distortion, which changes how objects appear and affects spatial analysis.

Poor lens quality spreads the camera’s resolution over a wide field of view, lowering pixel density and detail. This can cause the system to miss small defects or fail to identify objects at a distance. Calibration and correction techniques help reduce these distortions. Using the right lens and regular calibration ensures the camera resolution delivers reliable results.

Calibration techniques improve measurement accuracy in high-resolution systems. Engineers use checkerboard patterns to map 3D world points to 2D image coordinates. They estimate both intrinsic parameters (like focal length and lens distortion) and extrinsic parameters (like camera position). High-quality hardware, stable environmental conditions, and regular maintenance all support accurate calibration. Advanced methods can reduce measurement errors and computation time, making the system more reliable.

Tip: Always match the camera, lens, and calibration process to the application. Regular validation and maintenance keep the machine vision system accurate and effective in manufacturing and automation.

Image resolution shapes the quality of every manufacturing inspection. To select the right resolution, engineers should define the smallest feature, calculate the needed pixels, and match the field of view. They must balance resolution with speed and cost for reliable product quality. Careful selection of sensor, lens, and lighting ensures the system captures clear images. As automation advances, new technologies like high-speed interfaces and 3D imaging will further improve quality and inspection accuracy.

FAQ

What happens if a camera has too high a resolution for the task?

A camera with too high a resolution creates large image files. This slows down processing and increases storage needs. The system may not work as fast as needed for real-time inspection.

How does lighting affect image resolution in machine vision?

Lighting helps the camera capture clear images. Good lighting reduces shadows and glare. This makes small features easier to see. Poor lighting can hide defects and lower the quality of the inspection.

Can a better lens improve image resolution?

Yes. A high-quality lens focuses light better on the sensor. This helps the camera use all its pixels. A poor lens can blur details, even with a high-resolution sensor.

How often should a machine vision system be calibrated?

Experts recommend calibrating the system regularly, such as once a month or after any hardware change. Regular calibration keeps measurements accurate and ensures the system works well.

See Also

Essential Guide To Camera Resolution In Machine Vision

How Image Recognition Enhances Quality Control In Machine Vision

Understanding Pixel-Based Machine Vision For Today’s Applications

A Deep Dive Into Dimensional Measurement Using Machine Vision

Exploring Image Processing Techniques In Machine Vision Systems