A resize machine vision system transforms industrial workflows by automating image resizing for faster inspection and reliable recognition. Manufacturers achieve up to a 75% reduction in inspection time and report over $1 million in production gains per site. The system continuously resizes each image, maintaining high image quality and supporting consistent recognition. AI-powered machine vision system solutions deliver precision defect detection, reducing error rates from 10% to below 1%. As a result, image recognition becomes more accurate, and inspection performance improves across sectors.

Sector Impact Manufacturing Inspection speed: one part every 2 seconds Retail 25% improvement in inventory turnover Energy 10:1 ROI, 20% cost reduction

Every resized image ensures optimal performance, allowing recognition tasks to run at peak efficiency. Any business that relies on image inspection can benefit from improved image processing, higher recognition accuracy, and better overall performance.

Key Takeaways

- Resize machine vision systems speed up image inspection and improve recognition accuracy, helping businesses save time and reduce errors.

- These systems prepare images by resizing and optimizing them for better defect detection, which boosts quality across industries like manufacturing, healthcare, and logistics.

- Using AI-powered resizing methods and maintaining image quality ensures reliable and consistent inspection results, even with different image sizes and shapes.

- Implementing these systems leads to significant cost savings by cutting labor, maintenance, and downtime expenses while increasing production efficiency.

- Successful adoption requires careful planning, integration, and ongoing training to maximize benefits and keep the system running smoothly.

What Is a Resize Machine Vision System?

Core Function

A resize machine vision system prepares images for advanced visual recognition tasks. This system acts as a crucial preprocessing step, ensuring that every image meets the requirements of modern vision models. By adjusting each image to a consistent size and format, the system enables reliable inspection and accurate recognition. The resize machine vision system does not simply change the dimensions of an image; it optimizes the image for recognition performance, often in ways that may not be visually obvious to humans.

Recent technical documentation highlights a learnable resizer module that adapts image resizing specifically for vision models. Unlike traditional resizing, this module learns how to resize images to maximize recognition performance. Models using this approach achieve higher recognition accuracy, even if the resized images do not look better to the human eye. For example, a learnable resizer improved recognition performance from 60.19% to 67.67% after the same training period. This demonstrates that the core function of a resize machine vision system is to enhance recognition, not just to make images look good.

A new architecture, Vision Transformer with Any Resolution (ViTAR), further advances this concept. ViTAR allows machine vision systems to process images of different sizes without fixed resizing. It uses fuzzy positional encoding to keep important spatial details, which improves recognition and inspection in fields like medical imaging and surveillance. This flexibility means that the system can handle a wide range of image shapes and resolutions, maintaining high recognition performance across diverse applications.

Note:

The resize machine vision system ensures that every image is ready for inspection and recognition, regardless of its original size or shape. This preparation leads to more accurate and reliable visual recognition in real-world scenarios.

Image Resizing Methods

Image resizing methods play a vital role in the performance of machine vision systems. Traditional methods include nearest neighbor, bilinear, and bicubic interpolation. These techniques adjust the size of an image by estimating new pixel values based on surrounding pixels. Bilinear interpolation, for example, is widely used in machine vision because it balances speed and image quality.

Recent research shows that the choice of resizing method and target resolution directly affects recognition performance. The table below summarizes how different image resolutions impact diagnostic performance in deep learning models for radiography:

| Image Resolution (pixels) | Diagnostic Performance (AUROC) Summary | Notes |

|---|---|---|

| 32 × 32 | Significantly lower performance; some diagnoses reach ~85-88% of optimal performance | Very low resolution limits diagnostic quality |

| 64 × 64 | Improved over 32 × 32; achieves over 85% of optimal AUROC for several labels (atelectasis, edema, effusion, thoracic mass) | Still suboptimal compared to higher resolutions |

| 128 × 128 | Intermediate performance; better than very low resolutions but less than optimal | |

| 224 × 224 | Near plateau of performance gains; commonly used resolution in prior studies | |

| 256 × 256 to 320 × 320 | Optimal performance plateau observed; AUROC improvements level off beyond this range | |

| 448 × 448 to 600 × 600 | No significant further gains; higher resolutions increase computational cost |

Bilinear interpolation was the resizing method in these studies, and models like ResNet34 and DenseNet121 were evaluated. The results show that resizing images to around 256 × 256 or 320 × 320 pixels provides the best balance between recognition performance and computational efficiency. Higher resolutions do not significantly improve recognition but do increase processing time and resource use.

AI-powered resizing methods, such as convolutional neural network (CNN)-based resizers, have emerged as powerful alternatives. These methods learn how to resize images in ways that boost recognition performance for specific inspection tasks. They adapt to the unique features of each image, leading to better recognition outcomes in complex scenarios.

Maintaining the aspect ratio during resizing is essential. Distorted images can confuse vision models and reduce recognition accuracy. Proper resizing ensures that the system preserves important features, leading to more reliable inspection and visual recognition.

- Scaling methods like Min-Max Scaling and Standardization normalize pixel intensity values. This normalization speeds up model training and improves recognition accuracy.

- Binning (quantization) reduces noise and standardizes intensity variations. Studies recommend using 32-64 grey levels and about 40 bins for optimal recognition performance.

- Feature transformation techniques, including scaling and normalization, enhance consistency across datasets. This consistency boosts model robustness and predictive performance.

- Resizing and scaling help manage pixel intensity variations and outliers. These steps directly affect the accuracy and reliability of machine vision models.

- Fixing unusual data and resizing features allow models to interpret images correctly, resulting in more accurate recognition and inspection outcomes.

The resize machine vision system uses these methods to prepare every image for inspection, ensuring that recognition tasks run smoothly and efficiently. By selecting the right resizing method and resolution, the system maximizes recognition performance while minimizing computational costs. This careful preparation supports high-quality inspection and visual recognition across industries.

Key Benefits

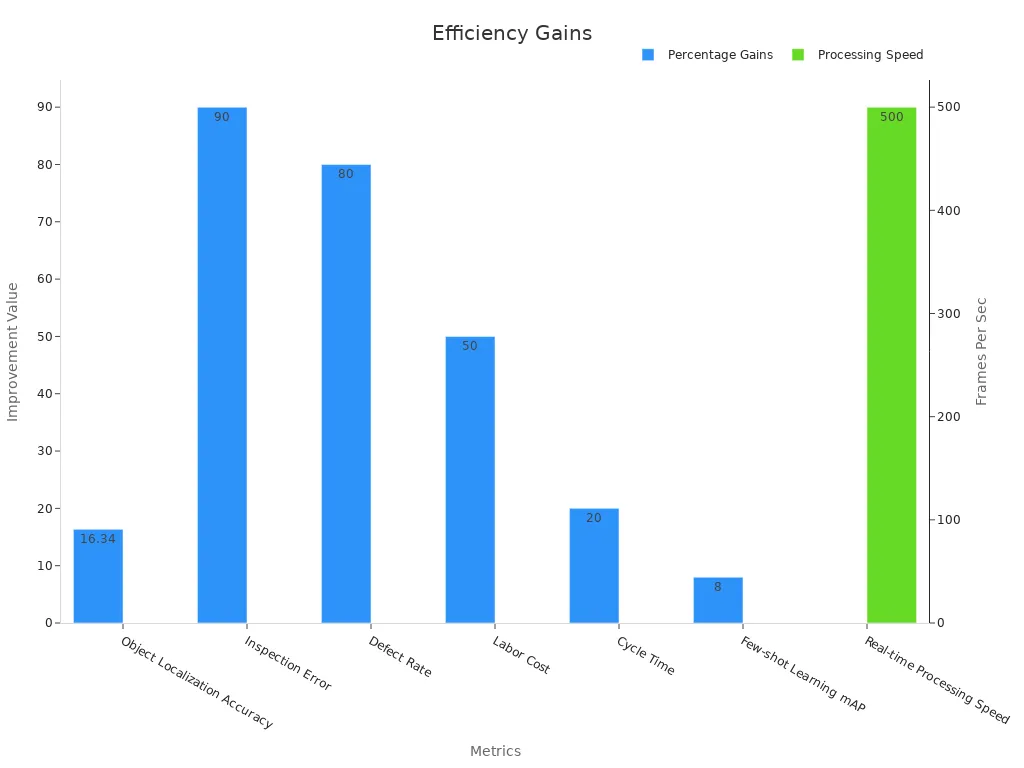

Efficiency Gains

A resize machine vision system delivers major efficiency gains in inspection automation. Companies like John Deere use advanced computer vision and machine learning to identify weeds in real time, which allows targeted herbicide application. This approach reduces waste and speeds up farming operations. IBM Maximo and VusionGroup also use edge-based vision systems for real-time inspection and asset monitoring. These systems enable immediate defect detection, reducing downtime and improving workflow efficiency. Inference engines process visual data instantly, cutting mean time to resolution by up to 65%. This rapid response minimizes costly downtime and keeps production lines moving.

| Metric | Improvement / Reduction | Description |

|---|---|---|

| Object Localization Accuracy | +16.34% | More precise bounding boxes and better detection |

| Inspection Error | >90% reduction | Compared to manual inspection |

| Defect Rate | Up to 80% reduction | Fewer defects detected |

| Labor Cost | ~50% reduction | Less spent on quality assurance labor |

| Cycle Time | Up to 20% faster | Shorter production cycles |

| Real-time Processing Speed | Up to 500 frames per second | High-speed mode enabling real-time analysis |

Flexibility

Modern inspection automation systems adapt to many operational needs. For example, industrial companies integrate computer vision algorithms with programmable logic controllers (PLCs) to create flexible automation solutions. These systems allow users to implement vision-based inspection through ladder programming, which improves efficiency and operational effectiveness. Wireless PLCs and advanced image processing boost gear sorting speed and accuracy. Automated cells controlled by PLCs increase production speed, reliability, and flexibility. This adaptability supports a wide range of inspection and recognition tasks across industries.

Cost Savings

Inspection automation with resize machine vision systems leads to significant cost savings. Maintenance costs drop by up to 40%, and downtime reduces by 15-50%. General Motors saved $20 million annually and cut downtime by 15% after implementing machine vision-based predictive maintenance. Companies also see equipment lifespan extensions of 20-40%. These savings come from fewer defects, less rework, and reduced labor costs. Inspection automation ensures that every image is processed for optimal recognition performance, which lowers quality control expenses.

- Maintenance cost savings: 15-40%

- Downtime reductions: 15-50%

- Equipment lifespan extension: 20-40%

- Savings compared to preventive maintenance: 8-12%

- Savings compared to reactive maintenance: up to 40%

- General Motors saved $20 million annually and reduced downtime by 15%

Improved Accuracy

Precision defect detection improves with advanced image resizing and inspection automation. Data augmentation methods, such as random cropping and padding, help machine vision models adapt to different environments. These techniques increase defect detection accuracy from 63% to 97%, a 34% improvement. Production yields rise, and false positive rates drop. In manufacturing, resizing and augmentation improve defect detection rates by an average of 32%. This leads to fewer defective products reaching customers and reduces rework. Inspection automation and defect analytics and reporting ensure high recognition performance and reliable visual recognition in every inspection.

Applications

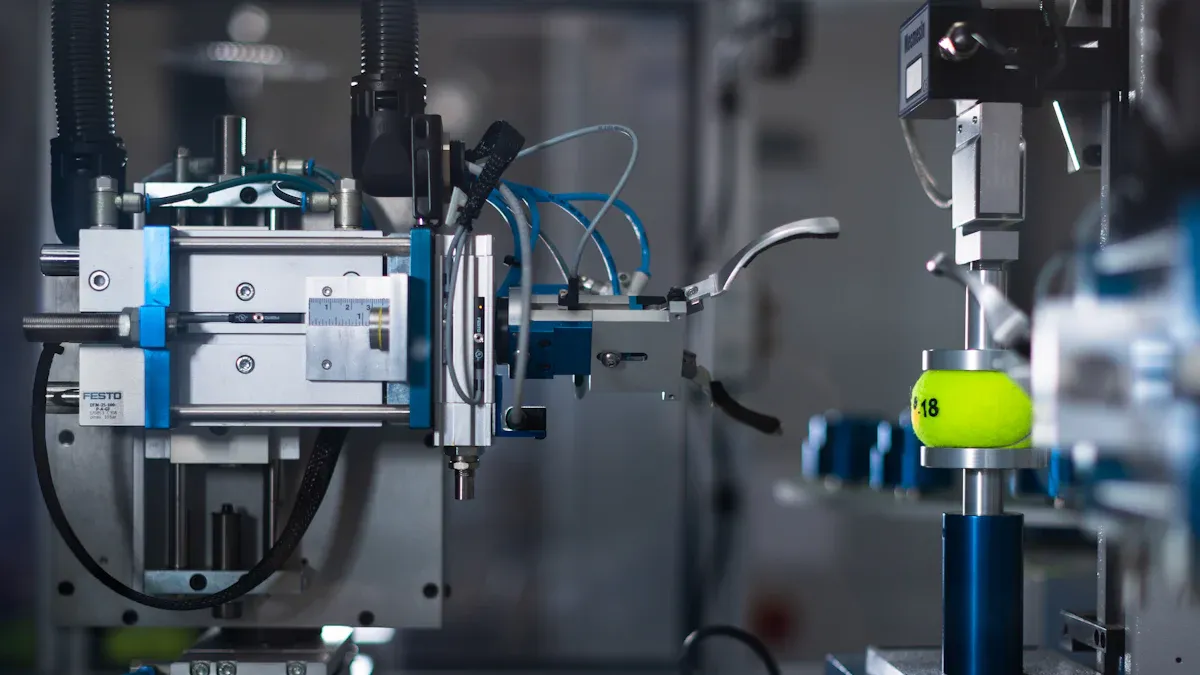

Manufacturing

Manufacturing companies rely on resize machine vision systems to improve inspection and recognition tasks. These systems use high-resolution cameras to capture detailed images of products on the assembly line. Automated optical inspection checks for defects in electronics, such as missing components or soldering issues. In the automotive sector, image recognition detects cracks, weld quality, and tire tread depth. Food and beverage factories use image-based inspection automation to check bottle caps for shape and print quality. Dimensional measurement ensures each part meets strict standards. By standardizing input image sizes, manufacturers achieve faster, more accurate recognition and reduce human error.

| Industry | Application Example | Benefit |

|---|---|---|

| Electronics | PCB inspection, solder joint analysis | Prevents faulty devices |

| Automotive | Crack and weld detection, brake pad inspection | Early defect detection, faster inspections |

| Food & Beverage | Bottle cap and packaging line inspection | Higher speed, reduced manual labor |

| Pharmaceuticals | Pill shape and packaging inspection | Ensures product quality |

Quality Control

Quality control teams use resize machine vision systems to maintain high product standards. These systems process every image to the same size, which helps recognition models find defects quickly. In textiles, image recognition spots stitching errors and fabric flaws. Pharmaceuticals use image-based inspection to check pill shape and coating. Dimensional measurement tools verify that each product matches design specifications. Letterbox resizing helps object detection models find defects even when products vary in size. Inspection automation reduces manual checks and increases accuracy.

Tip: Standardizing image sizes for machine learning models improves recognition and speeds up inspection.

Logistics

Logistics operations depend on fast, accurate image recognition for package handling. AI-powered OCR reads shipment labels from images, even when labels are damaged or at odd angles. These systems automate data extraction, reducing manual work and errors. Real-time image inspection tracks packages and creates digital delivery records. Packaging line inspection uses image recognition to verify label placement and package condition. Automated systems handle high volumes, scaling up as demand grows. Dimensional measurement tools check package size for sorting and shipping. By resizing images for consistent recognition, logistics companies improve speed, accuracy, and customer satisfaction.

- AI-powered OCR adapts to different fonts, languages, and label conditions.

- Real-time image tracking reduces disputes and increases transparency.

- Automated inspection lowers labor costs and speeds up processing.

Healthcare

Healthcare providers use resize machine vision systems to support diagnosis and treatment. High-resolution cameras capture medical images for analysis. Image recognition helps estimate blood loss, inspect medical devices, and monitor drug production. Standardizing image sizes ensures recognition models work accurately across different equipment. Inspection automation checks for defects in medical devices and packaging. In surgery, image-based systems assist doctors by highlighting important features. Dimensional measurement tools verify the size and shape of implants or instruments. These applications improve diagnostic accuracy and patient safety.

Note: AI-powered image recognition in healthcare leads to better outcomes and higher regulatory compliance.

Implementing AI-Powered Machine Vision System

Assess Needs

Organizations must first assess their needs before adopting an ai-powered machine vision system. They should review current operations and define what they want to achieve with image recognition and inspection. A structured approach helps teams identify gaps and set clear goals. The table below outlines key criteria to consider:

| Criteria Category | Key Considerations |

|---|---|

| Systematic Planning | Define project scope and team roles |

| Specification Development | Set image quality, productivity, and operational requirements |

| Operational Analysis | Review current inspection and recognition processes |

| Technical Data Quantification | Measure image quality, recognition accuracy, and downtime |

| Sensitivity and Tolerance | Set limits for image variations and defect detection |

| Sample and Documentation | Collect sample images and documentation for evaluation |

Teams should also evaluate data quality and accessibility. Clean, accurate, and relevant image data ensures the system delivers reliable recognition results. They must check if the data meets privacy and regulatory standards.

Integration Steps

Successful integration of live vision ai software requires careful planning. Teams should follow these steps:

- Choose the right AI technology for image recognition, such as deep learning models like CNNs.

- Build a cross-functional team with data scientists, engineers, and domain experts.

- Develop a pilot project using sample images to test recognition and inspection performance.

- Integrate live vision ai software with existing automation platforms, using open standards and middleware for smooth connectivity.

- Ensure hardware compatibility by selecting robust cameras and sensors that maintain image quality in real-world conditions.

- Calibrate the system to preserve image quality during resizing and recognition.

- Validate performance with factory and site acceptance testing, checking image quality, recognition accuracy, and system reliability.

Modular system designs and turnkey solutions simplify integration. Teams should match vendor strengths with their own needs, considering scalability and future upgrades.

Training and Support

Training and support play a vital role in long-term success. Employees need hands-on training to use the ai-powered machine vision system and interpret image recognition results. Ongoing support ensures the system maintains high image quality and adapts to new inspection challenges. Teams should monitor performance using dashboards and key metrics. Regular audits and calibration help maintain image quality and recognition accuracy. Organizations should also address ethical and legal considerations, ensuring compliance with privacy laws and industry standards.

Tip: Continuous training and support help teams get the most value from their machine vision investment.

Challenges and Solutions

Technical Barriers

Resize machine vision systems face several technical barriers that can affect image inspection and overall performance. One common challenge involves maintaining the correct aspect ratio during image resizing. If the aspect ratio changes, the system may misinterpret features, leading to errors in inspection. Another technical issue arises when models struggle to distinguish objects with similar colors in an image. This can cause misclassification, as the system cannot isolate important features for inspection. JPEG compression adds another layer of difficulty. When an image is compressed twice, subtle clues needed for inspection may disappear, making it hard for the system to detect resizing or changes. Traditional calibration methods also present challenges. They require many runs to adjust parameters, which increases computational costs and slows down performance. Calibration must be repeated for different image types and inspection tasks, making the process tedious and time-consuming.

Tip: Learnable resizers and differentiable parameter learning can help overcome these barriers. These tools adapt to each image and inspection scenario, improving performance and reducing the need for repeated calibration.

Cost Concerns

Financial considerations play a major role in adopting machine vision systems for image inspection. Customization costs can range from $50,000 to $200,000, and installation may take up to six weeks. Many manufacturing firms expect a return on investment within 18 months. However, companies often see a 40% reduction in manual inspection costs and significant energy savings. For example, one pharmaceutical company projected $420,000 in annual savings by using energy-efficient systems. Some systems cost 22% more if they use less than 50 watts, but the long-term savings can outweigh the initial expense.

| Financial Aspect | Details / Quantification |

|---|---|

| Customization Costs | $50,000 to $200,000 |

| Installation Time | Up to 6 weeks |

| ROI Requirement | 68% of firms require ROI within 18 months |

| Cost Reduction Example | 40% reduction in manual inspection costs |

| Energy Efficiency Savings | $420,000 annual savings projected |

| Energy-Efficient System Premium | 22% price premium for low-power systems |

System Compatibility

System compatibility remains a key concern for image inspection and performance. Many organizations use legacy equipment that may not work well with new machine vision systems. Compatibility issues can disrupt image inspection and reduce performance. To address this, teams should conduct technology audits to identify problem areas. Middleware solutions can bridge gaps between old and new systems, allowing smooth image data exchange. Standardizing data formats and protocols also helps reduce compatibility problems. Frame grabbers that support industry standards like Camera Link and GigE Vision ensure reliable image transfer and inspection. These devices synchronize and check images, improving system performance and future-proofing the setup.

- Conduct audits to find compatibility issues in image inspection systems.

- Use middleware and integration tools to connect different systems.

- Standardize data formats and use frame grabbers for reliable image handling.

Resize machine vision systems help teams process every image with speed and accuracy. These solutions use AI to detect defects in each image, which improves quality across industries. Flexible deployment allows companies to adapt image inspection to many tasks. Teams see better results when they upgrade their image processing tools. Every image that passes through these systems supports higher productivity and fewer errors.

FAQ

What is a resize machine vision system?

A resize machine vision system prepares every image for inspection. It adjusts image size and format, which helps recognition models work better. This system supports automated optical inspection and improves recognition performance in many industries.

How does image resizing affect recognition performance?

Image resizing changes the input size for recognition models. Proper resizing keeps image quality high and maintains important features. This process boosts recognition accuracy and supports precision defect detection during inspection automation.

Why is real-time inspection important in manufacturing?

Real-time inspection uses high-resolution cameras and live vision ai software to check products instantly. This approach finds defects quickly, reduces waste, and improves overall performance. Manufacturers rely on real-time inspection for fast, accurate visual recognition.

Can resize machine vision systems help with packaging line inspection?

Yes. These systems standardize image sizes for packaging line inspection. They support dimensional measurement and defect analytics and reporting. This ensures every package meets quality standards and improves inspection results.

What are the benefits of using ai-powered machine vision systems?

Ai-powered machine vision systems deliver faster inspection, better image quality, and higher recognition performance. They automate defect detection, reduce manual labor, and support flexible inspection tasks across industries.

See Also

Essential Advantages And Features Of Machine Vision In Medical Devices

Ensuring Precise Alignment With Machine Vision Systems In 2025

A Clear Guide To Image Processing In Machine Vision Systems

Comprehensive Overview Of Inspection Using Machine Vision In 2025

Fundamentals Of Camera Resolution For Machine Vision Systems