Testing data machine vision system plays a vital role in achieving accurate and reliable machine vision systems. A recent electronics manufacturer’s study showed a 97.2% defect detection rate after improving testing data, compared to 93.5% with older methods. Proper validation and real-time monitoring help maintain high performance and reduce errors in quality control. These steps protect quality control in machine vision systems and prevent costly mistakes during production. Without careful testing data machine vision system, quality control failures can lead to missed defects and lower product quality.

Key Takeaways

- Testing data is essential to build reliable machine vision systems that catch defects and improve product quality.

- Using diverse and well-labeled datasets helps machine vision models work well in real-world conditions and reduces errors.

- A strong validation process checks model accuracy and consistency early and throughout the system’s lifecycle to maintain high performance.

- Data validation frameworks ensure data quality by catching errors in real time, which keeps machine vision systems accurate and trustworthy.

- Real-time monitoring detects problems quickly during production, helping teams fix issues fast and keep quality control running smoothly.

Testing Data Machine Vision System

Importance of Testing

Testing data machine vision system forms the backbone of reliable machine vision systems. A structured approach to testing ensures that each machine vision system can handle the wide range of challenges found in real-world environments. Dataset diversity stands out as a key factor. When datasets lack variety, models struggle to generalize, leading to errors during production or quality control. Many datasets remain small or lack rare cases, which reduces the robustness of deep learning models. Annotation quality also varies, sometimes requiring extra cleanup before use. Synthetic datasets help by adding variety, but they may not always capture the full complexity of real-world images.

Note: Most datasets score low on fairness and regulatory compliance. For example, 91% of datasets score 2 or less out of 5 for fairness, and 89% have low compliance scores. This highlights the need for better dataset design in machine vision systems.

Testing data machine vision system also involves using performance metrics to measure how well a machine vision system works. Metrics like accuracy, precision, recall, and enrichment factors help teams understand strengths and weaknesses. Studies show that using structured performance metrics can improve early detection rates by up to 15 times compared to older methods. Machine vision systems using these metrics can achieve hit rates as high as 88.6%, far above traditional limits.

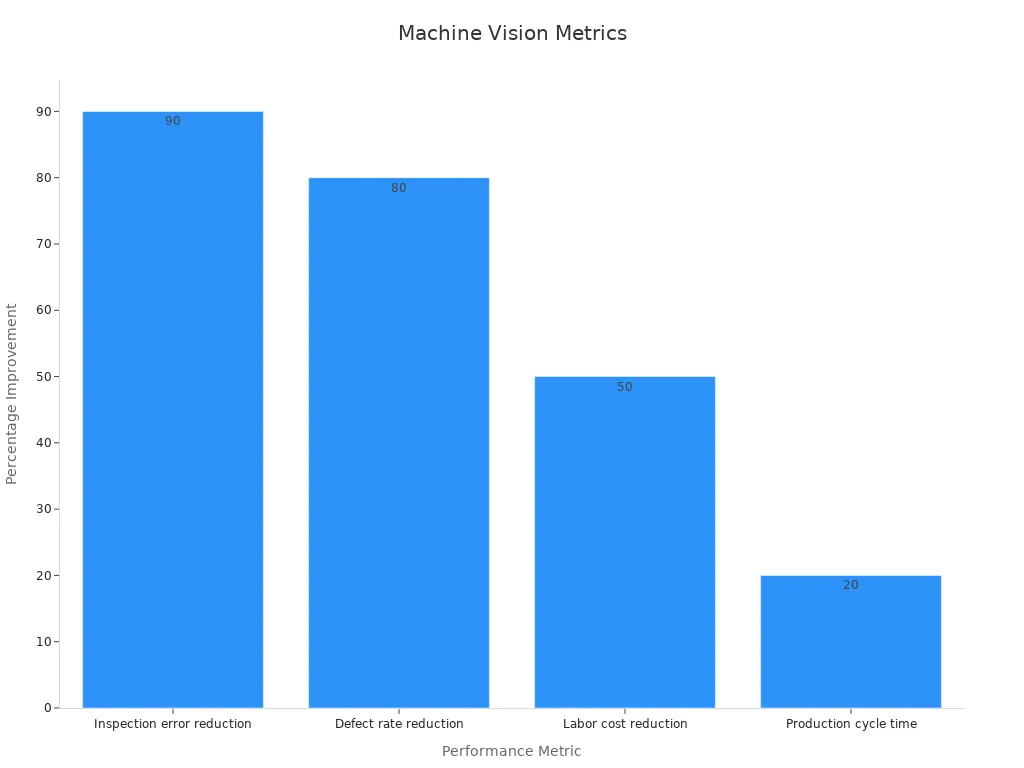

Comprehensive testing leads to better results in quality control and manufacturing. For example, advanced machine vision systems reduce inspection errors by over 90% and lower defect rates by up to 80%. These systems also speed up production, processing up to 10,000 parts per hour. In agriculture, machine vision systems achieve sorting accuracy rates of 94-98% for strawberries and over 94% for papaya size classification. These results show that thorough testing improves both quality and productivity.

Common Testing Methods

Teams use several methods to test machine vision systems. Each method checks different aspects of the system to ensure strong performance in production and quality control.

- Defect Detection: Machine vision systems scan images for defects such as cracks, deformations, or contamination. On MVTec’s capsule images, defect detection achieved high rates even without defective samples in training. This shows the power of deep learning models and image processing algorithms in real-world scenarios.

- Optical Character Recognition (OCR): OCR systems read printed codes on packaging, such as batch numbers and expiry dates. In pharmaceutical manufacturing, OCR reads alphanumeric codes in under 50 milliseconds, keeping up with fast production lines.

- Robotic Guidance: Machine vision systems guide robots during assembly or inspection. These systems use image processing algorithms to locate objects and direct robotic arms with high precision, improving both speed and quality.

| Performance Metric | Numerical Evidence |

|---|---|

| Inspection error reduction | Over 90% decrease compared to manual inspection |

| Defect rate reduction | Up to 80% fewer defects |

| Labor cost reduction | About 50% reduction in quality assurance labor costs |

| Production cycle time | Up to 20% faster production cycles |

Testing data machine vision system also includes real-world simulation. Teams use images from different lighting conditions, camera types, and environments to test how well the machine vision system adapts. This step helps catch problems that might only appear during actual production or processing.

Tip: Data collection and labeling play a big role in building strong machine vision systems. High-quality images and accurate labels make validation and framework testing more effective.

Validation and Data Validation Framework

Validation Steps

Validation forms the backbone of every reliable machine vision system. Teams use validation to check accuracy, consistency, and reliability at every stage of the machine learning lifecycle management process. A strong validation process helps ensure that the machine vision system performs well in real-world conditions and maintains high quality over time.

A typical validation process includes several important steps:

- Teams collect ground truth data as a trusted reference for training, validation, and testing. This step improves baseline predictions and validation outcomes for deep learning models.

- They compare model predictions to ground truth using performance metrics like accuracy, precision, recall, and F1-score. These metrics provide an objective way to measure how well the machine vision system works.

- User-level data splits and separate validation datasets help improve model generalization and reliability. This approach reduces overfitting and ensures the system can handle new data.

- Calibration steps align model confidence scores with real-world outcomes. For example, Philips Consumer Lifestyle BV reduced labeling effort by 3-4% without losing quality by using calibration with ground truth data.

- Continuous monitoring for data drift and retraining with fresh ground truth data keeps the machine vision system accurate as conditions change.

- Human-machine collaboration in labeling, supported by AI-assisted annotation tools, reduces errors and improves ground truth quality. This step increases the reliability of deep learning models.

- Advanced driver-assistance systems and driver monitoring systems rely on ground truth validation to ensure safety-critical detection and tracking functions work reliably in all conditions.

Tip: Start validation early and continue throughout the machine learning lifecycle management process. Early validation helps catch issues before they affect production or quality control.

Documented cases show that following these validation steps leads to measurable improvements in accuracy and consistency. For example, UnitX Labs improved imaging accuracy and consistency by using advanced lenses, optics, and rigorous calibration techniques. Retinal imaging with infrared lenses achieved high-quality scores, and convolutional neural networks predicted image quality with a low mean absolute error. In manufacturing, vision-guided robotics systems using deep learning models improved tracking accuracy and system responsiveness, resulting in a 27% increase in production throughput and a 34% reduction in waste caused by false positives.

A comprehensive validation plan often includes:

- Defining components, interfaces, and acceptance criteria.

- Starting testing early and conducting continuous testing.

- Using manual, automated, functional, and performance testing.

- Documenting and tracking issues for timely resolution.

- Making continuous improvements by evaluating testing effectiveness and adopting new tools.

- Maintaining the testing environment for consistent and reproducible results.

These best practices help ensure that the machine vision system delivers high quality and reliability in production and advanced inspection tasks.

Framework Benefits

A data validation framework brings structure and consistency to the machine learning lifecycle management process. This framework enforces real-time data integrity checks and validation rules, which improve input data quality and reduce errors such as missing values or incorrect labels. High-quality data and strong data integrity checks are essential for building robust machine vision systems.

The benefits of using a data validation framework include:

- Real-time data validation processes maintain system robustness in dynamic environments. The framework detects and handles anomalies or edge cases quickly, ensuring consistent model performance.

- In autonomous vehicles, the framework filters out poor-quality images caused by bad lighting or weather. This step reduces accident risks and enhances system adaptability and reliability.

- In medical imaging, the framework ensures image resolution and consistency. It flags artifacts that could cause diagnostic errors, improving patient outcomes and system trustworthiness.

- Data validation frameworks support strong machine learning pipelines by enforcing data integrity checks at every stage. This approach helps maintain high-quality data and reliable deep learning models.

- Real-time data validation and integrity checks help maintain system quality during production and automated quality control. The framework ensures that only valid data enters the machine vision system, reducing the risk of errors.

- Quantitative model validation techniques, such as Bayesian hypothesis testing and reliability-based methods, assess model accuracy and uncertainty. These methods help avoid errors and confirm model robustness under real-world conditions.

- In manufacturing, data validation frameworks help maintain quality by catching data issues before they affect production. This step supports advanced inspection and real-time inspections, leading to fewer defects and higher product quality.

- Machine learning lifecycle management benefits from a framework that tracks data integrity, monitors performance, and supports continuous improvement. The framework helps teams respond quickly to changes in data or production environments.

Note: A well-designed data validation framework is not just a tool. It is a foundation for building reliable, high-quality machine vision systems that can adapt to changing conditions and deliver consistent results.

A data validation framework supports every stage of machine learning lifecycle management, from data collection and labeling to model deployment and real-time monitoring. By enforcing data integrity checks and supporting high-quality data, the framework ensures that deep learning models and image processing algorithms deliver accurate, reliable results in production and advanced inspection settings.

Real-Time Monitoring

Monitoring Tools

Real-time monitoring plays a key role in keeping a machine vision system accurate and reliable. Many industries use real-time monitoring to watch how machine vision systems perform during processing and production. This approach helps teams spot problems early, such as sudden drops in accuracy or changes in image quality. When a machine vision system processes thousands of images every hour, even a small error can lead to big issues in quality control or automated quality control.

Teams use several monitoring tools to track system health. These tools check for data drift, track performance metrics, and send real-time alerts if something goes wrong. For example, real-time monitoring tools can measure inference time, throughput, and error rates as the system processes each image. If the system detects a spike in false positives or a slowdown in processing, it sends an alert so engineers can fix the problem before it affects production. Companies like Ford and General Motors have reported fewer errors and less downtime after adding real-time monitoring to their machine vision systems. Predictive maintenance powered by real-time monitoring can extend the lifespan of a vision system by 20% to 40%.

| Metric | Description | Impact on Machine Vision Systems |

|---|---|---|

| Inference Time (Latency) | Time taken to process an image, critical for real-time applications | Reduced latency improves responsiveness and user experience |

| Throughput (Frames Per Second) | Number of images processed per second | Higher throughput enables efficient handling of large data volumes |

| Error Rates | Frequency of false positives and false negatives | Reduction enhances system reliability and trustworthiness |

| Downtime | Time system is non-operational due to performance issues | Early detection reduces downtime, ensuring higher availability |

| Scalability and Cost-Effectiveness | Ability to scale and optimize resources without manual intervention | Supports business growth and reduces operational expenses |

Performance Metrics

Performance metrics help teams measure how well machine vision systems work during real-time inspections and processing. Metrics like accuracy, precision, recall, and F1-score show if the system can process images correctly and keep up with production speed. Continuous real-time monitoring of these metrics helps teams catch problems early and retrain deep learning models when needed.

Empirical studies show that using performance metrics improves system reliability. For example, facial expression recognition systems use accuracy and correlation with human ratings to prove they work well in real-world scenarios. Monitoring tools also track data drift and help teams recalibrate models to maintain high reliability. In healthcare and automotive industries, real-time monitoring and real-time data validation keep machine vision systems performing at their best, even as conditions change.

Real-time data validation checks every image as it enters the system. This step ensures only high-quality images reach the image processing algorithms. Real-time data validation also helps maintain data integrity and supports strong machine learning pipelines. By combining real-time monitoring, real-time data validation, and advanced image processing algorithms, teams can keep machine vision systems running smoothly during all stages of processing and production.

Object Detection in Practice

Testing for Object Detection

Object detection stands at the core of every modern machine vision system. Teams use object detection to find and classify items in images, which helps with quality control and advanced inspection. Testing for object detection starts with data collection and labeling. Engineers gather thousands of images from real production lines. They label each image to show where objects or defects appear. This step ensures high-quality data for training deep learning models.

During testing, teams use performance metrics like recall, F1 score, and accuracy. These metrics show how well object detection finds defects or missing parts. For example, systematic testing improved the mean intersection over union from 0.68 to 0.83, which means better alignment between predicted and real object locations. Annotation time dropped by over 50%, so teams spent less time labeling images while keeping quality high.

| Metric | Numerical Evidence | Interpretation/Impact |

|---|---|---|

| F1 Score | Improved after several testing cycles | Higher accuracy and less manual effort |

| Mean Intersection over Union (IoU) | Increased from 0.68 to 0.83 | Better bounding box alignment |

| Annotation Time Reduction | Up to 53.82% reduction | Faster data labeling without losing quality |

Object detection testing also uses real-time inspections. Machines process images up to 80 times faster than humans. This speed helps with quality control during production. Machines achieve recall rates of 100% and accuracy of 98.5%, which means fewer missed defects and higher product quality.

Teams should always test object detection models with images from different lighting, angles, and backgrounds. This practice ensures the machine vision system works well in all production settings.

Industry Applications

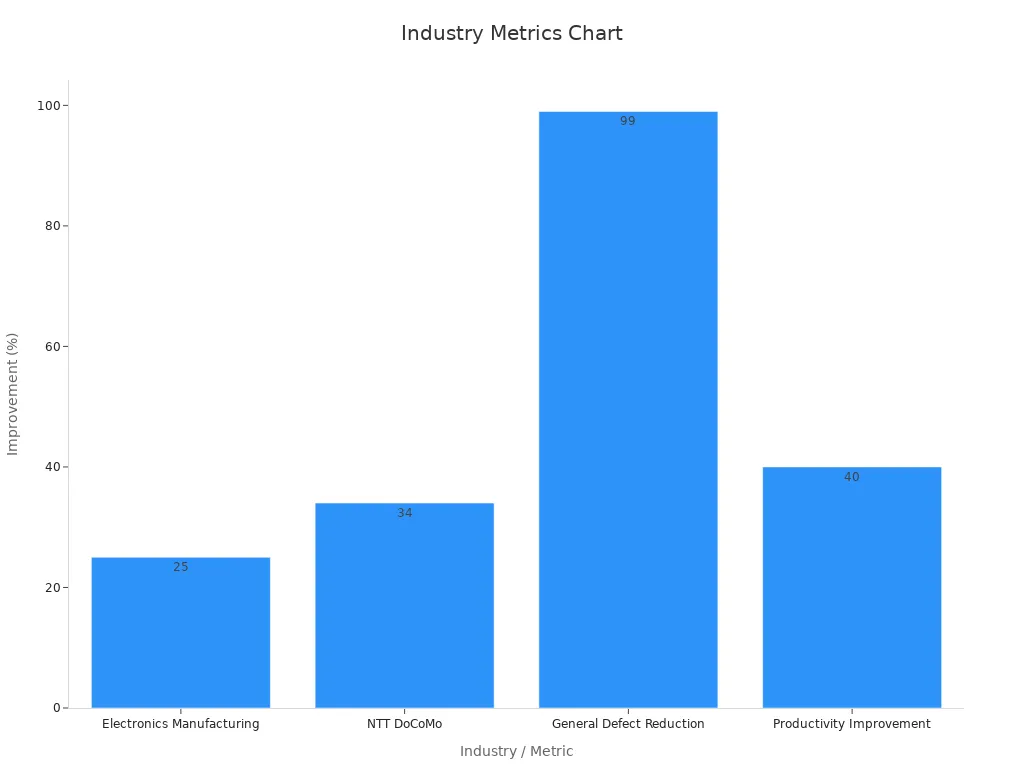

Manufacturing relies on object detection for quality control and inspection. In electronics manufacturing, object detection increased defect detection accuracy by 25%. NTT DoCoMo improved defect detection by 34% using AI. Some factories saw a 99% reduction in defective products, which saved money and improved quality. Machines now inspect products 80 times faster than humans, boosting productivity by 40%.

| Industry / Metric | Statistic / Result | Impact / Interpretation |

|---|---|---|

| Electronics Manufacturing | 25% increase in defect detection accuracy | Improved quality and reduced faulty products |

| NTT DoCoMo (Telecommunications) | 34% improvement in defect detection via AI | Enhanced defect detection through AI integration |

| General Defect Reduction | 99% reduction in defective products | Significant waste reduction and quality assurance |

| Object Detection Performance | Recall: 100%, F1 Score: 92.02%, Accuracy: 98.5% | High reliability and precision in defect identification |

| Machine vs Human Inspection | Machine recall: 0.842, precision: 0.837 | Machines outperform humans (recall 0.804, precision 0.79) |

| Speed of Inspection | Machines complete tasks 80+ times faster than humans | Greatly increased inspection throughput |

| Productivity Improvement | 40% boost compared to manual methods | Enhanced operational efficiency |

| Industry Applications | Automotive, Electronics, Pharmaceuticals, Food, Semiconductor | Broad applicability of machine vision systems |

In the automotive sector, object detection helps with inspection and quality control. Autonomous vehicles use object detection to spot other cars, pedestrians, and obstacles. This technology keeps passengers safe and supports real-time inspections during production.

Healthcare uses object detection in medical imaging. Hospitals track equipment and supplies, while doctors use object detection to find tumors in X-rays and MRI scans. Deep learning models help classify medical images, which improves diagnosis and patient safety. In aerospace, engineers use object detection to find defects in composite materials, making inspections faster and more accurate.

Object detection testing in these industries leads to better quality, faster production, and safer products. Machine vision systems now support advanced inspection and quality control across many sectors.

Testing data machine vision system ensures accuracy and reliability in every machine vision system. Teams achieve high-quality data through careful data collection and labeling, strong data integrity checks, and a robust data validation framework. Real-time monitoring and real-time data validation help maintain quality during production and advanced inspection. Object detection, deep learning models, and image processing algorithms support automated quality control in manufacturing and processing. Continuous validation and machine learning lifecycle management improve quality control and keep systems ready for real-time inspections. Teams should stay updated on new frameworks and best practices.

FAQ

What is the role of testing data in a machine vision system?

Testing data helps a machine vision system find errors before production. Teams use it to check quality control, improve object detection, and make sure deep learning models work well during inspection and processing.

How does a data validation framework improve data quality?

A data validation framework checks data integrity and quality at every step. It uses real-time data validation and data integrity checks to catch errors early. This process supports strong machine learning pipelines and keeps high-quality data for advanced inspection.

Why is real-time monitoring important in manufacturing?

Real-time monitoring tracks machine vision systems during production. It finds problems fast, like drops in image quality or system errors. This helps teams fix issues quickly and keeps automated quality control running smoothly.

What steps help ensure high-quality data for object detection?

Teams use careful data collection and labeling. They test images from different settings. They use validation and real-time inspections. These steps help deep learning models find objects and defects with high accuracy in manufacturing and processing.

How do machine vision systems support quality control in production?

Machine vision systems use image processing algorithms and real-time inspections. They check products for defects during production. This improves quality, reduces waste, and supports advanced inspection in many industries.

See Also

Essential Insights Into Computer Vision And Machine Vision

A Deep Dive Into Synthetic Data For Machine Vision

Understanding Fundamental Concepts Of Sorting Vision Systems