A time series machine vision system observes changes in scenes by analyzing sequences of images over time. This approach gives users a deeper understanding of patterns and visual changes. In eye-tracking studies, dynamic images, which shift across multiple frames, improved visual search efficiency and cognitive performance. The best results appeared when images changed for about 9000 milliseconds. Industries like security and manufacturing need this dynamic insight, as a machine vision system that detects changes over time helps solve real-world challenges. Unlike static analysis, time series machine vision systems capture important trends that single images might miss.

Key Takeaways

- Time series machine vision systems analyze sequences of images over time, helping detect changes and patterns that single images miss.

- These systems improve accuracy and speed in industries like manufacturing, healthcare, and security by spotting problems early and providing real-time alerts.

- Combining 2D and 3D vision with time series data gives a clearer, deeper understanding of objects and movements in space and time.

- Real-time monitoring and predictive analysis help reduce downtime, improve safety, and support faster decision-making.

- Challenges include handling large data amounts, needing powerful computers, and developing specialized algorithms to process complex time and spatial information.

Core Uniqueness

Temporal Data

A time series machine vision system stands out because it uses temporal data. This means it looks at a series of images or video frames, not just one picture. By tracking how things change from one frame to the next, the system can spot patterns and trends that a single image would miss. For example, in a factory, a 2d machine vision system might check if a part looks correct in one photo. A time series machine vision system, however, can watch the part move along the line and notice if something changes over time, like a slow shift in color or shape.

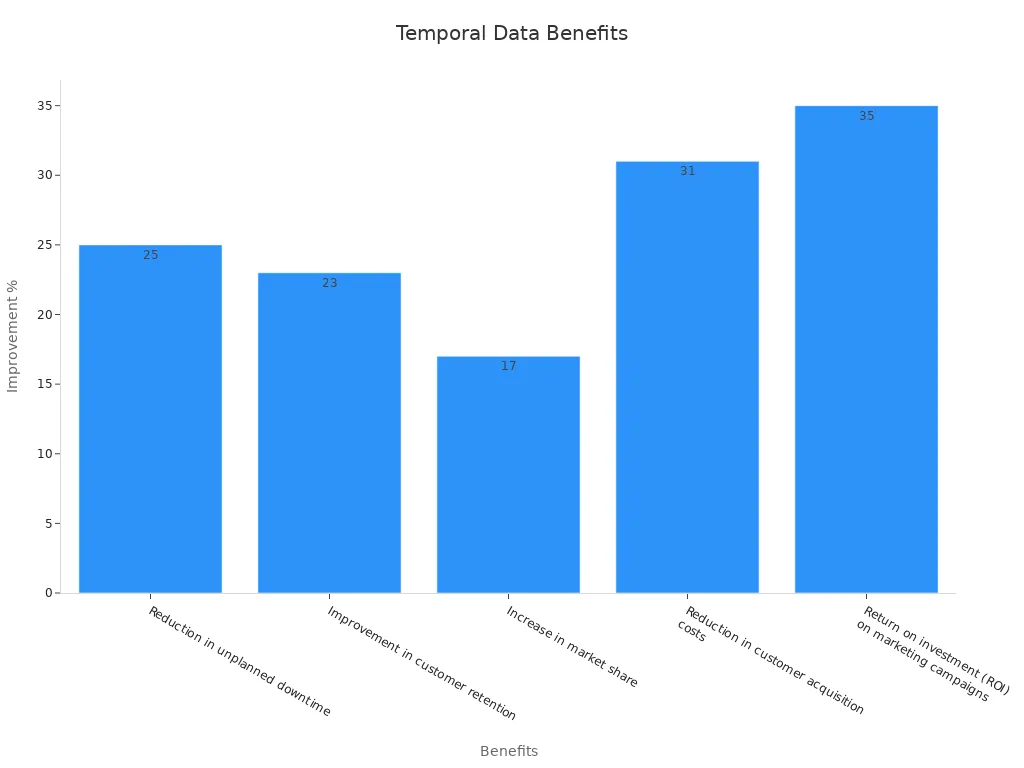

Integrating both historical and real-time data allows these systems to predict when a machine might fail. This predictive maintenance helps reduce unplanned downtime by up to 25%. It also makes defect detection faster and more accurate, dropping error rates from about 10% with manual checks to below 1% with AI-driven systems. These improvements help factories run more smoothly and save money.

| Benefit | Documented Improvement |

|---|---|

| Reduction in unplanned downtime | 25% |

| Improvement in customer retention | 23% |

| Increase in market share | 17% |

| Reduction in customer acquisition costs | 31% |

| ROI on marketing campaigns | 35% |

A 2d machine vision system can inspect one part every two seconds. When using a time series machine vision system, error rates drop below 1%, while manual inspections have about a 10% error rate. This shows how adding temporal data boosts both speed and accuracy.

Beyond Static Images

Traditional 2d machine vision focuses on single images. It checks for defects or measures objects in one frame. This method works well for simple tasks, but it misses changes that happen over time. A time series machine vision system, on the other hand, can analyze sequences of images. It can see if a product slowly changes color, if a machine vibrates more than usual, or if a person moves in a certain way.

3d machine vision adds another layer. It captures depth and shape, making it possible to see objects in three dimensions. When combined with time series analysis, 3d machine vision can track how objects move and change in space over time. For example, in quality control, a 3d machine vision system can spot tiny shifts in a product’s shape that might signal a problem. In security, it can follow a person’s movement through a room, not just in two dimensions but in three.

A 2d machine vision system might miss these subtle changes. By using both 2d and 3d machine vision, and by looking at how things change over time, a time series machine vision system gives a much clearer picture. This approach helps industries catch problems early, improve safety, and make better decisions.

Some studies show that traditional statistical methods still perform better than machine learning models for certain forecasting tasks. For example, in a large test with over 1,000 time series, classic methods were more accurate and used fewer computer resources than deep learning models that treat time series as images. However, new systems like ForCNN, which use deep learning and image-based analysis, are catching up. These systems can now match traditional methods in many cases, especially when using 3d machine vision and time series data together.

Note: The combination of 2d and 3d machine vision with time series analysis is still growing. As technology improves, these systems will likely become even more powerful and efficient.

Key Features

Pattern Recognition

Time series machine vision systems excel at finding patterns in sequences of images. They do not just look at one frame. They study how things change over time. For example, 2d machine vision can spot a scratch on a product in one image. When it uses time series data, it can also see if the scratch gets bigger or smaller in later frames. Deep learning models like CNNs and Vision Transformers help these systems learn what normal patterns look like. They can even turn numeric time series into images for better analysis. Many factories use image processing software to help with this task.

Note: Pattern recognition helps companies catch problems early and improve product quality.

Event Detection

Event detection means spotting important changes as they happen. Time series machine vision systems can notice when something unusual occurs in a video. For example, they can detect if a machine stops working or if a person enters a restricted area. 2d machine vision systems can track these events frame by frame. Real-time alerts help workers respond quickly. LSTM models and other deep learning tools make this possible. These systems also support object tracking, which means they can follow moving items or people across many frames.

Predictive Analysis

Predictive analysis uses past data to guess what might happen next. Time series machine vision systems can look at trends and forecast future events. For example, they can predict when a machine might break down. 2d machine vision systems use this feature to plan maintenance before problems occur. Real-time predictions help reduce downtime and save money. Vision Transformers and other advanced models make these forecasts more accurate.

Benefits of Time Series Machine Vision System

Accuracy and Context

Time series machine vision systems improve accuracy by using sequences of images instead of single snapshots. These systems see how objects or scenes change over time. This approach gives more context to each event. For example, in industrial automation, the system can track the timing of a machine’s movement and spot small changes that signal a problem. By using real-time data, the system can adjust quickly and keep processes running smoothly. Synchronization between cameras and sensors helps the system capture every detail. This leads to better decisions and fewer mistakes.

Anomaly Detection

Detecting unusual events is a key benefit of time series machine vision. The system compares current images to past ones and finds patterns that do not fit. In manufacturing, this means catching machine failures before they cause downtime. In healthcare, real-time monitoring of patient vitals helps doctors act fast. The AD-GS framework shows that machine vision systems can reach 96.8% accuracy in anomaly detection, with a false positive rate of only 1.8%. Reaction time efficiency stands at 98.4%, and latency stays below 15 milliseconds. These numbers show how real-time anomaly detection supports automation and safety.

| Industry / Metric | Description / Outcome | Numerical Data / Performance Metrics |

|---|---|---|

| Finance | Real-time anomaly detection used to reduce fraud | 30% reduction in fraudulent transactions |

| Healthcare | Patient vitals monitored with anomaly detection for timely intervention | Improved patient outcomes and reduced hospital stays |

| Manufacturing | Machinery monitored for early failure detection | Reduced downtime and increased productivity |

| AD-GS Framework (Machine Vision) | Anomaly detection system performance metrics | Accuracy: 96.8%, False Positive Rate: 1.8%, Reaction Time Efficiency: 98.4%, Latency: <15 ms, Computational Overhead: 10.2% less |

| Market Projection | Growth of anomaly detection market | Projected $18 billion by 2029, CAGR 17.4% |

Real-Time Monitoring

Real-time monitoring gives users instant feedback. In industrial automation, the system checks machines and products as they move. This helps workers fix problems right away. Real-time data transmission and low-latency data transfer keep information flowing without delay. Hospitals use real-time monitoring to watch patients and respond to changes quickly. Security teams rely on real-time communication and synchronization to track people or objects across many cameras. Timing is critical in these settings. Real-time systems help prevent accidents and improve results in many fields.

Real-time monitoring and forecasting help companies stay ahead of problems. This leads to safer workplaces, better health care, and stronger security.

Challenges

Data Complexity

Time series machine vision systems must handle huge amounts of data. Each image capturing sensor collects many frames every second. When 3d machine vision is involved, the data grows even more. These systems need to track objects in three dimensions and over time. This creates a challenge for time synchronization and storage. Synchronization between sensors becomes critical, especially when multiple cameras work together. Timing errors can cause the system to miss important changes. Studies show that simpler models like XGBoost often perform better than deep learning models on highly stationary data. Deep learning models sometimes miss sharp peaks in the data, which leads to less accurate results. The complexity of the data, including stationarity and temporal dependencies, affects how well the models work.

Computational Needs

Processing time series data from 3d machine vision systems requires strong computers. The system must analyze many frames quickly to keep up with real-time demands. Time-sensitive networking helps move data between devices without delay. Time synchronization ensures that all parts of the system work together. The WOODS benchmark suite shows that current deep learning models struggle with video tasks that require out-of-distribution generalization. These models need a lot of memory and power. As more industries use 3d machine vision, the need for faster and more efficient computers grows. Timing and synchronization challenges become even more important as systems scale up.

Specialized Algorithms

Advanced time series machine vision systems rely on specialized algorithms. These algorithms must handle complex tasks like anomaly detection, failure classification, and Remaining Useful Life estimation. 3d machine vision adds another layer of difficulty, as algorithms must process both spatial and temporal information. Time-sensitive networking and time synchronization play a key role in making sure data from different sensors lines up correctly. Researchers have found that preprocessing, modeling temporal relationships, and integrating deep learning methods all present challenges. The integration of 3d machine vision with optimization systems remains an emerging area. Developers continue to search for algorithms that can handle these demands while keeping systems reliable and fast.

Note: As time series machine vision systems advance, the challenges of data complexity, computational needs, and specialized algorithms will shape the future of this technology.

Applications

Industrial Automation

Time series machine vision systems have transformed industrial automation. These systems monitor assembly lines and detect changes in products as they move. They support real-time quality inspection by analyzing sequences of images, not just single snapshots. This approach helps factories catch defects early and reduce waste. For example, a system can spot a slow color change in a product that signals a problem. Real-time data transmission allows workers to respond quickly to issues. Action recognition helps machines understand if a robot arm moves correctly or if a part is missing. Real-time monitoring and automation together improve safety and boost productivity in industrial automation.

Healthcare Imaging

Healthcare imaging has seen major improvements with time series machine vision systems. Deep learning models, such as recurrent neural networks, capture changes in medical images over time. These systems improve detection, segmentation, and classification tasks. Doctors now find diseases earlier and plan treatments more accurately. AI-powered vision systems help with image-guided surgeries, making procedures safer. One study showed that a model predicted patient deterioration 8-9 hours before ICU admission, improving outcomes by 22%. Another model forecasted treatment responses, supporting personalized medicine. These advances lead to better patient care and more precise diagnoses.

Security and Surveillance

Security and surveillance rely on real-time object detection and tracking. Time series machine vision systems analyze video feeds to spot unusual behavior or threats. They use real-time communication to alert security teams when something happens. These systems measure performance with precision, recall, F1 score, and AUC. On standard datasets, they achieve higher accuracy than older methods. Real-time monitoring helps teams track people or objects across many cameras. This technology keeps public spaces safer and supports quick responses to incidents.

Time series machine vision systems outperform traditional approaches in action recognition, quality inspection, and video surveillance. Their ability to process real-time data and provide instant feedback makes them essential in many industries.

Time series machine vision systems stand out because they analyze changes over time, not just single images. These systems help industries improve safety, quality, and decision-making. New trends show that smarter AI, better memory, and real-time processing will make these systems even more powerful.

- Limited Memory AI lets systems use recent data for better decisions.

- Edge computing and explainable AI help with faster and clearer results.

Machine vision with temporal analysis will keep growing and help solve more complex visual tasks.

FAQ

What is a time series machine vision system?

A time series machine vision system studies a sequence of images over time. It tracks changes and patterns, helping users understand how things move or change in real life.

How does it differ from traditional machine vision?

Traditional machine vision looks at single images. Time series machine vision examines many images in order. This helps the system spot trends, movements, or slow changes that one image might miss.

Where do people use time series machine vision systems?

People use these systems in factories, hospitals, and security centers. They help with quality checks, patient monitoring, and video surveillance.

What are the main challenges with these systems?

Time series machine vision systems need to handle lots of data. They require strong computers and special software to process images quickly and accurately.

See Also

Understanding The Role Of Cameras In Machine Vision

Comparing Firmware-Based And Traditional Machine Vision Systems

A Detailed Guide To Image Processing In Machine Vision

Explaining Computer Vision Models Within Machine Vision Systems