A regressor machine vision system uses advanced algorithms to predict continuous values directly from image data. These systems help industries measure, inspect, and control processes by analyzing visual information. Regression allows the system to estimate precise measurements, such as the size of an object or the depth in a scene. Companies rely on these systems to boost accuracy and efficiency. For example, inspection systems now achieve below 1% error rates and can reduce inspection time by 75%. The table below shows how accuracy and speed improve across different applications:

| Industrial Application | Metric | Numerical Evidence | Impact |

|---|---|---|---|

| Welding Defect Detection | Accuracy | 96.1% accuracy using ResNet-50 | High reliability in defect detection |

| AI-driven Inspection Systems | Error Rate | Below 1% error rate vs ~10% manual inspection | Significantly improved reliability |

| General Electric | Inspection Time | 75% reduction in inspection time | Faster quality control processes |

| Walmart | Inventory Turnover | 25% improvement | Increased operational efficiency |

The use of regression in these systems depends on strong data analysis. Metrics like mean squared error and R-squared measure how well the system predicts outcomes from images. These tools help companies reach better decisions with reliable data.

Key Takeaways

- Regressor machine vision systems predict precise measurements from images, helping industries improve accuracy and speed in tasks like inspection and quality control.

- These systems use advanced algorithms, feature extraction, and performance metrics to deliver reliable real-time predictions across various applications such as manufacturing, healthcare, and agriculture.

- Decision trees, support vector regression, and deep learning models like convolutional neural networks work together to boost system accuracy and handle complex visual data.

- High-quality data, proper preprocessing, and continuous model updates are essential to maintain accuracy and adapt to changing conditions in real-world environments.

- Future trends include better datasets, hybrid models, and real-time learning, which will enhance system performance and expand applications in robotics, autonomous vehicles, and more.

Regressor Machine Vision System

Definition

A regressor machine vision system uses regression to predict continuous values from images. This system combines cameras, sensors, and advanced algorithms to analyze visual data. Unlike classification, which sorts images into categories, regression estimates measurements such as length, weight, or color intensity. The system processes each image and applies a regression model to generate precise predictions. For example, a system can measure the size of fruit or detect subtle changes in color that indicate ripeness.

Researchers have shown that regression, when paired with machine vision, can accurately assess quality in real-world scenarios. In a recent study, scientists used multiple linear regression to detect damage in bananas during storage. They found that using the Lab* color space improved the determination coefficient, with R² values above 0.53, compared to less than 0.39 for RGB color space. This result means the system could better predict bruise damage and quality changes, proving that regression models can reliably assess external quality.

Core Purpose

The core purpose of a regressor machine vision system is to deliver accurate, real-time predictions for continuous variables in industrial and scientific applications. This system helps companies automate inspection, measurement, and monitoring tasks. By using regression, the system can estimate values like product weight, surface area, or even chemical concentration from images. These predictions support better decision-making and improve process control.

Feature extraction and selection play a key role in boosting system performance. Advanced methods, such as hybrid V-WSP-PSO, can reduce the number of features from thousands to just over a hundred, while still maintaining high predictive performance. For instance, a wrapper method combined with extreme gradient boosting achieved an RMSECV of 0.4013 MJ/kg and an RCV² of 0.9908, showing that the system can deliver high accuracy with fewer features.

Performance metrics help evaluate how well the system works. Metrics like mean absolute error (MAE), root mean squared error (RMSE), accuracy, precision, recall, and F1 score provide a complete picture of system performance. The table below summarizes these metrics and their business uses:

| Metric | Definition / Calculation | Business Goal Alignment / Use Case |

|---|---|---|

| MAE/RMSE | Measures prediction errors | Regression tasks such as sales or price prediction |

| Accuracy | Correct predictions / Total predictions | Balanced classes; image recognition |

| Precision | TP / (TP + FP) | Minimize false alarms; fraud detection |

| Recall | TP / (TP + FN) | Minimize missed cases; medical diagnosis |

| F1 Score | Harmonic mean of Precision and Recall | Balance both errors; general classification |

A regressor machine vision system adapts to changing data by using continuous evaluation. Cross-validation and monitoring for data drift ensure the system remains reliable over time. This approach allows industries to maintain high accuracy and efficiency, even as conditions change.

Note: Companies that use regressor machine vision systems often see faster inspections, fewer errors, and better product quality. These systems support a wide range of applications, from agriculture to manufacturing, by providing reliable, real-time predictions.

How They Work

Regression Models

A regressor machine vision system uses a series of steps to make real-time predictions from images. The process starts with data collection. The system gathers raw data from cameras or sensors. Data preprocessing comes next. This step cleans and normalizes the data, making it ready for analysis. Feature extraction follows, where the system finds important details in each image, such as edges, shapes, and textures. These features help the model understand what is in the image.

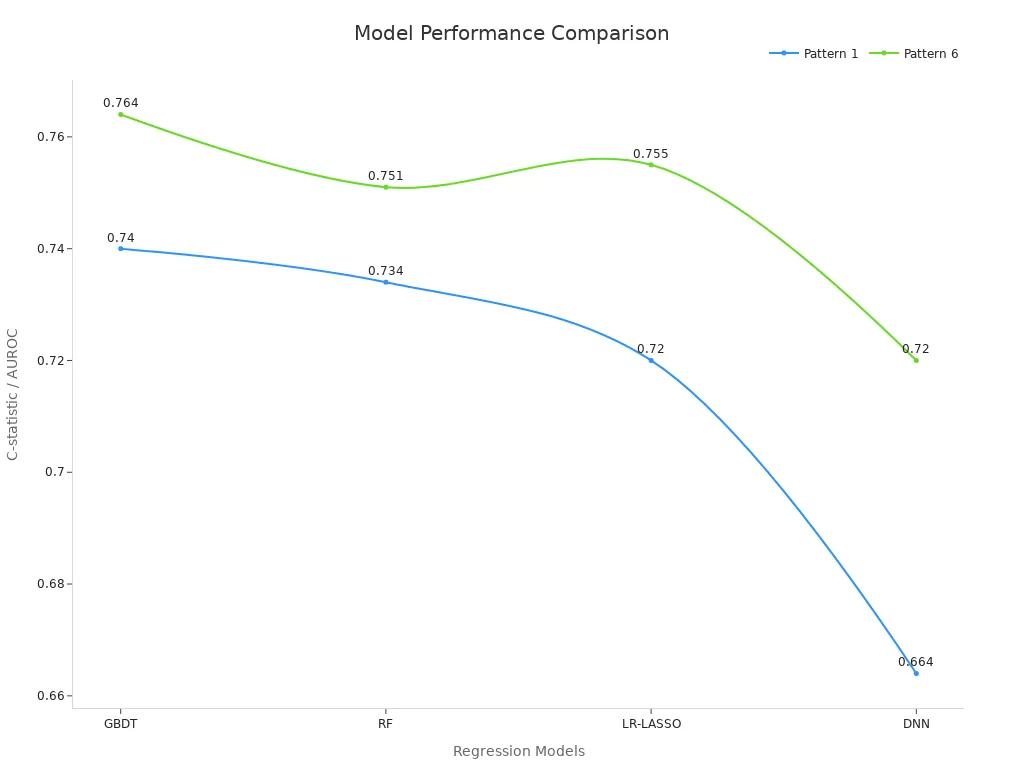

The system then uses a regression model to learn from the data. Common models include gradient boosting decision trees, random forests, and deep neural networks. Each model has strengths. For example, gradient boosting often gives the best accuracy, while deep neural networks handle complex patterns. The table below compares model performance using standard metrics:

| Data Pattern | Models Compared | Key Metric (AUROC) | Model Performance Ranking |

|---|---|---|---|

| Pattern 1 | GBDT, RF, LR-LASSO, DNN | GBDT: 0.740, RF: 0.734, LR-LASSO: 0.720, DNN: 0.664 | 1. GBDT, 2. RF, 3. LR-LASSO, 4. DNN |

| Pattern 6 | GBDT, LR-LASSO, RF, DNN | GBDT: 0.764, LR-LASSO: 0.755, RF: 0.751, DNN: 0.720 | 1. GBDT, 2. LR-LASSO, 3. RF, 4. DNN |

The system uses metrics like mean squared error, mean absolute error, and R-squared to measure accuracy. These metrics help compare models and choose the best one for real-time tasks. The system also uses cross-validation to check how well the model works on new data.

Visual Data Processing

Visual data processing is key for high accuracy in object detection and real-time predictions. The system starts with data preprocessing, which removes noise and enhances image quality. Feature extraction is the next step. The system uses algorithms like Sobel and Canny for edge detection, SIFT for local features, and HOG for object structure. Convolutional neural networks, built with tools like tensorflow and pytorch, learn features automatically from large datasets.

The system uses classification and regression for different tasks. For example, image classification sorts images into groups, while regression predicts continuous values. Object detection combines both, finding and measuring objects in real-time. Feature extraction helps the system find patterns in the data, improving accuracy and performance.

The visual data processing pipeline includes:

- Data ingestion from cameras or sensors.

- Data preprocessing to clean and normalize images.

- Feature extraction to find important details.

- Model training using machine learning techniques.

- Model evaluation with performance metrics.

- Model deployment for real-time predictions.

- Monitoring and maintenance to keep the system accurate.

Note: The system uses real-time tasks to support applications like object detection, image classification, and classification and regression. Feature extraction and regression models work together to deliver high accuracy and fast predictions.

Key Technologies

Decision Tree Machine Vision System

A decision tree machine vision system uses a tree-like structure to make decisions from visual data. The system splits data into branches based on features like color, shape, or size. Each branch leads to a decision or prediction. This model works well for object detection and quality checks. The system can handle both simple and complex datasets. Decision trees help the system find patterns in data and improve performance. They also support real-time predictions by making fast decisions. Many industries use decision tree machine vision systems for tasks like sorting products or finding defects. The system can combine many trees to form a random forest, which boosts accuracy and reduces errors.

Support Vector Regression

Support vector regression (SVR) is another model used in machine vision systems. SVR finds the best line or curve that fits the data. The system uses SVR to predict values like size, weight, or color intensity from images. SVR works well with small or medium datasets and can handle noisy data. The model uses kernel functions to map data into higher dimensions, which helps the system find complex patterns. SVR supports high accuracy in tasks like measuring parts or checking surface quality. The system often combines SVR with feature extraction to improve performance metrics and accuracy.

Hardware and Software

The hardware and software in a machine vision system play a key role in performance. Cameras and sensors collect data for the system. Monochrome cameras give better edge detection and contrast, which helps with surface defect detection. Sensor resolution changes by application: 1-5 MP for defect detection, 2-12 MP for assembly checks, and 5-20 MP for precise measurements. Frame rates range from 10 fps for assembly to 200 fps for fast inspections. Bit depth matters for accuracy, with 12-bit for contrast and 16-bit for subtle defects. Global shutter cameras prevent motion blur in moving objects. Specialized sensors, like near-infrared or hyperspectral, help with material sorting and analysis. The system must meet environmental and compliance needs, such as IP67 ratings or FDA rules.

Hardware choices affect system performance. Processor speed, GPU or TPU use, memory, and storage all impact how fast the system can process data and run models. AI and machine learning techniques improve defect detection and adaptability. Regular calibration and maintenance keep the system accurate. The system uses real-time processing interfaces and connects with robotic controls for automation. Software algorithms, including convolutional neural networks built with tensorflow and pytorch, support both classification and regression tasks. Data preprocessing and feature extraction help the system handle large datasets and improve accuracy.

Applications

Quality Assessment

Many industries use computer vision for quality assessment. A regressor machine vision system helps companies find defects and measure product quality with high accuracy. In manufacturing, AI-driven visual inspection systems reduce product deviations by more than 50%. They also cut waste by 75% and allow 25% of workers to focus on higher-value tasks. These systems provide instant and consistent defect detection across production lines, which improves traceability and lowers defect rates. Most manufacturers now invest in digital quality assurance tools, with technology spending expected to reach 30% of operating budgets. This shift shows the value of high accuracy and efficiency in quality control.

AI-powered computer vision systems enhance product quality, lower costs, and boost operational efficiency. Companies see fewer errors and better results when they use these systems for quality assessment.

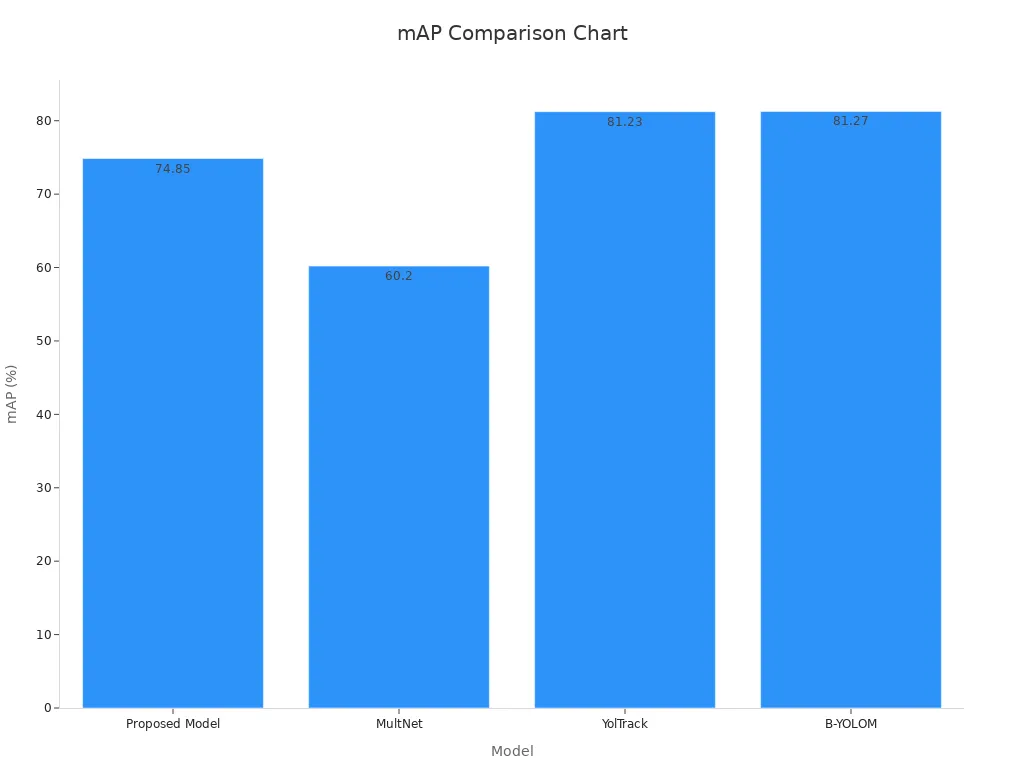

3D Localization

Regressor machine vision systems play a key role in 3D localization tasks. These systems use computer vision to find the exact position and orientation of objects in space. Accuracy is measured by how close the system can localize images within strict pose error thresholds, such as (0.1m, 1.0°). The average relative rotation error (RRE) gives a clear metric for orientation accuracy. High accuracy in 3D localization supports real-time tasks like robot navigation and automated assembly. Metrics such as Intersection over Union (IoU) and mean Average Precision (mAP) help evaluate how well the system detects and localizes objects. These performance metrics ensure reliable results, even in complex environments.

Computer Vision in Industry

Computer vision transforms many sectors by improving accuracy and performance. In healthcare, AI-assisted computer vision helps radiologists detect cancer faster and with higher accuracy. In manufacturing, computer vision systems find small defects in brake parts with over 95% accuracy, which surpasses human inspectors. Agriculture uses these systems to sort crops and monitor growth, leading to better yields and less waste. Automotive companies use computer vision for real-time object detection and 3D localization, making self-driving cars safer. The market for computer vision reached $15.9 billion in 2023 and continues to grow as more industries seek high accuracy and efficiency. Real-time analytics and advanced AI algorithms drive this growth, helping companies make better decisions and improve safety.

| Sector | Application Example | Accuracy Improvement | Performance Benefit |

|---|---|---|---|

| Healthcare | Cancer detection | Faster, more accurate | Better patient outcomes |

| Manufacturing | Brake part defect detection | Over 95% accuracy | Fewer recalls, less waste |

| Agriculture | Crop sorting and monitoring | High accuracy in grading | Higher yields, less waste |

| Automotive | Self-driving car localization | High accuracy in 3D tasks | Improved safety, reliability |

Challenges and Trends

Implementation Issues

Many companies face challenges when they use a regressor machine vision system. One major issue is the need for large amounts of data. Over 42% of industry leaders say that a lack of enough data is the biggest problem. Too much data can also slow down the system and make real-time predictions harder. High costs and the need for domain experts add to the challenge.

Image quality can affect accuracy. Variations in brightness or contrast from different cameras or microscopes can change model predictions. Without standard data preprocessing, the system may not reach high accuracy. Different feature extraction methods, such as BSIF or VLAD, need different amounts of data and can change model performance. Overfitting is another problem. If a model learns too much from training data, it may not work well on new images.

Note: Companies often use performance metrics like Mean Absolute Percentage Error (MAPE) to check how well a model predicts. These metrics help spot problems with accuracy and guide improvements.

Annotation quality also matters. Bounding boxes and IoU thresholds help with object detection, but errors in labeling can lower accuracy. Automated annotation tools with human review can improve data quality and boost model performance.

Future Directions

The future of regressor machine vision systems looks promising. Researchers focus on building better datasets to improve accuracy and make results more reliable. Multi-task and multi-modal learning will help systems handle complex problems, such as detecting many defects at once or using data from different sensors. Small sample learning, like transfer learning and meta-learning, will help models work well even with limited data.

Advances in hardware, such as GPUs, TPUs, and quantum computing, will allow faster real-time predictions and more complex models. Hybrid models that combine decision trees with deep learning, such as convolutional neural networks built with tensorflow and pytorch, will improve both accuracy and interpretability. Real-time online learning will let systems adapt to new data and changing environments.

Tip: Companies should focus on continuous model updates and adaptive algorithms to keep up with new data and improve training accuracy.

AI-driven robotics and 3D computer vision will become more common, especially in industries like autonomous vehicles and healthcare. These trends will push for higher accuracy, better performance, and more reliable predictions. As the field grows, new machine learning techniques and better performance metrics will help companies reach their goals for accuracy improvement and real-time tasks.

A regressor machine vision system uses data, regression, and machine learning techniques to deliver high accuracy in real-time predictions. These systems rely on feature extraction, data preprocessing, and performance metrics to improve accuracy. Many industries use computer vision for object detection, image classification, and classification and regression. Accuracy matters in every step, from dataset creation to model training. Decision tree machine vision system and convolutional neural networks built with tensorflow and pytorch help boost accuracy. Real-time tasks need accuracy improvement and strong performance. Companies measure accuracy with metrics and focus on training accuracy. Future models will use better data and aim for even higher accuracy.

Ongoing advancements in AI, real-time systems, and performance metrics will create new opportunities for accuracy improvement and reliable predictions.

FAQ

What is a regressor machine vision system?

A regressor machine vision system uses computer vision and regression models to predict continuous values from images. The system relies on data preprocessing, feature extraction, and machine learning techniques to achieve high accuracy in real-time predictions for tasks like quality assessment and object detection.

How does a decision tree machine vision system work?

A decision tree machine vision system splits data into branches based on features found in images. The model uses these splits to make predictions or decisions. This approach helps with classification and regression, supporting real-time tasks and accuracy improvement in many industries.

Why is high accuracy important in computer vision?

High accuracy ensures that the system makes reliable predictions. In applications like image classification, object detection, and real-time tasks, accuracy improvement leads to better performance, fewer errors, and safer outcomes. Companies use performance metrics to measure and improve training accuracy.

What role do convolutional neural networks play in machine vision?

Convolutional neural networks, often built with tensorflow and pytorch, help the system learn patterns from large datasets. These models support both classification and regression tasks. They improve performance by automating feature extraction and boosting real-time predictions in computer vision applications.

How do companies ensure good performance in real-time predictions?

Companies use data preprocessing, feature extraction, and performance metrics to monitor system performance. They train models with high-quality datasets and update them regularly. AI and machine learning techniques help maintain training accuracy and support accuracy improvement for real-time predictions.

See Also

Understanding How Machine Vision Systems Process Images

Comparing Firmware-Based And Traditional Machine Vision Systems

A Detailed Look At Electronics In Machine Vision Systems