A prior machine vision system helps you automate tasks by capturing images, analyzing data, and making decisions. You see these systems use image acquisition, data delivery, information extraction, and decision making as their core features. In the early days of machine vision technology, accuracy, precision, and speed measured how well each machine vision system worked. These features let you spot product changes instantly, keep visual records, and improve automation. Understanding these key features shows how machine vision shaped modern automation and safety.

Here’s how performance was measured in early machine vision:

Metric Purpose Accuracy Correctly classifies images Precision Detects true positives IoU Measures object overlap F1-score Balances precision and recall

Key Takeaways

- Prior machine vision systems capture and analyze images to automate tasks like product inspection and robot guidance.

- These systems rely on four main steps: image acquisition, data delivery, information extraction, and decision making.

- Early machine vision improved accuracy and speed but needed controlled lighting and expert setup to work well.

- Better data delivery and information extraction helped reduce downtime, lower costs, and speed up inspections.

- Despite challenges like high costs and environmental sensitivity, early machine vision paved the way for today’s smarter, AI-driven systems.

Machine Vision Overview

What Is Machine Vision?

You use a machine vision system to help machines see and understand the world. Machine vision gives computers the ability to capture images, process them, and make decisions based on what they see. In automation, this means you can inspect products, guide robots, and control processes without human eyes. A machine vision system uses cameras and sensors to collect image data. Algorithms then analyze this data to find defects, measure parts, or track objects.

Machine vision technology plays a big role in computer vision, which is the broader field that teaches computers to interpret visual information. You find machine vision in many industries because it improves quality and speed. For example, a machine vision system can spot tiny scratches on a product or check if a label is in the right place. This reduces errors and saves time.

Machine vision systems collect and analyze statistical data from images. They use this data to improve quality control, measure dimensions, and guide robots. The table below shows how machine vision supports different functions in automation:

| Function Area | Description | Statistical Data Role |

|---|---|---|

| Defect Inspection | Detects scratches, cracks, or missing parts | Identifies defects and reduces manual inspection errors |

| Dimension Measurement | Measures product size and tolerance | Ensures products meet standards |

| Assembly Guidance | Locates components for automated assembly | Prevents assembly errors and rework |

| Robotics Control | Tracks objects for precise robotic movement | Enables safe and accurate operation |

| Inventory Management | Reads barcodes and sorts items | Tracks inventory and improves sorting accuracy |

Early Development

Machine vision technology first appeared in the 1970s and 1980s. You saw early machine vision systems in factories where they checked parts and guided simple robots. These early systems used basic cameras and simple computer vision algorithms. Lighting and image quality mattered a lot because computers needed clear pictures to work well.

During this time, you watched machine vision become a key part of industrial automation. Early machine vision systems helped companies inspect products faster and with fewer mistakes. They also made workplaces safer by taking over dangerous inspection tasks. As computer vision improved, machine vision technology became more reliable and flexible. You now see machine vision in many industries, from food processing to electronics.

Core Features of Prior Machine Vision Systems

Image Acquisition

You start with image acquisition when you use a prior machine vision system. This step lets your machine vision system capture clear images of objects or scenes. Early systems used black-and-white cameras, optical lenses, and structured lighting to get the best possible images. You might see a setup with a camera above a conveyor belt, shining bright lights to reduce shadows and highlight defects. The quality of image acquisition affects everything that comes after. If your images are blurry or too dark, your machine vision system cannot perform accurate detection or object recognition.

You rely on image acquisition to collect data for computer vision tasks. Early machine vision systems often used simple sensors and basic ai image processing to enhance image clarity. You might use image acquisition three times in a single inspection cycle: first to capture the initial product, next to check for defects, and finally to verify the finished item. This process supports barcode reading, character recognition, and pattern matching. Good image acquisition helps your machine vision system reach high accuracy and reliable results.

Data Delivery

After you capture images, your machine vision system needs to deliver data quickly and reliably. Data delivery moves information from the camera to the computer or controller. In a prior machine vision system, you often used wired connections and simple protocols. Early advances in data delivery, such as faster cables and better interfaces, helped you reduce downtime and improve efficiency.

You can see how improvements in data delivery made a big difference in manufacturing. For example, when you use real-time data delivery, you can spot problems faster and fix them before they cause delays. Early machine vision systems, enhanced by ai and IoT, allowed you to monitor equipment and predict failures. This proactive approach led to big savings and less downtime.

The table below shows how better data delivery improved performance in early machine vision systems:

| Improvement Metric | Statistical Evidence |

|---|---|

| Downtime reduction | Up to 50% |

| Maintenance cost savings | Between 15% and 30% |

| Increase in equipment uptime | Between 20% and 30% |

| Inspection time reduction (automotive) | 70% reduction |

| Annual savings (automotive) | $20 million |

| Reduction in downtime (automotive) | 15% |

| Cost savings compared to preventive maintenance | 8% to 12% |

| Cost savings compared to reactive maintenance | Up to 40% |

You see that better data delivery in a machine vision system means faster inspections, lower costs, and more reliable production.

Information Extraction

Once your machine vision system delivers the image data, it must extract useful information. Information extraction is the process where your system finds and pulls out important details from images. In a prior machine vision system, you often used feature extraction, ai image processing, and computer vision algorithms to identify shapes, edges, or text. You might use information extraction to read a barcode, measure a part, or check for missing pieces.

You face many challenges with information extraction in early machine vision. Historical documents, like well records, often exist as scanned images or paper copies. Manual extraction takes a lot of time and skill. You need accurate information for tasks like finding well locations or measuring depths. Combining optical character recognition with large language models helps automate this process, making data editable and searchable. The design of prompts and the size of models affect how well your system extracts information. Better workflows speed up large-scale data collection and support research.

- Manual extraction from historical records is slow and needs experts.

- Documents come in many formats, often as images or paper.

- Accurate location and depth data are important for safety and the environment.

- Using OCR and large models automates extraction and makes data easy to search.

- The way you design prompts and choose model size changes extraction accuracy.

- Good text conversion is key, so better OCR and multi-modal models help a lot.

- Automated extraction speeds up plugging abandoned wells and helps research.

You depend on information extraction to turn raw images into useful data for your machine vision system.

Decision Making

The final step in a prior machine vision system is decision making. Your machine vision system uses the extracted information to make choices, such as accepting or rejecting a product. Decision-making relies on computer vision, ai, and specific algorithms to compare results against set standards. You might use decision making to trigger alarms, stop a machine, or sort items on a conveyor.

You measure the reliability of decision making by checking accuracy and efficiency. Regular audits help you review how well your system works. You compare performance to benchmarks and watch for drops in accuracy. Early detection of problems keeps your machine vision system reliable. You use audit results to improve your system and make better decisions in the future.

- You review system performance data often.

- You compare results to benchmarks.

- You track accuracy and efficiency metrics.

- You spot problems early to keep your system reliable.

- You use audit findings to improve decision making.

Decision making in a machine vision system lets you automate quality control, reduce errors, and boost productivity. You see how ai, computer vision, and decision-making algorithms work together to make your prior machine vision system smarter and more effective.

Performance Impact

Industrial Applications

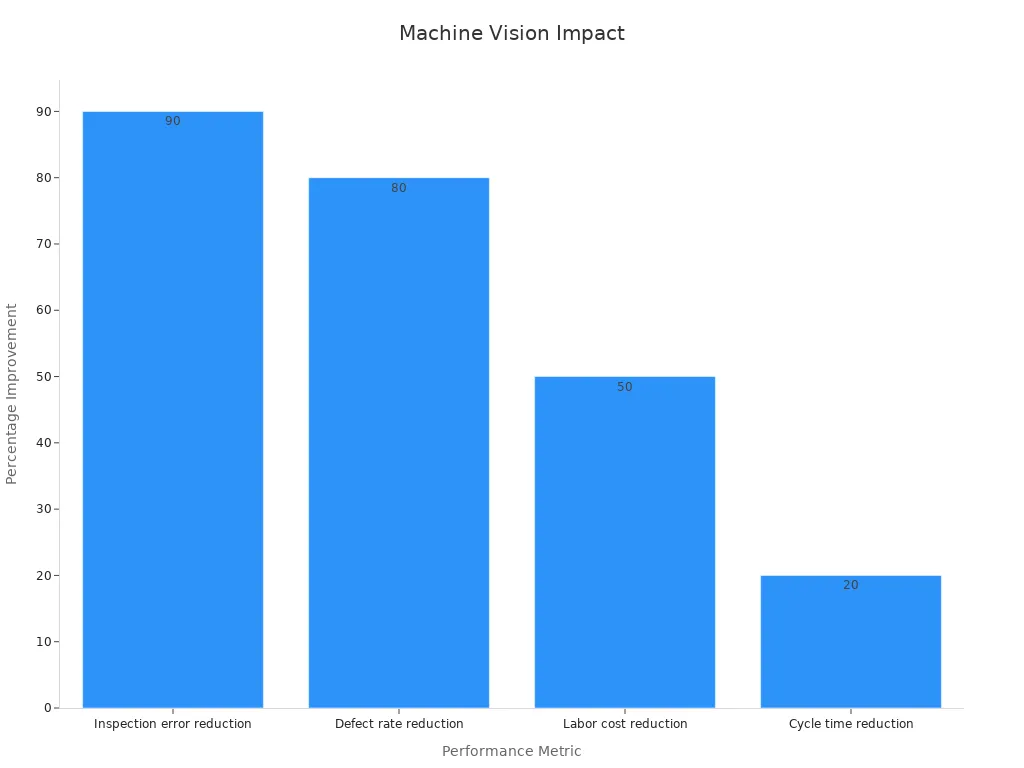

You see machine vision systems change how you work in industrial automation. When you use these systems in manufacturing applications, you boost accuracy and speed. For example, you can inspect products much faster than with manual checks. You also reduce errors and improve quality. In factories, you use automation to spot defects, measure parts, and guide robots. This leads to fewer mistakes and higher efficiency.

Machine vision helps you save money and time. You cut labor costs and make production cycles faster. You also improve quality by catching more defects before products leave the factory.

Here is how machine vision impacts your work:

| Performance Metric | Impact Description |

|---|---|

| Inspection error reduction | Over 90% decrease compared to manual inspection |

| Defect rate reduction | Up to 80% fewer defects |

| Labor cost reduction | About 50% less spent on quality assurance labor |

| Cycle time reduction | Up to 20% faster production cycles |

You use advanced technologies like 3D vision and hyperspectral imaging to reach high accuracy. These tools help you measure parts down to 0.005 mm and analyze materials in detail. You also see economic benefits, such as lower installation costs and less rework.

Reliability Challenges

You face some challenges when you use early machine vision systems. You need controlled lighting to get clear images. If the lighting changes, your accuracy drops and your inspection results suffer. You often adjust cameras and lights to keep quality high. This takes time and can slow down automation.

You also deal with system errors. Sometimes, your machine vision system gives false positives or misses defects. You must check results often to keep quality and efficiency at their best. You use repeatable tests, like the golden sample method, to make sure your system stays accurate. High-quality imaging and good software help you meet strict industry standards.

Tip: Regular audits and system checks help you catch problems early and keep your automation running smoothly.

You see that as you improve your machine vision system, you get better accuracy, higher quality, and more reliable automation in your manufacturing applications.

Evolution of Machine Vision Technology

From Classic to Modern Systems

You have seen machine vision change a lot over the years. In the past, you worked with simple cameras and basic ai image processing. Early machine vision systems needed perfect lighting and careful setup. You often spent hours adjusting equipment to get good results. Now, you use advanced machine vision technology that works in many environments. You can rely on deep learning, smart sensors, and fast processors. These tools help you handle complex tasks with less effort.

Modern machine vision systems use ai and automation to make your work easier. You can set up a system quickly and let it learn from data. You do not need to write code or adjust every setting. The integration of new hardware, like GPUs and NPUs, gives you more speed and power. You can process images in real time and make decisions faster. This shift from classic to modern systems means you spend less time on setup and more time improving your process.

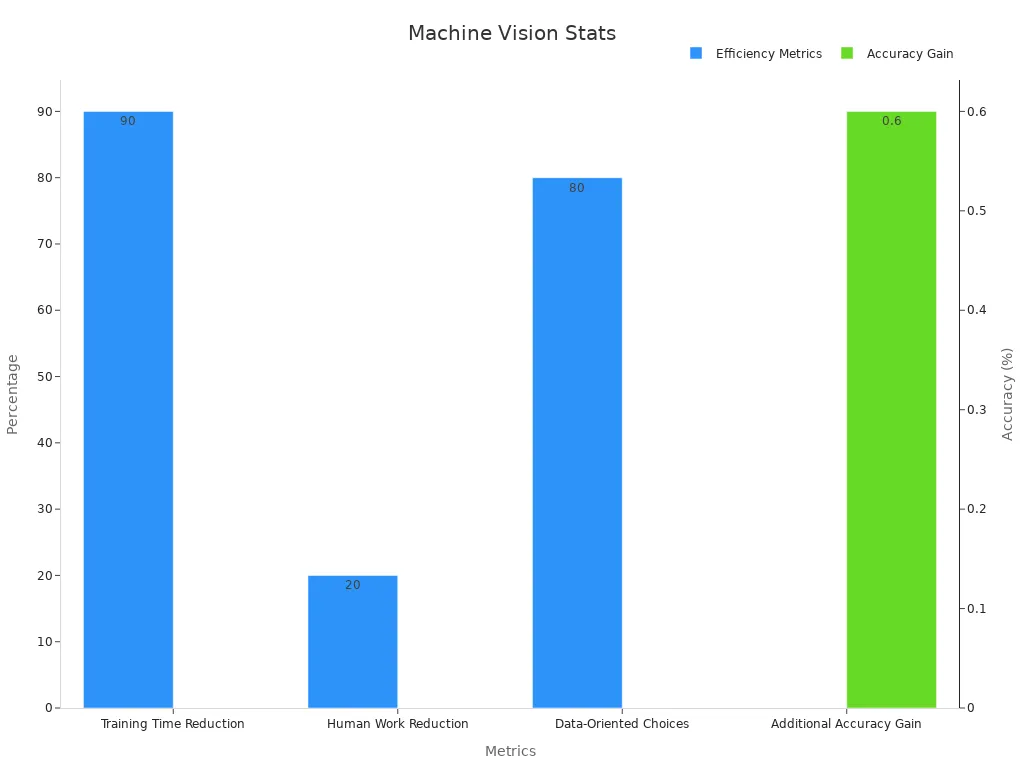

Key Advancements

You benefit from many advancements in machine vision technology. Algorithms now learn from large datasets and improve accuracy. You use ai image processing to spot tiny defects and measure parts with high precision. Automation lets you focus on important tasks while the system handles routine checks. Integration with other systems, like robotics and cloud platforms, boosts your efficiency.

Today, you can use no-code solutions to build machine vision applications. This makes the technology easy for everyone, not just experts.

You see big improvements in hardware. GPUs and TPUs help you train models faster, but they use a lot of energy. NPUs give you fast processing with less power, which is great for mobile and edge devices. You can now automate model selection and feature processing, saving you time and reducing errors.

| Metric | Numerical Data | Description |

|---|---|---|

| Training Time Reduction | Up to 90% | Transfer learning speeds up training while keeping high accuracy |

| Human Work Reduction | 20% | Automation cuts human effort to just 20% of the work |

| Data-Oriented Choices | 80% | 80% of tasks now use data-driven decisions |

| Accuracy Improvement | 0.2% – 0.6% | New methods boost accuracy by up to 0.6% |

| Automated Model Selection | Enabled | Systems now pick models and settings automatically |

| Automated Feature Processing | Enabled | Feature processing is now automatic |

You notice that integration with automation and ai makes your workflow smoother. Machine vision technology now helps you improve quality control, speed up production, and reduce mistakes. You can use 3D imaging and vision-guided robotics for even more advanced tasks. These changes make machine vision a key part of modern industry.

Limitations of Prior Systems

Technical Constraints

You face many technical challenges when you use prior machine vision systems. These systems often need a high initial investment. You pay not just for cameras, but also for image processors, lighting, environmental controls, software, and support. Custom development for unique tasks increases your costs even more. You must spend time and money on setup and calibration. You need to tune lenses, lighting, and system parameters with great care. Reflective surfaces make things harder because you must adjust lighting to avoid glare and distortion.

Machine vision systems are sensitive to their environment. Changes in lighting, vibrations, temperature, or dust can lower accuracy. You often need a controlled environment to keep accuracy and quality high. This adds to your expenses. Shiny or transparent objects are hard for 3D sensors to process, which causes detection errors and reduces accuracy. You depend on skilled personnel for configuration, maintenance, and troubleshooting. The shortage of ai and computer vision experts makes hiring difficult. Sometimes, you must rely on external vendors, which raises long-term costs.

- High initial investment covers hardware, software, and integration.

- Complex setup and calibration require expert knowledge.

- Environmental sensitivity affects accuracy and quality.

- Shiny or transparent objects challenge 3D sensors.

- Skilled personnel are needed for maintenance and troubleshooting.

Adoption Barriers

You also face barriers when you try to adopt early machine vision systems. High costs stop many small businesses from using this technology. Expensive hardware and software, along with integration challenges, make adoption difficult. Customization needs increase development time and reduce profitability. You may depend on imported components, which raises production costs and limits how much you can scale.

Many users lack awareness of how machine vision and ai can improve automation and quality. The complexity of these systems means you need specialized knowledge for setup and maintenance. These systems often lack flexibility, so you must make big adjustments to handle new tasks. Technical barriers limit domestic hardware development, which affects your competitiveness. You often need a controlled environment to keep accuracy high, which increases costs even more.

Note: Overcoming these barriers requires better training, lower costs, and easier integration with existing automation systems.

| Limitation | Impact on Adoption |

|---|---|

| High initial investment | Limits access for small businesses |

| Complex integration | Slows down deployment |

| Environmental sensitivity | Reduces accuracy and quality |

| Lack of awareness | Slows adoption of automation and ai |

| Need for experts | Increases long-term costs |

You see how early machine vision systems changed the way you work in factories and technology. These systems brought high accuracy, fast inspections, and less downtime. Today, you benefit from this progress as the global computer vision market grows quickly.

| Metric | Value/Projection | Impact |

|---|---|---|

| Defect detection accuracy | Over 99% | High precision |

| Manufacturing downtime | 25% reduction | More efficiency |

| Inspection speed | Hundreds per minute | Faster production |

| Market size (2028) | Over $45 billion | Rapid growth |

Understanding these features helps you appreciate how far machine vision has come and how past challenges shaped today’s smart systems.

FAQ

What makes a prior machine vision system different from modern systems?

You use older machine vision systems with basic cameras and simple algorithms. Modern systems use AI, deep learning, and advanced sensors. You get more accuracy and flexibility with new technology.

Why did early machine vision systems need controlled lighting?

You need controlled lighting because early systems could not handle shadows or glare. Good lighting helps your system capture clear images. This improves accuracy and reduces errors.

How did you measure the success of a machine vision system in the past?

You measured success by checking accuracy, speed, and reliability. You looked at how well your system found defects and how fast it inspected products.

Tip: Regular checks help you keep your system working well.

What were the biggest challenges with early machine vision systems?

You faced high costs, complex setup, and the need for expert help. You also had trouble with changing environments and shiny or transparent objects.

- High cost

- Complex setup

- Need for experts

See Also

Comparing Firmware-Based Vision With Conventional Machine Systems

Essential Features And Advantages Of Medical Machine Vision Devices

Understanding How Image Processing Powers Machine Vision Systems

Exploring Computer Vision Models And Their Role In Machine Vision