When you use a machine vision system, recall helps you see how well the system finds all the important objects or defects. In computer vision, recall shows the percentage of real things the system detects. For example, if a Recall machine vision system finds 43 true positives and misses 7, recall equals 0.86. This means it catches 86% of what matters.

| Metric | Value | Explanation |

|---|---|---|

| True Positives (TP) | 43 | Correctly identified positive cases |

| False Negatives (FN) | 7 | Positive cases missed by the model |

| Recall | 0.86 | TP / (TP + FN), measures sensitivity or true positive rate |

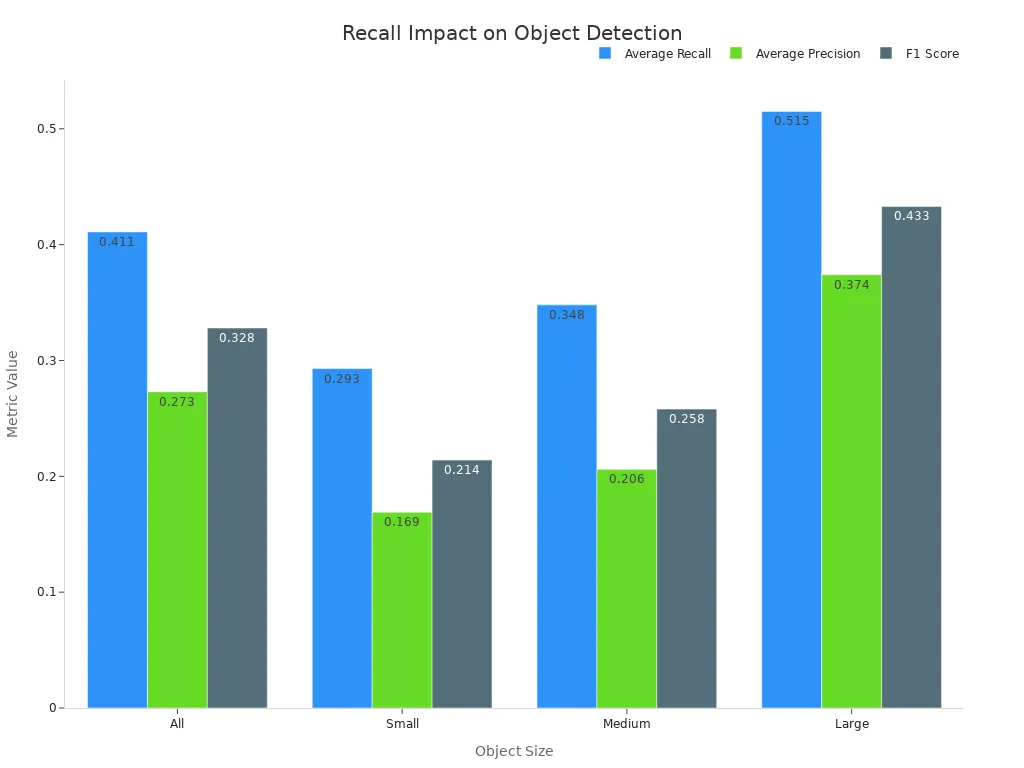

A high recall makes your machine vision system more reliable. You can see how recall changes with object size and lighting in real-world computer vision tasks. The chart below shows that better recall leads to stronger detection, especially for larger objects.

Key Takeaways

- Recall measures how well a machine vision system finds all real objects or defects it should detect.

- High recall means the system misses fewer important items, making it more reliable and safer.

- You calculate recall by dividing true positives by the sum of true positives and false negatives.

- Improving recall helps catch more defects, speeds up inspections, and lowers costs in real-world tasks.

- Balancing recall with precision is key to reducing missed objects without causing too many false alarms.

Recall Machine Vision System

What Is Recall?

You can think of recall as a way to measure how well a recall machine vision system finds all the important things it should detect. In machine vision, recall is also called sensitivity or true positive rate. This means it checks how many real objects or defects the system finds out of all the ones that actually exist. If your system misses some, recall goes down. If it finds almost everything, recall goes up.

For example, in object detection, recall tells you how many real objects your system finds in an image. If you have five apples in a picture and your system finds four, recall is 80%. This helps you see if your machine vision system is missing anything important.

Recall is very important in computer vision tasks where missing a defect or object can cause problems. In quality control, you want to catch every faulty product. In fire detection, you want to spot every sign of fire. Recall helps you measure this ability.

Tip: Recall is calculated as:

Recall = True Positives / (True Positives + False Negatives)True Positives are the things your system finds correctly. False Negatives are the things it misses.

Why Recall Matters

You need high recall in a recall machine vision system to make sure you do not miss any important defects or objects. Missing a defect can lead to faulty products reaching customers. Missing a fire can cause danger. High recall means your system catches almost everything it should.

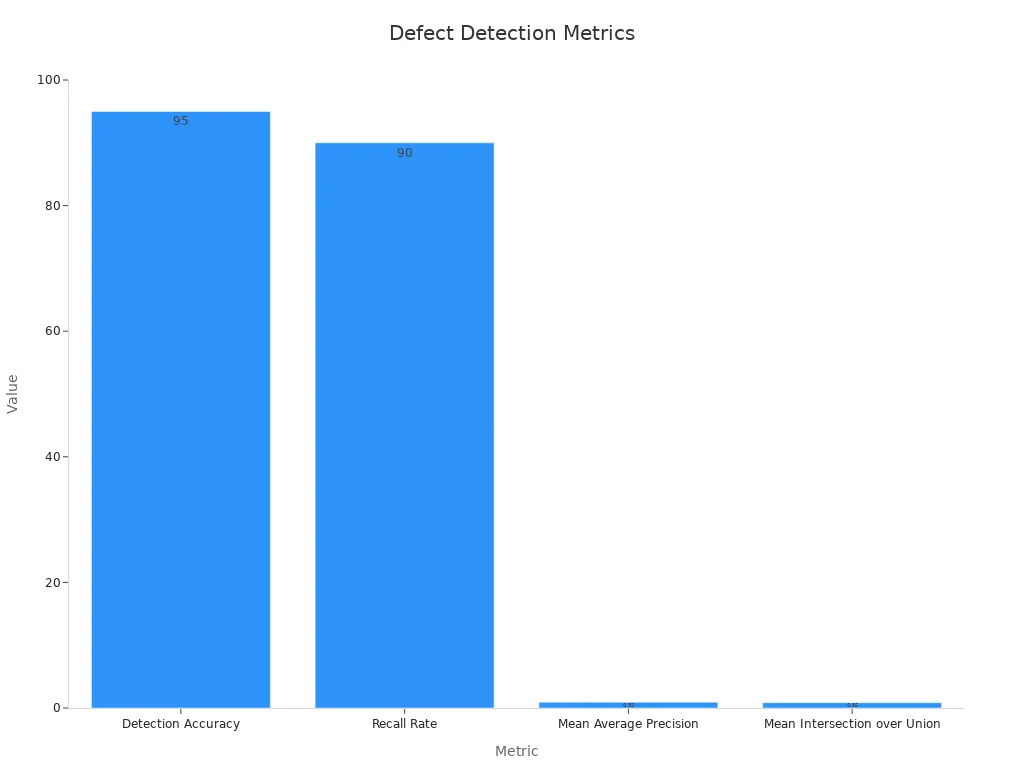

In real-world machine vision system applications, recall plays a big role in system reliability. For example, in quality control, a recall machine vision system can inspect 1,000 items and correctly find 986 defective ones. This gives you a recall of 99.4%. High recall helps you reduce missed defects and improve product quality.

Many industries use recall to check how well their systems work. In manufacturing, recall helps you catch bad parts before they leave the factory. In the automotive industry, recall machine vision systems find defects in car parts, like holes in bumper beams. This helps you fix problems early and avoid costly mistakes.

Here are some real-world results that show the power of high recall in machine vision:

- A deep learning model called YOLO-v3 with MobileNet found defects in electronic parts quickly and accurately. Data tricks like blurring and changing brightness helped the model reach high recall, even with little training data.

- Some systems reach recall rates of up to 100%, meaning they find every defect. This leads to less downtime and less waste in factories.

- Lightweight models allow for real-time inspection, which is important for fast-moving production lines.

- In bearing fault detection, using more training data and smart models improved recall and accuracy, even with small datasets.

Note: High recall is not just about finding more defects. It also means your system works well at high speeds and with different types of defects. This keeps your production line running smoothly.

| Metric | Before AI-powered Machine Vision | After AI-powered Machine Vision | Improvement Description |

|---|---|---|---|

| Defect Detection Accuracy | N/A | 99.8% | Achieved near-perfect defect detection accuracy |

| Inspection Time per Blade | 45 minutes | 3 minutes | Inspection time reduced by ~93% |

| Production Throughput | N/A | 15x increase | Number of blades inspected increased 15-fold |

| Labor Cost per Blade | N/A | Reduced by ~93% | Significant cost savings per blade inspected |

You can see that high recall in a recall machine vision system leads to better accuracy, faster inspections, and lower costs. These improvements help companies deliver safer and higher-quality products.

Recall Calculation

Confusion Matrix

You can use a confusion matrix to see how well your machine vision system works. This table shows how your model makes predictions. It breaks down the results into four groups:

| Component | Description |

|---|---|

| True Positive (TP) | The model correctly finds a real object |

| False Negative (FN) | The model misses a real object |

| False Positive (FP) | The model finds something that is not real |

| True Negative (TN) | The model correctly ignores a non-object |

A confusion matrix helps you understand the strengths and weaknesses of your system. You can see how many real objects your model finds and how many it misses. This breakdown is important for measuring recall, especially when you want to improve model performance in tasks like fault detection or medical diagnosis. Many teams in computer vision use the confusion matrix to check if their models miss important cases or make too many mistakes.

Note: The confusion matrix is a trusted tool in both research and industry. It helps you adjust your system to reduce costly errors and improve reliability.

Formula and Example

You can calculate recall using this simple formula:

Recall = True Positives / (True Positives + False Negatives)

This formula tells you the percentage of real objects your model finds. If your model finds most of the real objects, recall will be high. This is key for model performance, especially when missing a defect or object is risky.

Let’s look at a step-by-step example:

- Imagine you have 100 real defects in your dataset.

- Your model correctly finds 90 of them (True Positives).

- It misses 10 defects (False Negatives).

- Plug these numbers into the formula:

Recall = 90 / (90 + 10) = 90 / 100 = 0.9

So, your recall is 0.9, or 90%. This means your model finds 90% of all real defects. In computer vision, this high recall shows your system does not miss many important cases. You can use this method for both simple and complex datasets. Many experts also use recall along with other metrics, like precision and the F1 score, to get a full picture of model performance.

Object Classification

Impact of Recall

When you use object classification in computer vision, recall plays a big role in how well your system finds all the right objects. High recall means your model detects most or all of the objects you care about, like finding every red ball in a group. This is important in places like factories, where missing even one dangerous item can cause problems.

- Recall measures how many real objects your model finds compared to how many actually exist.

- High recall helps you avoid missing important objects, which are called false negatives.

- In industrial machine vision, missing an object can be critical, so you want your model to have high recall.

- There is a trade-off between recall and precision. If you focus only on recall, you might get more false alarms, but you will miss fewer real objects.

- The F1 score helps you balance recall and precision, giving you a single number to check overall model performance.

If you use a multi-class classifier, recall tells you how well your model finds each type of object. For example, if your model finds 90 out of 100 apples but misses 10, your recall for apples is 90%. High recall improves object classification accuracy by making sure you do not miss many true objects.

Remember: High recall means better coverage of true positives, which can boost your model’s accuracy and reliability.

Reducing False Negatives

You want to reduce false negatives because missing real objects can lead to mistakes. Recall shows you how well your model avoids these misses. For example, if your model has a recall of 0.6 on 10 positive samples, it finds 6 and misses 4. If you improve recall to 1.0, your model finds all 10 and misses none.

You can use several strategies to reduce false negatives and increase recall:

- Adjust the decision threshold in your model. Lowering the threshold can help your model catch more real objects, but it may also increase false positives.

- Try cost-sensitive learning, which gives more weight to important or rare classes.

- Use data techniques like oversampling or undersampling to balance your dataset.

- Tune your model’s parameters and choose the right features to help your model learn better.

These steps help you get high recall, which means your object classification system will miss fewer real objects. In many real-world tasks, like medical tests or safety checks, reducing false negatives is more important than avoiding false alarms.

Tip: Always check your recall score when you want to make sure your model does not miss anything important.

Precision vs Recall

Precision Explained

You often hear about precision vs recall when you measure how well a machine vision system works. Precision tells you how many of the items your system marked as positive are actually correct. In other words, precision checks if your system makes few mistakes when it says something is important. You want high precision when you need low false positives. For example, if your system finds 100 objects and 95 are correct, your precision is 95%.

Precision uses this formula:

Precision = True Positives / (True Positives + False Positives)

This formula shows that precision focuses on the accuracy of positive predictions. Studies using vehicle datasets show that precision can reach higher values than recall, especially when you adjust the system to be more careful. Precision can change a lot depending on how you set your model’s threshold. The precision-recall curve helps you see how these two metrics change together. In some cases, precision has a wider range than recall, which usually stays more stable.

When to Prioritize Each

You should choose between precision and recall based on what matters most in your project. If you want to avoid false alarms, focus on precision. For example, in fraud detection, you want to avoid marking real transactions as fraud. High precision means fewer customers get annoyed by mistakes. In product recommendations, high precision keeps users happy by showing only relevant items.

Sometimes, recall is more important. In medical tests, missing a disease can be dangerous. You want your system to catch every possible case, even if it means more false alarms. In cybersecurity, high recall helps you spot every threat, even if some are not real.

Here is a table to help you decide:

| Application Domain | Priority Metric | Why? |

|---|---|---|

| Fraud Detection | Precision | Avoid annoying users with false alarms |

| Medical Diagnostics | Recall | Catch every possible disease |

| Product Recommendations | Precision | Show only relevant items |

| Cybersecurity | Recall | Detect every possible threat |

You can use the F1 score to help with balancing precision and recall. The F1 score combines both metrics into one number. This helps you compare models and pick the best one for your needs. Many machine vision projects use mean average precision (mAP) to compare models across different classes and thresholds.

You have seen how recall helps your machine vision system find almost every defect or object. High recall means you miss fewer problems, which keeps your results reliable. Look at the table below to see how perfect recall leads to strong accuracy in real-world tasks:

| Pipeline Stage | Accuracy (%) | Precision (%) | Recall (%) | F1 Score (%) |

|---|---|---|---|---|

| String Detection | 100.0 | 100.0 | 100.0 | 100.0 |

| Logo Defect Detection | 97.9 | 95.5 | 100.0 | 97.7 |

| Anomaly Detection on Characters | 99.8 | 99.6 | 100.0 | 99.8 |

When you work on real projects, like sorting trash or checking products, you need both recall and precision. These metrics help you spot every issue and keep mistakes low. Keep learning about recall and precision to build better, safer machine vision systems! 🚀

FAQ

What is the difference between recall and accuracy?

Recall shows how many real objects your system finds. Accuracy tells you how many total predictions are correct. You can have high accuracy but low recall if your system misses many real objects.

How can you improve recall in your machine vision system?

You can improve recall by using more training data, adjusting your model’s threshold, or choosing better features. Try data augmentation, like flipping or rotating images, to help your model learn more patterns.

Why does high recall sometimes cause more false positives?

When you focus on finding every real object, your system may also pick up things that are not real. This increases false positives. You need to balance recall and precision for the best results.

Is recall always the most important metric?

No, recall is not always the most important. In some cases, you want high precision instead. For example, in spam detection, you do not want to mark real emails as spam. Choose the metric that fits your goal.

See Also

Essential Frame Capture Devices For Advanced Vision Systems

Important Insights Into Computer And Machine Vision Technologies

Fundamental Principles Behind Edge Detection In Vision Systems

Complete Overview Of Industrial Automation Using Machine Vision

Understanding Core Elements Of Sorting Using Vision Technology