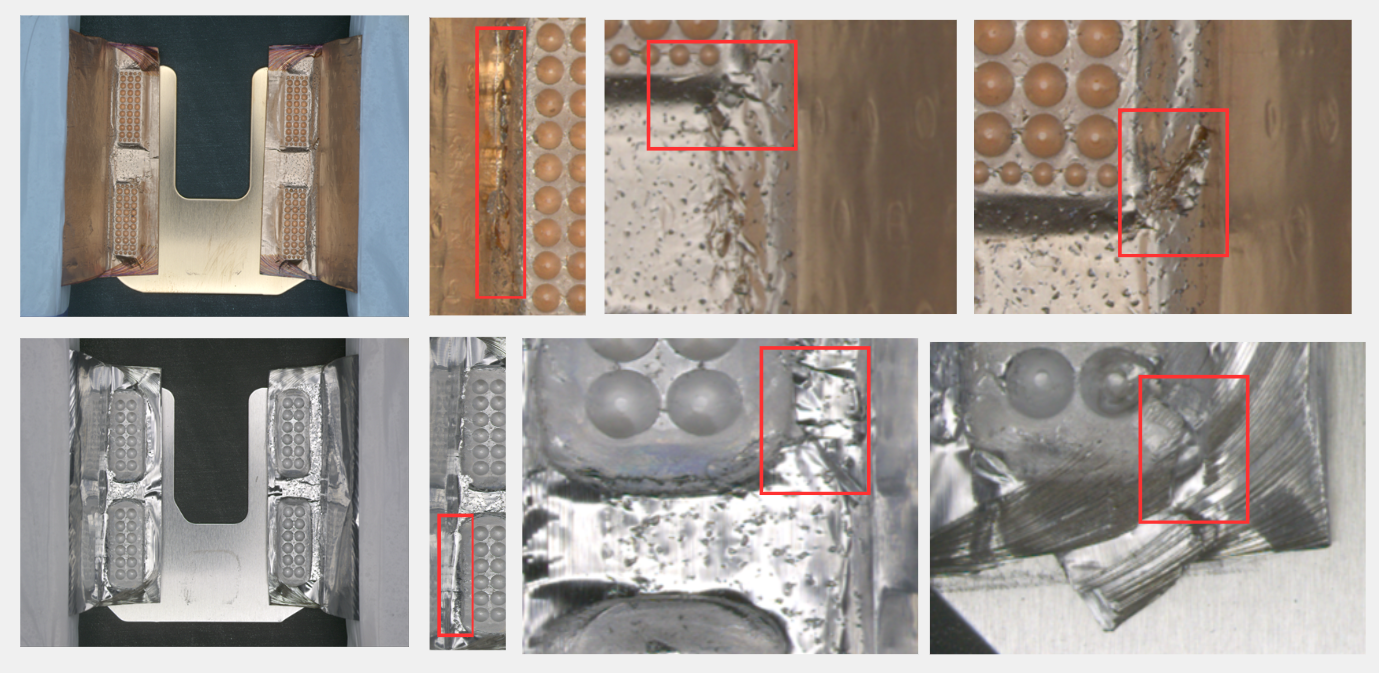

In the battery industry, defects like tearing at the welding edge, tab root, and underside are hard to detect due to occlusion and surface reflections, challenging traditional vision systems.

Customer Objectives

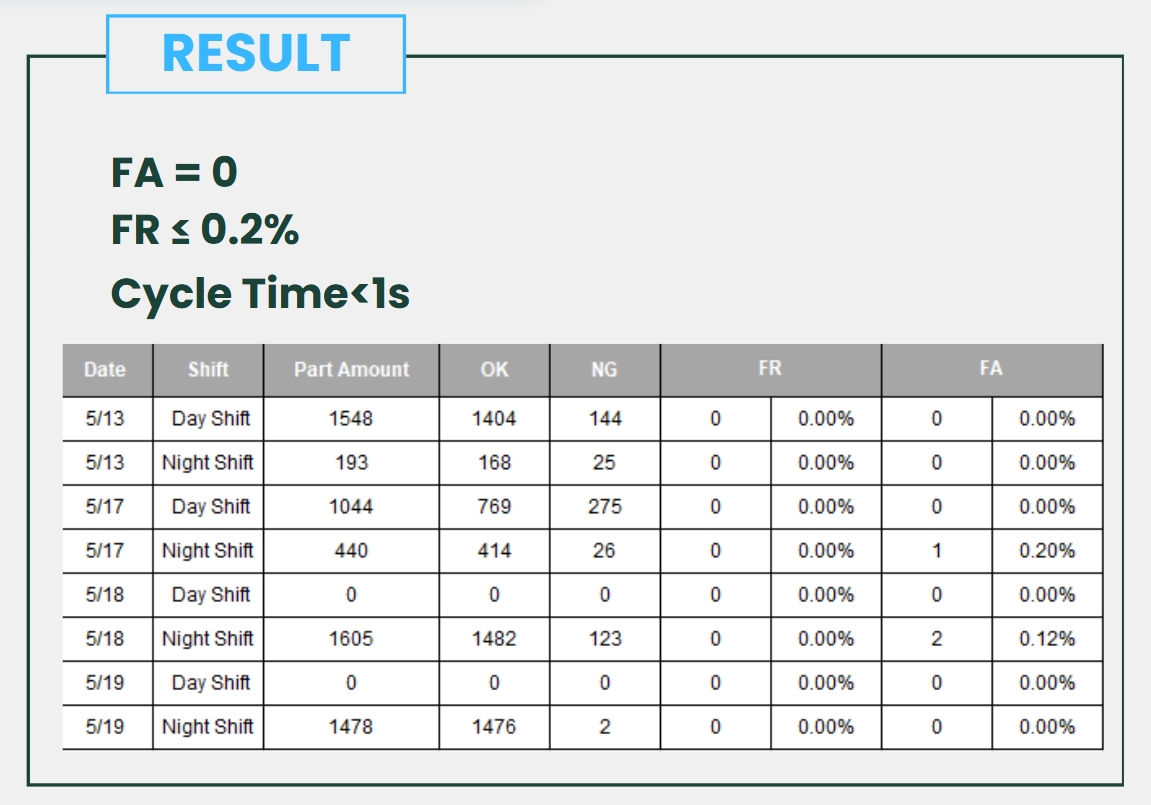

The customer requires defect detection for tab tearing on the front surface of a battery cell product, with a particular focus on identifying severe defects where the tearing length exceeds 2mm for both positive and negative electrodes. The inspection cycle time must be controlled within 1.1 seconds, demanding high-speed and high-precision detection capabilities.

Product & Defects Images

Solutions:

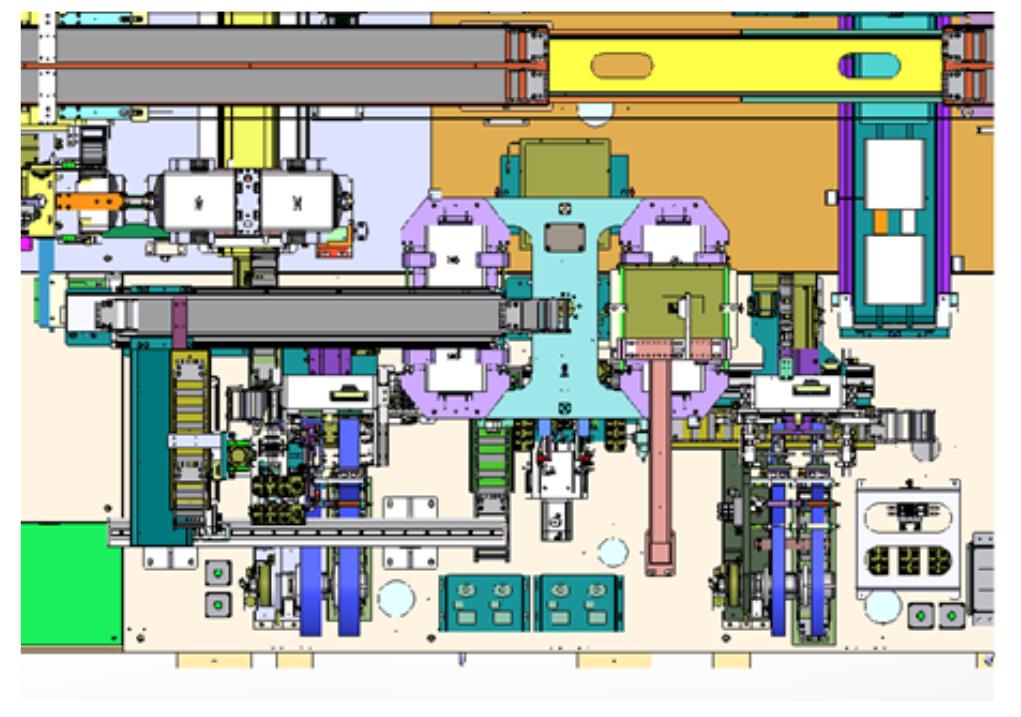

Hardware: OptiX *2 +CorteX Central *1 +CorteX Edge *1

Conclusion

Through optimized imaging solutions and deep learning algorithms, UnitX achieved zero FR and maintained a FA below 0.5%, fully meeting the customer’s requirements for high stability and effectively replacing manual inspection.