One-stage object detection machine vision systems revolutionize how you approach the object detection task. These systems simplify the process by combining classification and localization into a single step, enabling accurate and fast object detection. Unlike traditional methods, they rely on deep learning models to generate object detection predictions directly, ensuring minimal delays. This makes them ideal for real-time applications like automated caries detection and other computer vision tasks. Their efficiency allows you to implement them in scenarios requiring speed and precision, such as industrial automation and surveillance systems.

Key Takeaways

- One-stage object detection does two jobs at once: finding and identifying objects. This makes it faster and better for real-time use.

- These systems need less computer power. They can work on small devices like drones and tiny computers without losing quality.

- Models like YOLO and RetinaNet are very accurate and quick. They are great for busy places like traffic monitoring or factory machines.

- One-stage systems use a grid to find objects. This skips extra steps, making them faster and easier to use.

- These detectors can grow and change easily. They work well for big projects in industries like robots and checking product quality.

Comparing One-Stage and Two-Stage Object Detection

Key Differences Between One-Stage and Two-Stage Methods

When comparing one-stage and two-stage object detection methods, the primary distinction lies in their approach to detecting objects. One-stage object detectors streamline the process by combining classification and localization into a single step. This makes them faster and more efficient, especially for real-time applications. In contrast, two-stage methods, such as Faster R-CNN, rely on a region proposal network to identify potential object locations before performing classification and localization. While this two-step process enhances accuracy, it increases computational complexity and slows down inference times.

To illustrate the speed differences, consider the following comparison:

| Detection Method | Speed (Inference Time) | Accuracy |

|---|---|---|

| YOLO (One-Stage) | Up to 300 times faster | 63.4% |

| Fast R-CNN (Two-Stage) | Slower processing times | 70% |

Two-stage methods excel in scenarios requiring high precision, such as detecting small objects or handling crowded scenes. However, they demand large labeled datasets and significant computational resources, making them less practical for real-time applications.

Advantages of One-Stage Object Detectors for Machine Vision

One-stage object detectors offer several advantages that make them ideal for machine vision systems. Their simplified architecture reduces computational complexity, enabling faster processing speeds. This efficiency is particularly valuable in real-time object detection tasks, where detecting multiple objects quickly is crucial. For example, YOLO and RetinaNet are popular one-stage models that balance speed and accuracy effectively.

Key benefits include:

- Faster inference times, making them suitable for real-time applications.

- Lower hardware requirements, allowing deployment on edge devices.

- Scalability for large-scale systems, such as traffic monitoring or industrial automation.

RetinaNet, a single-stage object detector, uses innovative techniques like Focal Loss to improve accuracy by focusing on hard-to-classify examples. Its Feature Pyramid Network enhances detection across various scales, while specialized sub-networks for classification and box regression contribute to its efficiency. These advancements demonstrate how one-stage object detection models can achieve state-of-the-art performance in machine vision applications.

Challenges of Two-Stage Methods in Real-Time Scenarios

Two-stage object detection methods face significant challenges in real-time scenarios. Their reliance on region proposal networks increases computational expense, making them impractical for applications requiring immediate results. For instance, R-CNN models are known for their high accuracy but struggle with speed and efficiency.

The following table highlights some common challenges:

| Challenge | Description |

|---|---|

| Computational Expense | R-CNN, a two-stage method, is noted for being computationally expensive, making it impractical for real-time applications. |

| Speed and Efficiency Limitations | Two-stage methods generally have practical limitations in speed and efficiency compared to single-stage methods. |

| Complex Scene Handling | There are ongoing challenges in dealing with complex scenes while maintaining real-time performance. |

While two-stage methods excel in accuracy, their inability to handle real-time requirements limits their use in scenarios like autonomous vehicles or industrial robotics. One-stage object detection machine vision systems address these challenges by offering faster processing speeds and simplified architectures, making them more suitable for dynamic environments.

Core Principles of One-Stage Object Detection

Grid-Based Detection and Prediction Mechanisms

One-stage object detection systems divide the input image into a grid, where each cell predicts objects within its boundaries. This grid-based approach eliminates the need for region proposals, speeding up the detection process. Models like YOLO and SSD leverage this mechanism to achieve real-time performance. By skipping intermediate steps, these systems balance speed and accuracy effectively.

You can see how this method works in practice. Each grid cell predicts bounding boxes and assigns confidence scores to indicate the likelihood of an object’s presence. This streamlined process reduces computational overhead, making it ideal for applications requiring immediate results.

Key advantages of grid-based detection include:

- Faster inference times due to the absence of region proposal networks.

- Simplified architecture that supports real-time detection.

- Efficient handling of multiple objects in a single pass.

Role of Anchors and Confidence Scores

Anchors play a crucial role in improving detection accuracy. These predefined bounding boxes help the model predict object locations more precisely. By comparing predicted boxes to anchors, the system adjusts its predictions to align with the training image data. Confidence scores further refine this process by quantifying the likelihood of an object’s presence in a predicted box.

Studies show that anchors significantly influence detection accuracy. For example, participants adjusted their predictions to about 60% of the anchor’s value, demonstrating the anchoring effect. This adjustment aligns predictions with numeric hints, enhancing the model’s reliability. Confidence scores complement this by ensuring the system prioritizes high-probability detections, reducing false positives.

Combining Classification and Localization in Single-Stage Object Detectors

One-stage object detectors integrate classification and localization into a single step. This unified approach enhances speed and efficiency, making it suitable for real-time applications. Models like YOLO and SSD exemplify this principle by simultaneously predicting object classes and spatial positions.

OverFeat demonstrates the benefits of this integration. Its architecture allows the model to predict both class and location in one pass, reducing computational complexity. This approach ensures faster processing while maintaining accuracy. By combining classification and localization, one-stage systems optimize their loss function to balance precision and recall effectively.

Key benefits of this integration include:

- Faster processing speeds for real-time applications.

- Reduced computational demands, enabling deployment on edge devices.

- Improved accuracy through optimized loss function design.

Practical Benefits of One-Stage Object Detection

Speed and Efficiency in Machine Vision Applications

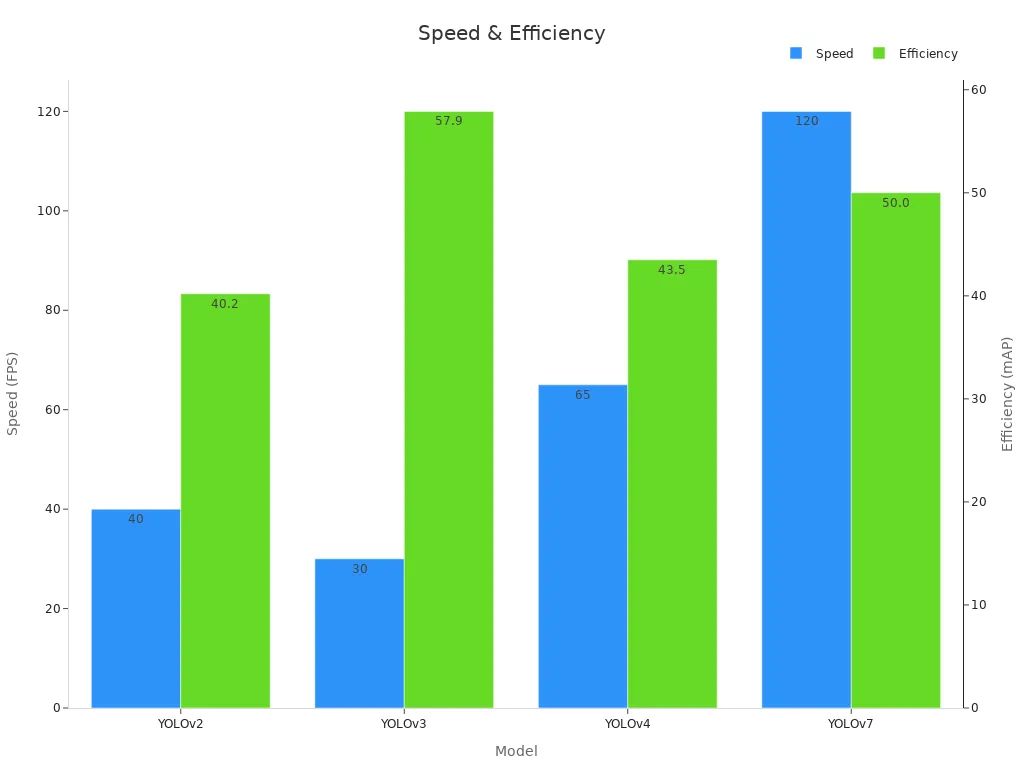

Speed and efficiency define the core strengths of one-stage object detectors. These systems process images in a single pass, eliminating intermediate steps like region proposal generation. This streamlined approach enables real-time performance, making them ideal for dynamic environments such as traffic monitoring or industrial robotics. Models like YOLOv2, YOLOv3, and YOLOv7 demonstrate remarkable advancements in speed and accuracy, as shown in the table below:

| Model | Speed (FPS) | Efficiency (mAP) |

|---|---|---|

| YOLOv2 | 40 | 40.2% |

| YOLOv3 | 30 | 57.9% |

| YOLOv4 | 65 | 43.5% |

| YOLOv7 | 120 | 50.0% |

These metrics highlight how one-stage object detection models balance speed and efficiency, ensuring reliable performance in real-time applications. Faster inference times allow you to deploy these systems in scenarios requiring immediate results, such as autonomous vehicles or surveillance systems.

Lower Hardware Requirements for Deployment

One-stage object detection machine vision systems excel in environments with limited hardware capabilities. Their single-pass approach reduces computational demands, enabling deployment on edge devices like drones or embedded systems. Unlike multi-stage networks, which require significant processing power, one-stage models achieve high accuracy with fewer resources.

For example, YOLO achieves 72.1% mAP@[0.5:0.95] on PASCAL VOC and MS COCO datasets while using 37% fewer parameters compared to YOLOv4-tiny. It also requires 19% fewer FLOPs, improving IoU by 4.02% and average precision by 2.8%. On PASCAL VOC, YOLO improves mAP@[0.5:0.95] by 0.3% while requiring 61% fewer FLOPs and running almost twice as fast. These statistics confirm the suitability of one-stage object detectors for hardware-constrained environments, allowing you to deploy them without compromising performance.

Scalability for Large-Scale Systems

Scalability is another key advantage of one-stage object detection systems. Their simplified architecture and efficient processing make them adaptable to large-scale applications, such as city-wide traffic monitoring or industrial automation. Single-stage object detectors like SSD integrate prediction mechanisms that eliminate the need for separate region proposal networks, enhancing speed and precision.

The table below highlights the scalability benefits of SSD:

| Evidence Description | Key Benefits |

|---|---|

| SSD’s integrated prediction mechanism | Eliminates the need for a separate RPN, enhancing processing speed and precision in object localization and classification. |

| Multi-scale functionality of SSD | Allows detection across various resolutions, improving adaptability to different object sizes and enhancing performance on low-resolution images. |

| Real-time application of SSD | Suitable for embedded systems due to its small number of parameters, enabling high inference speed and adequate accuracy for tasks like human lower body detection. |

These features make one-stage object detection models highly versatile, allowing you to scale them across diverse applications without sacrificing efficiency or accuracy. Whether you’re managing a large manufacturing facility or monitoring urban traffic, these systems provide the flexibility and reliability needed for complex machine vision tasks.

Real-World Applications of One-Stage Object Detection Machine Vision Systems

Autonomous Vehicles and Traffic Monitoring

One-stage object detectors play a vital role in autonomous vehicles and traffic monitoring systems. Their ability to process images quickly ensures real-time detection of vehicles, pedestrians, and road signs, enhancing safety and navigation. Models like YOLOv8 excel in recognizing objects under diverse conditions, improving situational awareness for autonomous vehicles. For example, YOLOv4 achieves a 2.06% improvement in average accuracy on the KITTI dataset and a 2.95% improvement on the BDD dataset. Its inference speed surpasses 58 FPS, enabling real-time detection in dynamic environments.

Traffic monitoring systems also benefit from one-stage object detection. Studies show YOLOv5 achieves a detection accuracy of 98.1% in real-time vehicle counting, outperforming other systems like Yolo4-CSP (94.76%) and VC-UAV (95.54%). These advancements make one-stage object detection machine vision systems indispensable for modern transportation networks.

Robotics and Industrial Automation

In robotics and industrial automation, one-stage object detectors streamline operations by enabling precise and fast object recognition. This capability improves productivity and safety in environments requiring real-time decision-making. For instance, Jan et al. (2022) demonstrated how one-stage models enhance industrial automation by optimizing workflows and reducing errors. Similarly, Gallo et al. (2023) showcased the effectiveness of YOLOv7 in detecting crop weeds, proving its adaptability to agricultural robotics.

The table below highlights key findings from case studies:

| Case Study | Application Area | Key Findings |

|---|---|---|

| Jan et al. (2022) | Industrial Automation | Improved productivity and safety in real-time. |

| Gallo et al. (2023) | Agriculture | Effective detection of crop weeds using YOLOv7. |

These examples illustrate how one-stage object detectors transform industries by enabling efficient and accurate object detection.

Quality Control and Defect Detection in Manufacturing

Manufacturing processes rely on one-stage object detection systems to identify defects and ensure product quality. These systems excel at detecting small objects and subtle flaws, making them ideal for quality control tasks. For example, YOLO integrates classification and localization into a unified model, achieving high accuracy in defect detection. Advanced methods like SD-Net and YOLOv5 further enhance performance by incorporating innovative features such as spatial pyramid modules and transformer-based global feature extraction.

The table below summarizes improvements in defect detection accuracy:

| Method | Description | Accuracy Improvement |

|---|---|---|

| SD-Net | Utilizes Yolov3 with Res-Net for metal surfaces. | High accuracy. |

| YOLOv5 | Introduced transformer modules for feature fusion. | Enhanced detection. |

These advancements demonstrate how one-stage object detection systems revolutionize manufacturing by ensuring precision and reliability in defect detection.

One-stage object detection machine vision systems are reshaping the landscape of machine vision with their unmatched speed and simplicity. These systems excel in real-time applications by reducing computational demands and delivering rapid, accurate results. Their streamlined architecture makes them ideal for robotics, surveillance, and industrial automation, where efficiency is paramount.

📈 Future Trends:

- The Vision Transformers market is projected to grow from $280.75 million in 2024 to $2,783.66 million by 2032, with a CAGR of 33.2%.

- The Video Analytics Market is expected to rise from $8.3 billion in 2023 to $22.6 billion by 2028, reflecting a CAGR of 22.3%.

Recent advancements in single-stage detectors have significantly improved their speed and accuracy. For instance, YOLO achieves detection speeds nearly 300 times faster than two-stage methods, while RetinaNet demonstrates a 6–9% increase in average precision with ResNet-101-FPN and ResNeXt-101-FPN. These innovations ensure that one-stage systems remain at the forefront of scalable and efficient machine vision solutions.

FAQ

What is one-stage object detection, and how does it differ from two-stage methods?

One-stage object detection combines classification and localization into a single step. It eliminates region proposal networks, making it faster and simpler. Two-stage methods, like Faster R-CNN, use a region proposal network first, which increases computational complexity but improves accuracy for tasks like dental caries detection.

Can one-stage object detection systems detect dental caries effectively?

Yes, one-stage systems can detect dental caries with high accuracy. Models like YOLO integrate advanced feature extractors to identify carious regions in dental images. Their speed and efficiency make them suitable for real-time dental caries detection in clinical settings.

Why are feature extractors important in one-stage object detection?

Feature extractors identify key patterns in images, enabling accurate object detection. In dental applications, they help pinpoint carious areas by analyzing texture and shape. Advanced feature extractors improve accuracy, ensuring reliable results for tasks like dental caries detection.

Are one-stage object detectors scalable for large dental datasets?

Yes, one-stage detectors handle large datasets efficiently. Their streamlined architecture processes images quickly, making them ideal for dental caries detection across extensive datasets. Scalability ensures consistent accuracy, even in diverse dental imaging scenarios.

How do one-stage systems balance speed and accuracy in dental applications?

One-stage systems optimize their loss functions to balance speed and accuracy. They use techniques like grid-based detection and confidence scoring to ensure reliable results. This makes them ideal for dental caries detection, where precision and efficiency are crucial.

See Also

Exploring Object Detection Techniques in Today’s Vision Systems

Capabilities of Machine Vision Systems in Identifying Defects

The Role of Thresholding in Machine Vision Technology