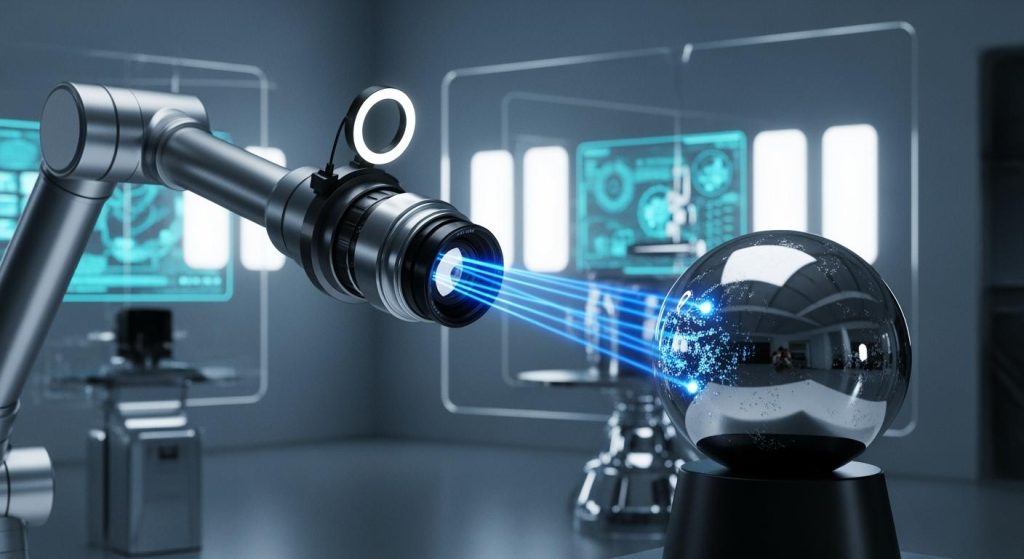

In 2025, you face a rising demand for perfect product quality. Standard inspection methods often miss tiny flaws. A surface reflectance analysis machine vision system offers a better solution. This technology provides a deeper level of analysis. It improves your inspection by looking at how light interacts with a surface. This detailed reflectance analysis is key for superior quality inspection.

Industry Insight: The machine vision market shows significant growth. Projections indicate an increase from USD 15.83 billion in 2025 to USD 23.63 billion by 2030, highlighting the industry's push for advanced inspection technologies.

Key Takeaways

This system finds tiny flaws that regular cameras miss. It sees scratches and coating problems.

It helps tell the difference between real defects and harmless marks. This saves money by reducing waste.

The system works well even when factory lights change. It uses special lights to get good data.

It can sort materials that look the same. For example, it can tell different plastics apart.

This technology makes factory lines work better and faster. It checks products in real-time.

Enhanced Inspection with a Surface Reflectance Analysis Machine Vision System

You can achieve a superior level of quality control with a surface reflectance analysis machine vision system. This technology moves beyond simple imaging. It provides a detailed analysis of object light interactions. This advanced inspection is crucial for many applications. The system’s lighting techniques enable powerful image contrast enhancement.

Pinpointing Microscopic and Subtle Flaws

Standard cameras often miss tiny defects. Your inspection process can overcome this. A surface reflectance analysis machine vision system captures how light reflects off a surface. This reflectance data reveals micro-scratches, coating variations, and low-contrast blemishes. The analysis of surface reflectivity is very precise. For example, in automotive applications, this inspection method detects faint oil traces on metal before sealing engine parts, boosting reliability. The right machine vision lighting is essential for these applications. Proper illumination and lighting analysis and development are key. The system uses specific LED lighting techniques for optimal data collection.

Differentiating Cosmetic vs. Functional Defects

Your production line may generate high false positives. This happens when a system mistakes a harmless smudge for a critical crack. This detailed analysis helps you tell the difference. By understanding the surface properties from reflectance data, your inspection can classify defects accurately. This reduces unnecessary scrap and saves money. AI-driven systems have cut weekly false rejects from 12,000 to just 246, and you can reduce scrap by 15-30%. Better data leads to better performance.

Overcoming Challenging Machine Vision Lighting

Factory floors often have variable illumination. This creates challenges for standard inspection. A key benefit is estimating surface reflectivity even with changing machine vision lighting. The system uses several techniques. It may use calibration targets or adjust sensor settings for the immediate inspection environment. Some applications use a second sensor to measure ambient lighting and normalize the reflectance data. For highly reflective surfaces, you can use ray-tracing simulations. This helps model the inspection and generate diverse data to train the system for complex applications. This lighting analysis and development ensures your data is reliable. The immediate inspection environment requires robust LED lighting. The right machine vision lighting and illumination techniques make your data consistent. The immediate inspection environment benefits from this advanced analysis of reflectance. The LED lighting and machine vision lighting are critical for image contrast enhancement. These applications require stable machine vision lighting. The LED lighting provides the necessary illumination. Good lighting and image contrast enhancement are vital. The LED lighting techniques improve image contrast enhancement. The machine vision lighting and illumination data are used for many applications. The LED lighting and reflectance data improve image contrast enhancement. The LED lighting and machine vision lighting techniques are perfect for these applications. The LED lighting provides consistent illumination. The reflectance data is key for image contrast enhancement.

Precise Material Analysis and Characterization

You can move beyond simple pass/fail inspection. A surface reflectance analysis machine vision system allows you to understand the fundamental properties of your materials. This detailed analysis provides quantitative data, not just images. This data is crucial for ensuring materials meet exact specifications across many applications. The right LED lighting techniques and illumination are vital for this level of inspection.

Quantifying Surface Finish and Reflectance

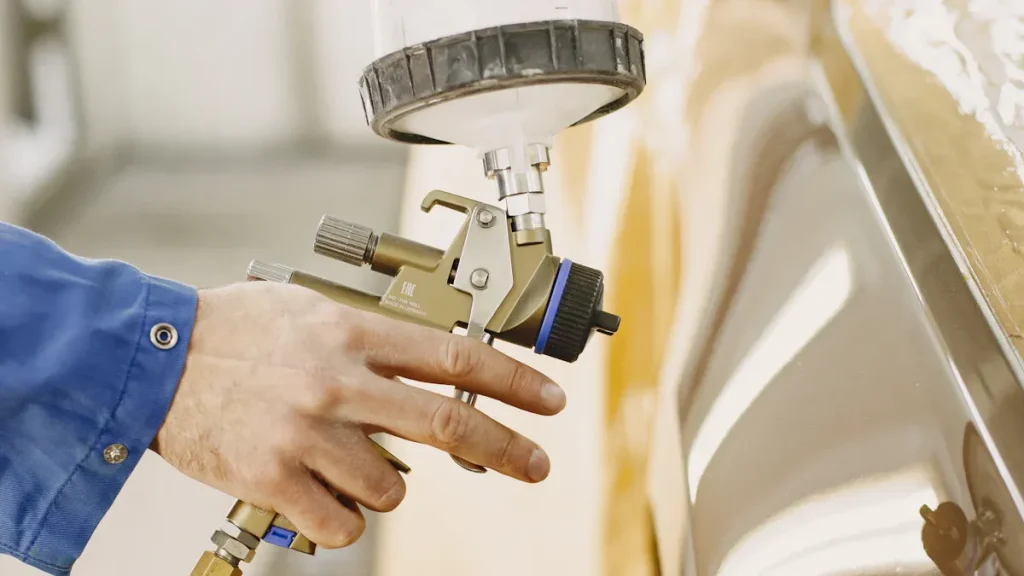

You need to measure surface quality with precision. This is critical in industries like aerospace, automotive, and medical devices, where finish affects performance, safety, and durability. Your inspection process can quantify surface finish by capturing detailed reflectance data. The system uses specific LED lighting and illumination techniques to perform radiometric and photometric measurement. This analysis measures how light scatters from a surface, providing a numeric value for its texture and gloss.

Pro Tip: This quantitative analysis of surface reflectivity is essential for optical systems and energy-efficiency applications. It ensures that components like lenses and reflective coatings perform exactly as designed by minimizing light scatter. The data from this inspection is invaluable.

The system captures this reflectance data using advanced sensors and lighting. These techniques provide a complete analysis of the surface. This inspection is useful for many applications. The data from the LED illumination and lighting techniques is very reliable. This inspection uses specific LED lighting. The data is used in many applications. The lighting and illumination techniques are key for this inspection. The data from the LED lighting is used for many applications.

Sorting Materials with Similar Appearances

Your standard vision system may struggle to sort materials that look alike. A surface reflectance analysis machine vision system solves this problem. It uses specific lighting and illumination techniques to reveal unique material signatures from reflectance data. This analysis allows you to differentiate materials that are visually identical. This inspection is perfect for many applications. The LED lighting and illumination data is key for this inspection.

This capability has powerful applications:

Plastic Sorting: You can distinguish between different polymers like Polypropylene (PP) and Polystyrene (PS). Even if they have the same color, their unique reflectance in the near-infrared spectrum allows for accurate sorting in recycling applications. This analysis uses specific LED lighting techniques.

Metal Alloy Identification: You can sort metal alloys that appear identical. Different metals like aluminum and copper have distinct surface reflectivity curves. The system’s analysis of this reflectance data enables precise sorting, improving purity in metal recovery operations.

This inspection relies on consistent LED lighting and illumination. The data from these techniques is used for many applications. The lighting and illumination data is used for many applications. This inspection uses specific LED lighting techniques. The data from the lighting and illumination is used for many applications.

Boosting Production Line Efficiency and Yield

You can transform your factory’s output with a surface reflectance analysis machine vision system. This technology directly improves your operational performance. It automates difficult inspection tasks and provides real-time data for better process control. Many industrial applications benefit from this advanced inspection. The right LED lighting and data analysis are crucial for these applications.

Automating Complex Surface Inspection

You can reduce reliance on manual inspection. Human inspectors can miss an average of 15% of defects, and this rate increases with fatigue. Automated inspection, however, achieves detection rates over 95%. This automation lowers labor costs and frees your team for more complex analysis. The system’s LED lighting provides consistent data for many applications. This inspection is vital for quality.

This technology excels at difficult jobs. For example, you can automate the inspection of complex materials like carbon fiber composites. The system uses specific LED lighting to gather precise reflectance data. This data allows for a detailed analysis of the surface. This inspection is useful for many applications. The LED lighting and data are key for these applications. The LED lighting provides the data for this inspection. The LED lighting and data are used in many applications. The LED lighting and data are used in many applications. The LED lighting and data are used in many applications.

Enabling Real-Time, In-Line Quality Control

You can integrate high-speed inspection directly into your production line. This in-line quality control provides immediate feedback without creating bottlenecks. The system’s rapid analysis of reflectance data flags issues instantly. This allows you to make immediate adjustments. This inspection is useful for many applications. The LED lighting and data are used in many applications.

Real-World Impact: Companies using similar in-line quality control have seen a 25% increase in production and a 2x boost in overall capacity. This immediate data helps you resolve part failures from day one.

This real-time data on surface reflectance and part quality helps you increase throughput. You can continuously track performance and identify lagging stations. This detailed inspection ensures every product meets standards. The analysis of reflectance data is key for this inspection. The LED lighting provides the data for this inspection. This inspection is useful for many applications.

You can achieve superior automated inspection, precise material analysis, and greater operational efficiency. This detailed reflectance inspection gives you a clear advantage. In 2025, this advanced reflectance analysis is essential for your business. It helps you meet higher quality standards. This improved inspection ultimately boosts your profitability and strengthens your competitive edge in the market.

FAQ

What is a surface reflectance analysis machine vision system?

This advanced inspection system uses special LED lighting. It analyzes how light reflects from a surface. This detailed inspection provides more information than a standard camera. The LED lighting is crucial for many applications. The LED lighting makes the inspection powerful.

How is this inspection different from standard 2D/3D inspection?

Standard inspection sees shapes. This advanced inspection analyzes material properties from reflectance data. It uses specific LED lighting to understand the surface. This detailed inspection is better for complex applications. The LED lighting makes this inspection unique.

Can this system work with difficult lighting conditions?

Yes, this inspection works in varied lighting. The system uses smart techniques and specific LED lighting. It handles changing factory lighting well. This ensures your inspection is always reliable. The LED lighting is essential for a stable inspection.

What are the main applications for this inspection technology?

You can use this inspection for many applications. It excels at finding flaws on shiny surfaces. The LED lighting helps this inspection. Other applications include sorting plastics and checking coatings. The LED lighting is key for these applications. The LED lighting supports many applications.